Not All Plate Heat Exchangers Are Gasketed!

Last week we introduced three varieties of Bell and Gossett gasketed plate heat exchangers. Today, we look at three types of brazed plate heat exchangers. A brazed plate exchanger is a plate exchanger without gaskets or rolled joints. The plates are brazed so there are no elastomers. Brazed heat exchangers are generally available in smaller sizes than our B&G GPX plate/frame exchangers.

|

Bell and Gossett BP brazed plate heat exchangers use 316L plates and copper braze material. Available with UL label and with recommended ASME code stamp. Design pressures to 435 PSIG with design temperature of -310°F to 450°F.

Excellent for clean liquid applications in Industrial cooling, hydronic heating and cooling, radiant, and snow melt.

Flow rates to 800 GPM and 350 sq.ft. surface area. |

|

| Series BP-LP is a “light” version of the BP with 150 PSIG design, low pressure drop. Ideal for residential and low flow commercial applications. |

|

|

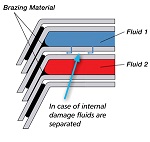

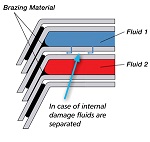

Series BPDW “TRUE” double wall model for domestic water applications using solar, boiler, refrigerants, and oils.

Meets Michigan and Ohio plumbing codes. |

|

| Series BPN nickel brazed heat exchanger for industrial applications, RO water, DI water, Biodiesel, and other applications where copper cannot be used. |

|

|

Bell and Gossett Brazed Plate exchangers are available with a variety of connection types and mounting tabs to help reduce installation costs. |

Next week we look at brazed plate heat exchangers.

|

|

Disclaimer: R. L. Deppmann and it’s affiliates can not be held liable for issues caused by use of the information on this page. While the information comes from many years of experience and can be a valuable tool, it may not take into account special circumstances in your system and we therefore can not take responsibility for actions that result from this information. Please feel free to contact us if you do have any questions.

Archives – Click here for Past Articles