Temperature is important in heating and cooling systems. Today’s Building Management Systems (BMS) may monitor key areas of interest in the hydronic piping systems. Many building owners still rely on thermometers for a quick confirmation and as a troubleshooting instrument. Let’s look at thermometers and wells in this week’s R L Deppmann Monday Morning Minutes.

Temperature is important in heating and cooling systems. Today’s Building Management Systems (BMS) may monitor key areas of interest in the hydronic piping systems. Many building owners still rely on thermometers for a quick confirmation and as a troubleshooting instrument. Let’s look at thermometers and wells in this week’s R L Deppmann Monday Morning Minutes.

Thermometers in hydronic and plumbing systems come in a variety of styles but most specifications focus on a single type. I like to know what I am choosing but also what I am not choosing, so let’s start with a brief description.

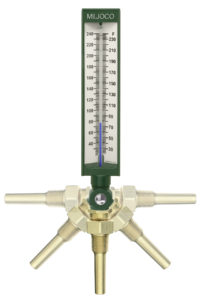

Liquid in Glass Industrial Thermometers

The standard in the industry is the vertical column “liquid in glass” 9” thermometers with an adjustable angle and some fluid that is green, red, or blue in a tube. If you are old enough to remember John F. Kennedy as president, these were called mercury thermometers. These thermometers have been mercury free for a long long time and instead have a non-toxic liquid spirit that moved up and down in the tube as the temperature changes.

The accuracy is stated as ±1 division. The Miljoco SX935 series with a range of 30°F to 240°F has a 2 degree division so the accuracy is 2°F. The advantage of these thermometers is they are adjustable angle which directs the visual display if the pipe is eight feet up and you are only five feet up. They are available without adjustable angle but unless it is at reading height, it’s not worth the few dollars you save. They can be hard to read depending on where you stand and the light available. Your eyes may contribute to the inaccuracy. They are also the least expensive thermometer of the three I will review.

Bi-Metal Thermometers

The next thermometer is the adjustable angle “bi-metal” thermometer. These are stainless steel and hermetically sealed. They have two different metals sealed together and one expands at a different rate than the other. The advantage to these are that they can rotate or adjust 360° and have a flat face with a dial. They are very easy to read even if they are up in the air. The accuracy is ±1% of scale so in a 0 – 250°F, the accuracy is ±2.5°F.

Bi-metal thermometers come in various round dial sizes but the only one that makes sense is the 5” dial. The bigger the dial, the easier to read. Go big or go home! (Smiling) The down side is the price. They will cost about 50% more than the liquid in glass industrial thermometers. If you think $60.00 for the 9” industrial thermometer, the bi-metal will be about $90.00. Pricing will vary with every possible variable but this is close enough to give you the range.

Vapor Tension Thermometer

These thermometers normally are remote mounted. They have a dial like the bi-metal but also have a capillary tube with a fluid that expands with temperature. We find these on freezer cases or items where the thermometer accuracy would be affected by the ambient conditions. Not used too often in our world and they cost at least twice that of the 9” industrial thermometer.

Installation and Accuracy of Thermometers

The largest inaccuracy of a thermometer is not the thermometer itself but the installation. In order to accurately read the liquid temperature, the thermometer must be installed well into the fluid. Putting a thermometer with a 3-1/2” stem into a 12” pipe may not be representative of the liquid temperature.

Getting the thermometer stem into the flow of water is also critical. Thermometer installations on larger steel pipe installations are easy. Put a weld-o-let on the side of the pipe and be done with it. What about smaller pipe? You may think it is easier but let’s look at dimensions.

Suppose you have 1-1/4” copper pipe. A 9” thermometer may have a 3-1/2” stem. Here the stem will not fit into the smaller pipe. If the tee is extended to get the stem to fit, the stem will not be in the will not be into the flow of the water and accuracy will be affected. So we would recommend installation at a turn using a tee instead of an elbow to install the thermometer.

A copper tee with FPT adaptor is starting to add up in length and most of the stem will not be in the water flow. In addition, the ¾” well takes up a lot of area in a small pipe. It may seem odd but the small pipe may need a larger stem because of the installation and we address this in our specifications.

Insertion Wells for Thermometers

Every thermometer should have a well. It becomes a real issue if we have to drain the system to replace a broken thermometer. Wells are normally brass. Plumbing system thermometers should have a low lead well.

Next week we will wrap it all up with pressure and temperature test plugs and a suggested specification for pressure gauges, gauge trim, thermometers and PT plugs. Check it out next week in the R L Deppmann Monday Morning Minutes.