ESP-Systemwize provides a number of pump selection choices. Which pump should I select? Which pump should I fight for in a competitive bidding environment? Today, the R. L. Deppmann Monday Morning Minutes (MMM) offers a simple method to choose the right pump. In the last MMM I explained the basic look and choices offered in the program. I ended with a couple of screenshots of pump selections sorted in different ways. Today we look at a simple way to choose the right pump model.

ESP-Systemwize provides a number of pump selection choices. Which pump should I select? Which pump should I fight for in a competitive bidding environment? Today, the R. L. Deppmann Monday Morning Minutes (MMM) offers a simple method to choose the right pump. In the last MMM I explained the basic look and choices offered in the program. I ended with a couple of screenshots of pump selections sorted in different ways. Today we look at a simple way to choose the right pump model.

Let’s use an example of 650 GPM at 50 feet of head. In my example, the client is a K-12 school and they expect to own the building for a long time so I chose an e1510 end suction pump rather than inline. The pump will be variable speed. I’ll repeat the first 6 steps from last week and then look at the selections.

STEP 1: Click express select and choose e1510.

STEP 2: Click variable speed.

STEP 3: Enter 650 GPM of water at 50 feet.

STEP 4: Select the motor settings (the default is non-overloading).

STEP 5: Select the fluid. For this example, we are using water.

STEP 6: Get results.

Choosing the Best Pump from the Choices

STEP 7: Click and sort on Pump PLEV for variable speed or pump duty point efficiency for constant speed. This will give you the most efficient selections at the top of the list. As a representative for the building owner, we have a bit more due diligence in the following steps.

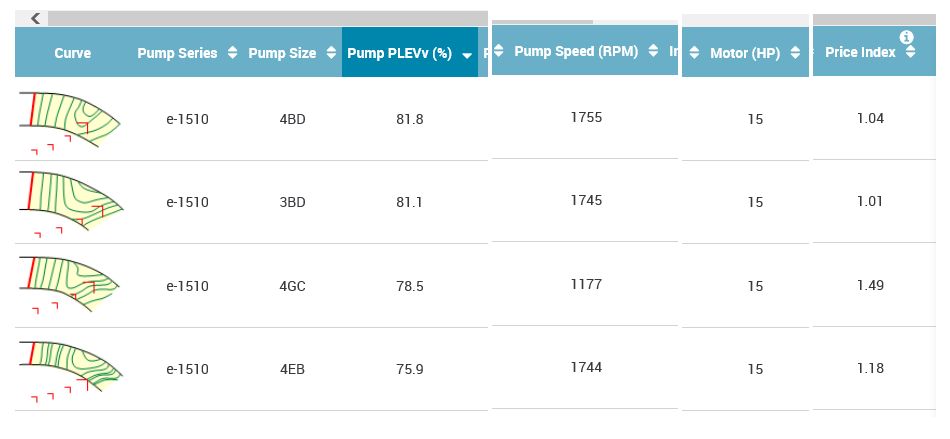

Our choices are shown below. I truncated the list for this article so we can see the four key points to look at:

- PLEV

- Pump Speed

- Point on the Curve

- Cost

I am not looking at NPSHr (net positive suction head required) in this example since I have a closed system. If the suction pressure is low, such as in an open tower system, NPSHr must always be a consideration.

STEP 8: Pump Speed. I want to stay in the 1800 RPM nominal range for noise and life of the motor bearings. I see there are no 3500 RPM selections in these four. There may be one down the list since the 1.0 price index is not shown. The third pump is 1177 or nominal 1200 RPM. In the majority of cases, the cost will eliminate this pump choice.

STEP 9: Check the cost. Look to the far right column using the bar over the list. We see that the most efficient pump will cost about 3% more than the next pump. Will you fight for the 0.7% efficiency? Should we select the second pump? Move to step 10.

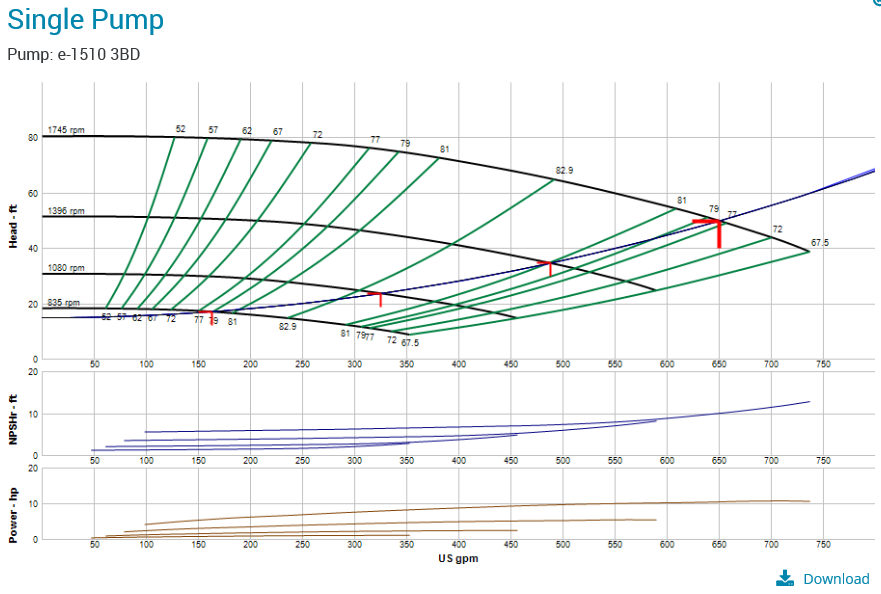

STEP 10: Look at the end of curve. I recommend, as a rule of thumb, not to get closer to the end of curve than 85%. This was shown in a recent Pump Selection Criteria: Maximum Point on the Curve article. Obviously there are times where the rule of thumb may not apply, but in general, I stick in the 85% neighborhood. Let’s look at that second selection.

The point at design is 650 GPM and end of curve (EOC) is about 740 GPM. This exceeds the 85% Norm Hall rule. 85% of 740 GPM is 629 GPM. Close, but you will agree that the selection looks dangerously close to end of curve. I will avoid having this selection added as a competitive choice by restricting selection to 85% as a note on the pump schedule or in the specifications.

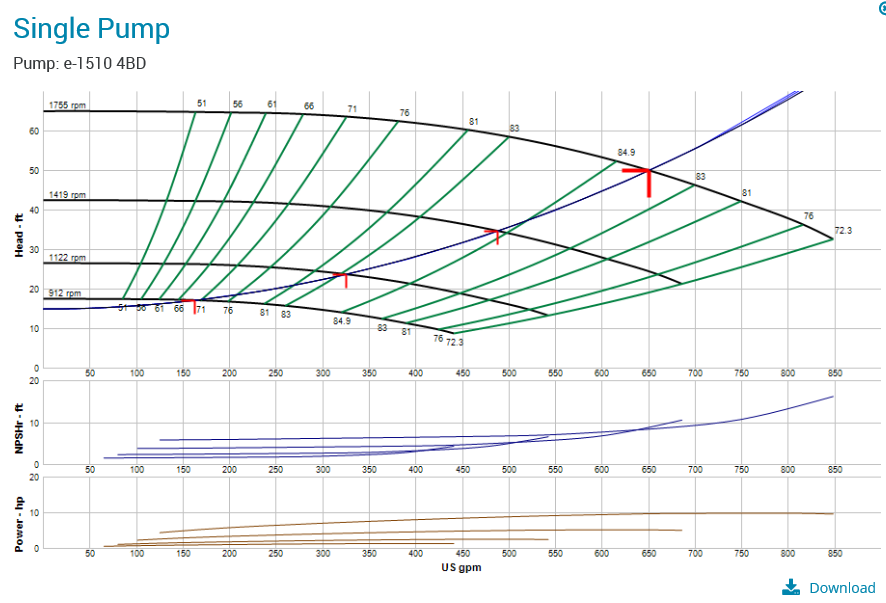

The most efficient pump is only 3% more expensive than the pump selection that exceeds my 85% EOC rule. The curve also looks great. EOC is 850 GPM and 85% of that is 722 GPM. My 650 GPM selection meets the EOC criteria. This is the pump for me.

- Do our competitors evaluate selections?

- Would they ensure your selection is the right choice?

- Would they be able to communicate why?

Important questions to consider.

Next week we will complete this series by reviewing the documentation available to you in the B&G ESP-Systemwize pump selection program.