Centrifugal Pumps – “Clipping the Tips”

| R. L. Deppmann regularly receives questions when a field problem pops up. Here is an example call from an industrial user with a pump issue.

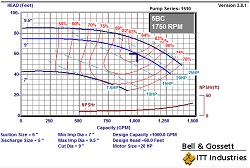

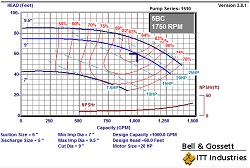

There is an existing Bell and Gossett model 1510-5BC with a capacity of 1000 GPM at 60 foot head using a 25 HP, 1750 RPM motor and a 9” cut impeller. This was a constant speed constant flow cooling pump. The owner wants to change one of the machines and the change is short term, so they want to keep the cost as low as possible. Changing out the pump would involve re-piping and new electrical causing down time and a great deal of cost for an operation which will change in the fall. The balance contractor indicated they were short on head. The renovation required 80 feet at the 1000 GPM flow. What could they do?

|

|

|

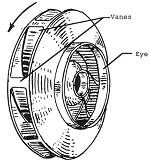

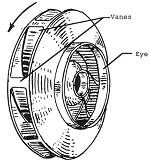

Clearly by changing the impeller to 9-1/2” the capacity will be increased to 1000 GPM at 74 feet on this curve. The next thing could be to look at a change in the motor. A premium efficiency 25 HP motor would be 1785 RPM and this would raise the head to 78 feet at 1000 GPM and be very close to the full load amps.The last item is a little known procedure referred to by many names but we call it, “clipping the tips”. An impeller has a series of vanes shown in the figure below. If we under file the impeller, removing some of the brass, there is a larger area between the “Tips” of the impeller vanes. This causes a slightly higher discharge head. Based on experience at Bell and Gossett we can expect to get 2% to 4% higher head as a result of this change. |

This is not something you would use to specify a new pump, but can be helpful with an existing project where the head is close, but not quite there. It is a modification with varying results but can make a difference. The machining should be done by the manufacturer or their representative or you may end up with less capacity rather than more. You also have to make sure there is enough horsepower available. In this case the efficiency of the pump is about 83.5% so the brake horsepower would be BHP= (1000 X 100) / (83.5 X 3960) = 24.2. The owner would have to understand the motor may operate in the service factor once this change is complete.

Obviously we could have looked at a variable speed drive with a higher speed motor or a “booster” pump as solutions but then I would not have had a chance to tell you about the little known process referred to as, “clipping the tips”. |

|

Disclaimer: R. L. Deppmann and it’s affiliates can not be held liable for issues caused by use of the information on this page. While the information comes from many years of experience and can be a valuable tool, it may not take into account special circumstances in your system and we therefore can not take responsibility for actions that result from this information. Please feel free to contact us if you do have any questions.

Archives – Click here for Past Articles