Not All Plate Heat Exchangers Are Alike!

| Often times when designing a HVAC or Industrial Process system we use unfired heat exchangers. Our choices vary between shell and tube design or plate/frame design. The next few Monday Morning Minutes will offer a glimpse of the variety of plate type exchangers. Today let’s look at three gasketed plate heat exchanger designs and the application of each. |

|

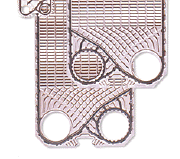

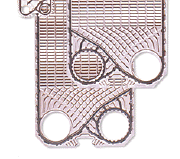

Bell and Gossett SINGLE wall gasket plate heat exchanger series GPX used in chilled water, condenser water, free cooling, geothermal, and process applications when the fluids are compatible with elastomers.Size range from 1″ connections to 18″ connections and flow rates up to 17,900 GPM. |

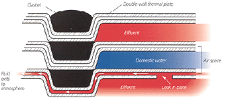

| Bell and Gossett DOUBLE wall gasketed plate heat exchanger series GPX used in domestic water applications and process applications when the fluids are compatible with elastomers and code or safety requires a means to prevent cross contamination in the event of a leak. Make sure your specification includes an air space and a leak path to atmosphere. |

|

|

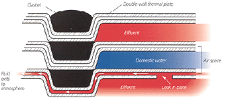

Bell and Gossett FREE FLOW plate heat exchanger series GPX used in process applications when clog-resistant design is important. This design features minimum or no metal-to-metal contact points to reduce the opportunity for particles to catch on the plates. |

Next week we look at brazed plate exchangers.

Disclaimer: R. L. Deppmann and it’s affiliates can not be held liable for issues caused by use of the information on this page. While the information comes from many years of experience and can be a valuable tool, it may not take into account special circumstances in your system and we therefore can not take responsibility for actions that result from this information. Please feel free to contact us if you do have any questions.

Archives – Click here for Past Articles