ESP-Systemwize is a powerful tool provided to the industry by Bell & Gossett. As an engineer or designer, you may want to explore the options available for a specific pumping application. B&G provides a variety of choices and you make the selection. Today, let’s explore some of those choices.

ESP-Systemwize is a powerful tool provided to the industry by Bell & Gossett. As an engineer or designer, you may want to explore the options available for a specific pumping application. B&G provides a variety of choices and you make the selection. Today, let’s explore some of those choices.

ESP-Systemwize Pump Product Family or Model, Flow, Head, and Operation

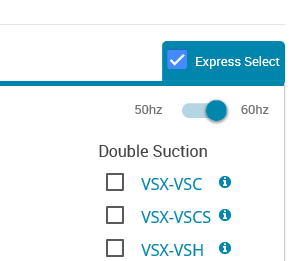

The program defaults to 60 Hz which is what I want in Michigan and Ohio.

The first step in any selection is determining the type of pump you want to use. Some choices are end suction flexible coupled (e1510), double suction (VSX), or inline (e.g., e80-SC). This depends on your client’s needs and to some extent on the capacity required.

In the program, you may select a family of pump types which will give you too many choices. I prefer clicking on express select on the right and then just choosing the model.

Let’s use an example of 650 GPM at 50 feet of head. In my example, the client is a K-12 school and they expect to own the building for a long time, so I will choose an e1510 end suction pump rather than inline. I’ll start by selecting variable speed. If you select constant speed, the printout will be the traditional “Oak Tree” curve you are used to looking at. As we move through this article, I will show you the process in steps. It may appear to be a lot of steps, but they are really very simple and will provide the best results.

STEP 1: Click express select and choose e1510.

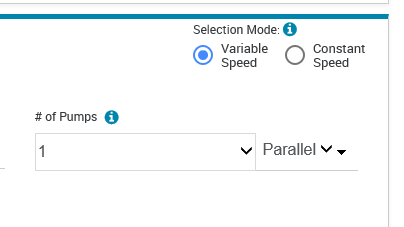

STEP 2: Click variable or constant speed.

STEP 3: Enter 650 GPM of water at 50 feet and enter the control head required for the variable speed system. I’ll select 1 pump in parallel. I may have two pumps, but if one is standby then only one will operate at a time. The other choice is “series” which we rarely see in hydronics and plumbing.

You will notice the control head defaults to 30% of the pump head. The control head is a calculated value based on the system. 30% is a good default for selecting the pump, but the control head will need to be verified at some point. I’ll address this in a later Monday Morning Minute.

STEP 4: Select the motor settings. The default is Non-Overloading Motors, which is a standard specification in the industry. There could be a reason to change it, but for now, let’s leave it as is.

STEP 5: Select the fluid. For this example, we are using water. B&G offers a very usable option when using heat transfer fluids such as Propylene Glycol. You should always adjust this option when pumping fluids other than water. It may have an impact on the horsepower.

STEP 6: Get results.

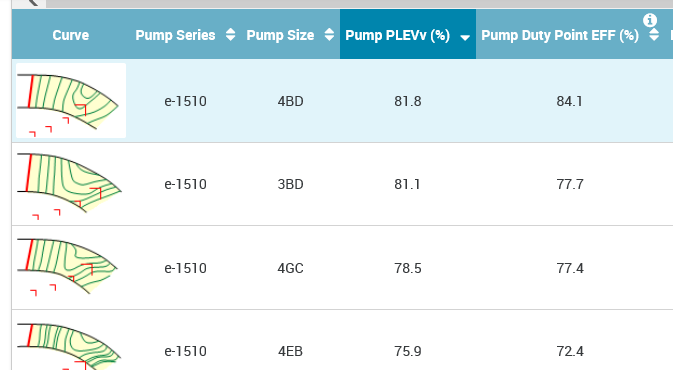

Column Labels in the Pump Selections

Before continuing, let’s look at the information B&G ESP-Systemwize offers to help you make a better decision.

| ITEM | CONTAINS |

|

Curve |

A click here shows you the curve in detail. |

| Pump Series | Useful if you are comparing two series of pumps |

| Pump Size | The exact pump being shown |

| Pump PLEV | This is only shown in variable speed. This is the weighted average efficiency over several points following the control curve. This is a preferred model for comparing true efficiency |

| Pump Duty Point EFF. | The efficiency at the duty point and at the speed shown. |

| Duty Point (BHP) | The horsepower at the design point at the speed shown. |

| Pump Speed (RPM) | The speed of the pump for the impeller size shown at design conditions. |

| Impeller Diameter | The trimmed impeller size at the design conditions. |

| NPSHr | The required net positive suction head |

| Motor HP | The motor nameplate horsepower |

| NOL Power (HP) | This is the most horsepower the pump will experience anywhere on the curve. The non-overloading horsepower. |

| Motor Rated Speed | The nominal speed (3600,1800,1200) |

| Min Shutoff Head | The pump differential head close to zero GPM. This is normally the highest head pressure the pump could add. Used when you are close to the working pressure of system components. |

| Pump and Motor Weight | Total weight for shipping and handling purposes. |

| Pump Flr Space Sq Ft | The area of the pump with a suction diffuser. Could be used with real tight mechanical rooms. |

| Price Index | Relative comparison weighting using the cost of the pump. |

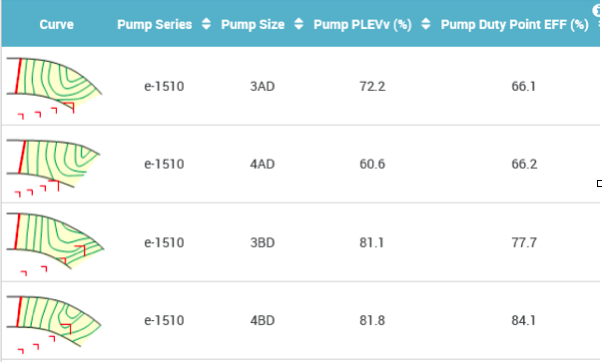

Column Sorting

If you click on the column header, the list will re-sort based on that column. The first screenshot above is sorted on the Part Load Efficiency Value (PLEV). You will notice the order of the pumps is the 4BD, 3BD, 4GC, 4EB.

Right below that is a sorting based on cost or price index. The order has changed to 3AD, 4AD, 3BD, 4BD. It may not be obvious, but the most efficient pump of these four choices turns out to be the most expensive pump. If you want the e1510-4BD and the project is being competitively bid, you may have to add a few notes to the schedule.

Next week the R. L. Deppmann Monday Morning Minute will continue to look at the Bell & Gossett ESP-Systemwize pump selection program and examine the choices offered in a little more detail.