When selecting and specifying a steam boiler feed unit or deaerator, the engineer must pay attention to the controls. Level controls at the boilers must match the pump controls on the feedwater system. Today, the R. L. Deppmann Company offers many choices which we have used in Michigan and Northern Ohio.

When selecting and specifying a steam boiler feed unit or deaerator, the engineer must pay attention to the controls. Level controls at the boilers must match the pump controls on the feedwater system. Today, the R. L. Deppmann Company offers many choices which we have used in Michigan and Northern Ohio.

Please excuse the length of this blog. It is long but easy to read and will clearly get the concepts of pump and boiler control across. If you understand the content in this article, you can apply it to any system you wish to design.

Some Thoughts about Boiler Feed Pump Control

The boiler feed unit will have some number of pumps including standby. There may be one or more boilers. The goal is to make sure the boilers have the correct level controls, and the pump system will recognize the call for water and start the correct pump. This seems elementary but it will require coordination between the boiler, boiler feed pumps, and the installing contractors. This is where the engineer’s specification and drawings become critical.

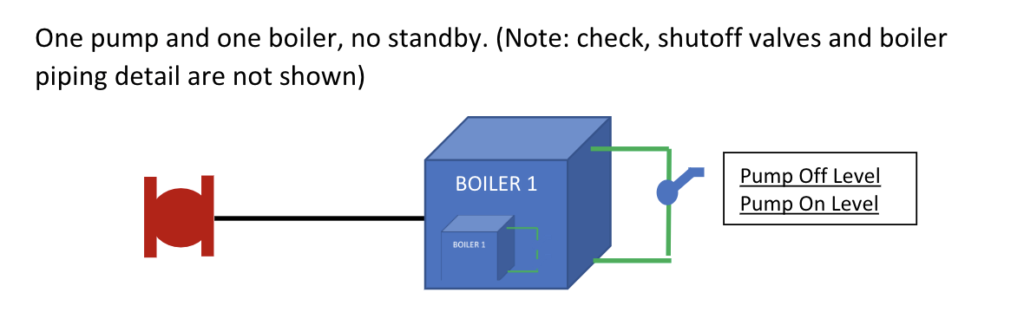

Start with the Single Boiler

Starting with the control of a single boiler may seem simple but it will get the idea of control logic required in the feedwater system as well as the level controls on the boilers.

It cannot get any simpler. The pump panel will have a “hand-off-auto” switch so we can turn the pump on manually, disengage the pump, or control automatically. The boiler must have a single level control to activate the pump on low level and turn the pump off on high level.

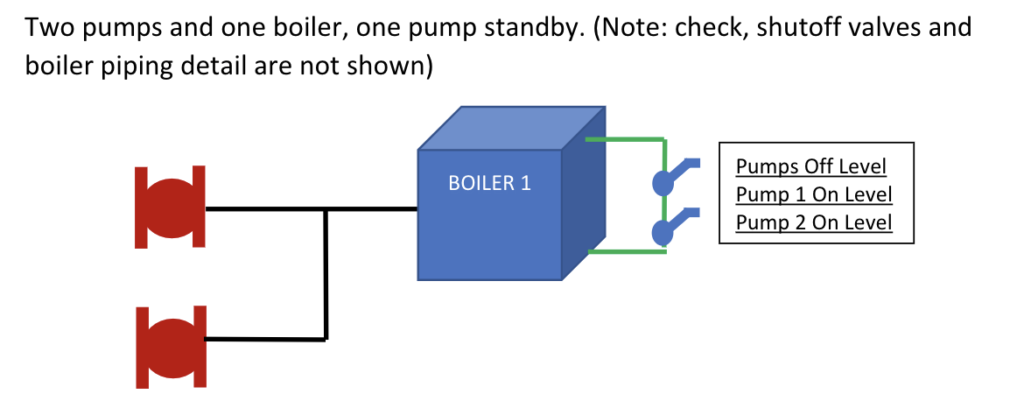

Now we add a standby pump.

The important thing here is the second level control on the boiler. Something must tell the second pump or standby that the first pump is not keeping up. There must be another level control on the boiler. It will either be supplied by the boiler manufacturer or the contractor will have to install it.

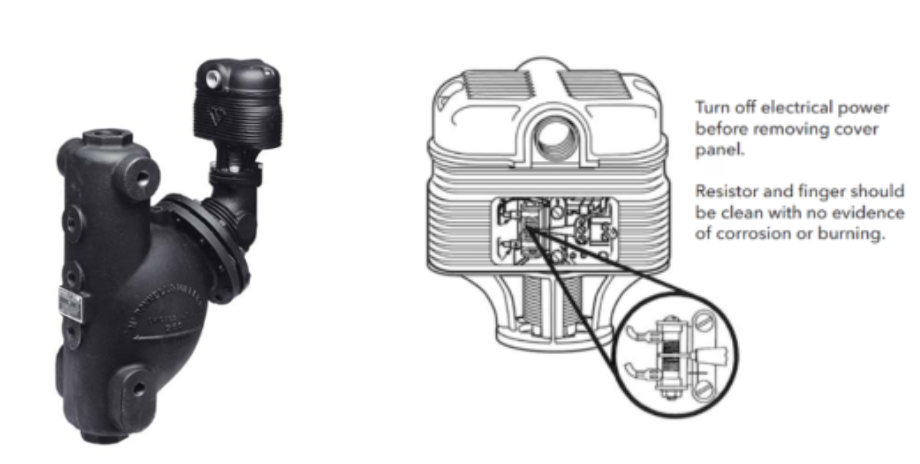

Each pump will have a “hand-off-auto” switch with an electrical alternator so we can turn the pump on manually, disengage the pump, or control automatically. The electric alternator will assure equal wear on the pumps. The boiler must have two level switches to activate the pumps on low level and turn the pumps off on high level. It is not wise to use the low water cutoff switch as a pump control. I don’t recommend using a safety switch as part of an operating pump strategy. Let the boiler manufacturer figure out how and what McDonnell Miller pump controls to use.

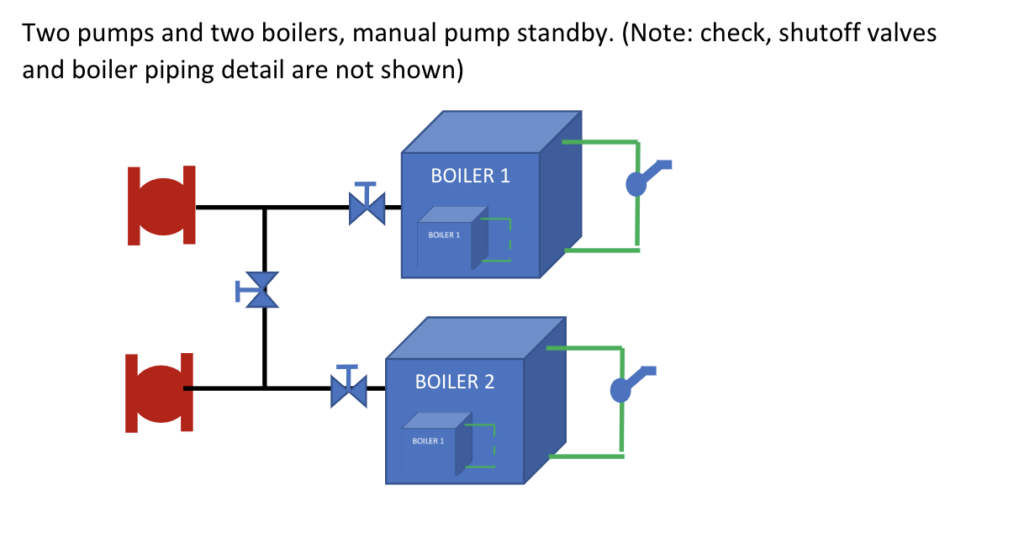

Two Boiler, Feed Pump Control with Manual Standby

Most larger buildings will have two or more boilers. They may have standby boilers or use all of the boilers in very cold weather. Each boiler must be able to activate the appropriate pump or pumps. The difference now is to make sure the water gets in the right boiler.

Pump 1 serves boiler 1. Pump 2 serves boiler 2. The level control on each boiler operates its respective pump. The pipe between the two boilers, along with the boiler shutoff valves, will allow the owner to manually have pump 2 serve boiler 1 and vice versa. This control would indicate to me that one of the boilers is standby most of the time.

The challenge, again, is to make sure the controls match the intended sequence. The pump panel will have boiler switches marked “Hand-Off-Pump 1- Pump 2.” This will assure the contact closure will start the right pump after the owner has opened and closed valves.

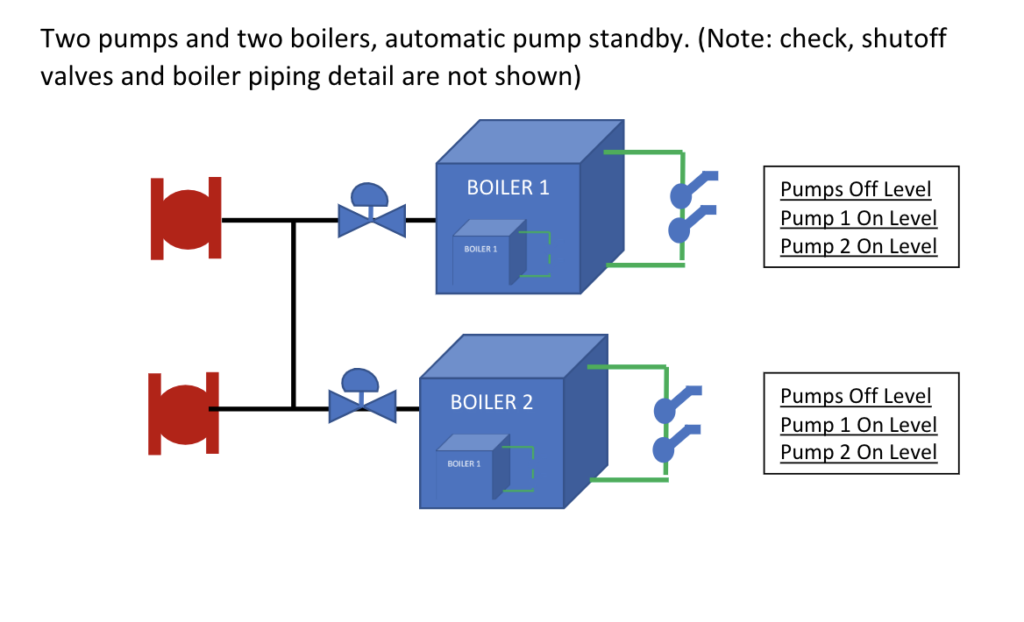

Multiple Boiler & Feed Pump Controls with Automatic Standby

The next two schemes may be used for many boilers and pumps. These are two that I regularly recommend to engineers and provide for school and health care installations.

The challenge is to determine where the condensate will flow when it is pumped into a common header. The water will want to go to the boiler with the least pressure which will be the “off” boiler. That will not work. We must employ valving to get the water into the operating boiler that needs water.

Two pumps and two boilers with automatic standby is one I use regularly. This can even apply to three or more boilers and pumps. This system still employs on-off level controls at the boilers. When the boiler calls for water, the pump control panel will start to open a 2-position electric control valve with an end switch. When the valve is partially open, the end switch will make and start the appropriate pump.

The pump will satisfy the level in the boiler that was calling for water. When the level is satisfied, the level control will close the valve and the end switch will stop the pump.

If multiple boilers are calling for water at the same time, the single pump can satisfy both boilers or the second pump can come on. This depends on how we select the pump flow rate.

What happens if the lead pump cannot keep up and the level continues to drop in the boiler? A second level switch will close, and the standby pump will come on. Since the feed valve is already open, it will pump into the boiler low on water.

This system could have three pumps and two boilers with each pump sized for a single boiler.

Modulating Multiple Boiler Level Controls with Automatic Standby

Large steam boiler plants will often employ a control scheme where the boiler level controls do not operate as on-off controls. They employ modulating controls to maintain a constant level in the boiler. As the level drops at a faster rate, a modulating control valve opens and allows more water.

The piping looks like the boiler diagram above with control valves. Now the control valves are modulating, and the boiler level control provides a variable signal.

The pumps may start on a call for water at any boiler. The number of pumps may match the number of operating boilers. A pump may also be selected with a capacity of multiple boilers. Often, in larger plants, the pump or pumps are simply operating all the time.

This system could employ variable speed controls as long as the boiler signal and drive input are a match. The issue is the requirement for the on-off valves to prevent overfill of boilers. The first cost often outweighs the electrical savings.

R. L. Deppmann will match the Boiler and the Feedwater System

We represent Bryan Boiler, Burnham Commercial, McDonnell & Miller, and Bell & Gossett Domestic Pump. Providing solutions with steam boilers, level controls, and pumping systems matched to the design of the engineer and owner.

Contact us for your project when you work In Northern Ohio and Michigan.