Indirect steam water heaters for domestic water use are often the solution engineers will choose in institutional or industrial buildings. They require no venting. They can take up less space. The condensate handling equipment may exist nearby for the hydronic heating system. When selecting these heaters, the R. L. Deppmann engineering rep will ask about steam pressure and suggest the use of low-pressure steam. Why?

Indirect steam water heaters for domestic water use are often the solution engineers will choose in institutional or industrial buildings. They require no venting. They can take up less space. The condensate handling equipment may exist nearby for the hydronic heating system. When selecting these heaters, the R. L. Deppmann engineering rep will ask about steam pressure and suggest the use of low-pressure steam. Why?

Low Pressure vs. High Pressure Steam

It is always smart to start with the definitions. Low pressure steam is clearly defined as saturated steam under 15 PSIG. The ASHRAE HVAC Systems handbook, section 11.2, defines high pressure steam as anything over 15 PSIG. There are numerous sub-categories of high-pressure steam, but we will limit the terms to low pressure and high pressure for this blog. In this article, I would also want you to consider dropping that low pressure steam to the lowest pressure you can. After reading this, you will understand that 5 PSIG is much better for most hydronic heat exchanger applications and even more suitable for domestic water heaters.

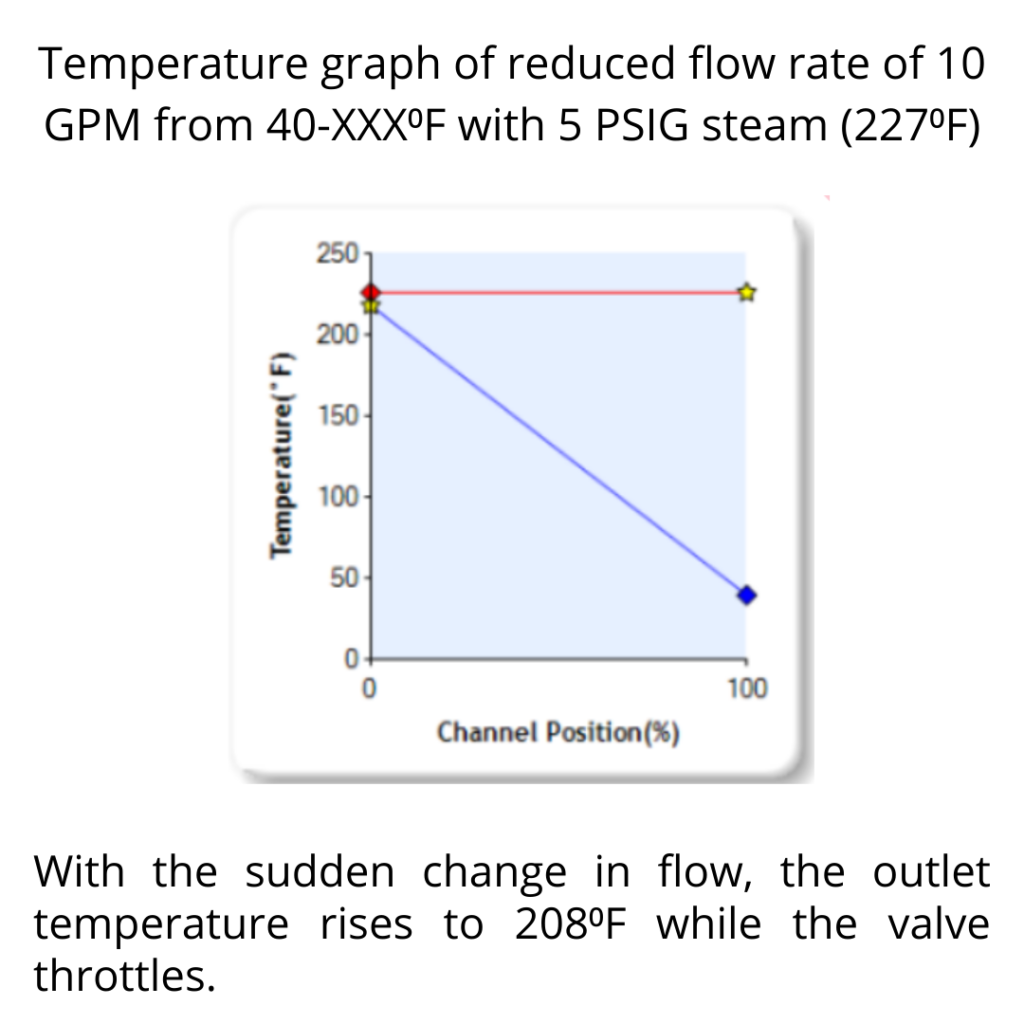

I’ll use, as an example, comparisons between 5 PSIG and 50 PSIG steam. 5 PSIG steam has a saturation temperature of 227⁰F. 50 PSIG steam has a saturation temperature of 298⁰F.

Condensate Return Issues

The first issue I have with using high pressure steam are the problems created at the condensate return system. Once the steam is condensed in the heat exchanger, the condensate is normally discharged as water or condensate at the saturation temperature of the steam. From there, the condensate normally flows by gravity to a vented condensate return unit serving many connected steam items.

If low pressure steam is supplied to the heater, there is a good chance the heat will dissipate in the return and the temperature will drop below 212⁰F before it gets to the receiver. There will be no flashing of the condensate. This is not the case with high pressure steam.

The example mentioned above has a saturation temperature of 227⁰F when using 5 PSIG steam. Assume the water heater was only a few feet from the condensate unit. The Hoffman steam calculator in our Design and Selector tools website shows the condensate would only flash 1.5% as the temperature dropped to 212⁰F. There is little concern or issue in the condensate system as long we don’t lift out of the water heater.

The 50 PSIG steam would flash 600% more of the condensate into steam. This would require a flash tank or a dedicated non- vented condensate unit to avoid issues.

There are some indirect steam water heaters that sub-cool the condensate. The Aerco B+II water heater is one example. Performing with 90%-99% thermal efficiency, the unique 2-pass helical coil heat exchanger design of these single wall heaters is self-descaling and produces sub-cooled condensate (<160°F) to preserve condensate return pump life.

Condensate handling is a big reason we suggest low pressure steam in hydronic heat exchangers. It is also important in domestic water heaters but there is an even more compelling reason.

Changing Loads and the BTUH Formula

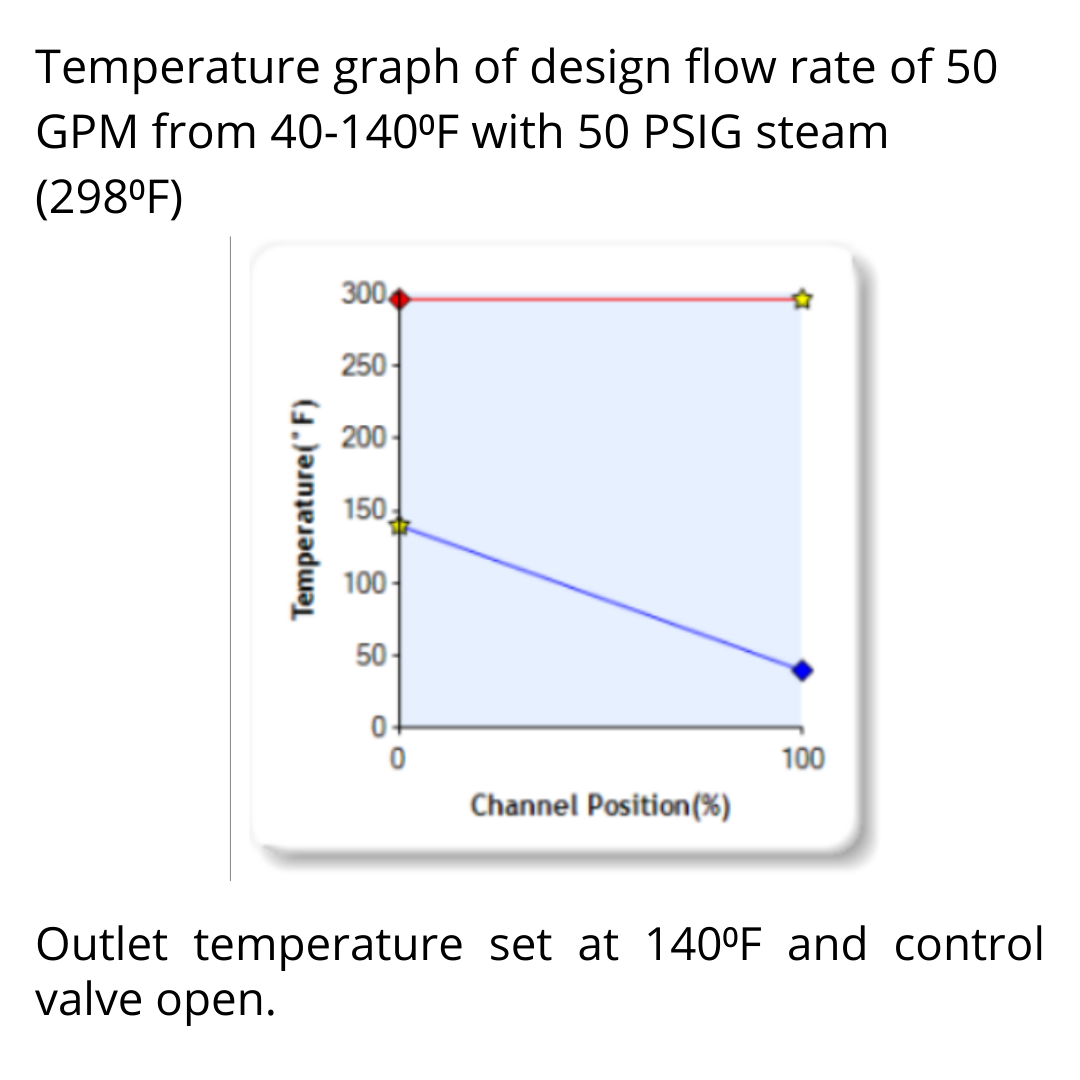

We are all familiar with the BTUH formula to arrive at the square foot heating surface required.

Where Q is the BTUH required or used; A is the area of the exchanger; U is the overall heat transfer coefficient; and LMTD is the log mean temperature difference between the steam temperature and the water temperature.

Once the water heater is sized, purchased, and installed we know that “A” is fixed. What happens as the load changes? For example, flow rate is 50% of the design flow rate and the outlet temperature needs to remain at 140⁰F, the load is now 50% of the design but the area is fixed. The heater is oversized for this condition. The steam, inlet water, and outlet water temperatures remain the same. The LMTD required, based on the set point, remains the same. The control valve throttles the steam entering the heater. This drops the “U” value. The valve continues to throttle until the U drops in half.

This is a nice smooth transition in a hydronic heating system. It would be highly unlikely to see a load change that great in seconds or even minutes. This is not the case in many domestic water systems.

The Issue of Varying Loads and High-Pressure Steam

What happens if the load changes abruptly before the control valve can catch up? If the valve cannot keep up, the set point will rise until the valve throttles. The LMTD will not remain the same because the outlet temperature will overshoot. How much of an overshoot could occur? A lot more with high pressure steam than low pressure steam.

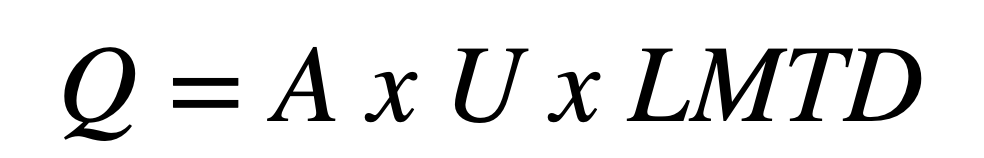

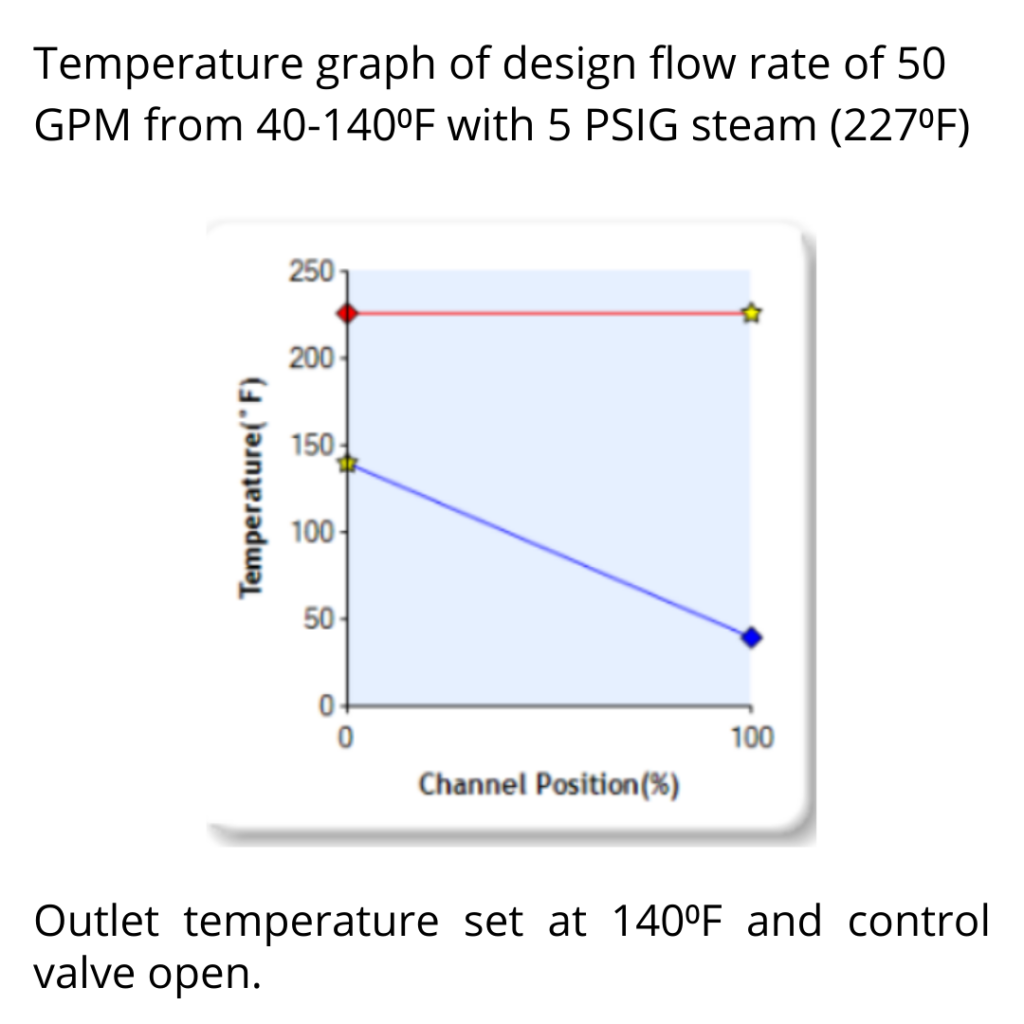

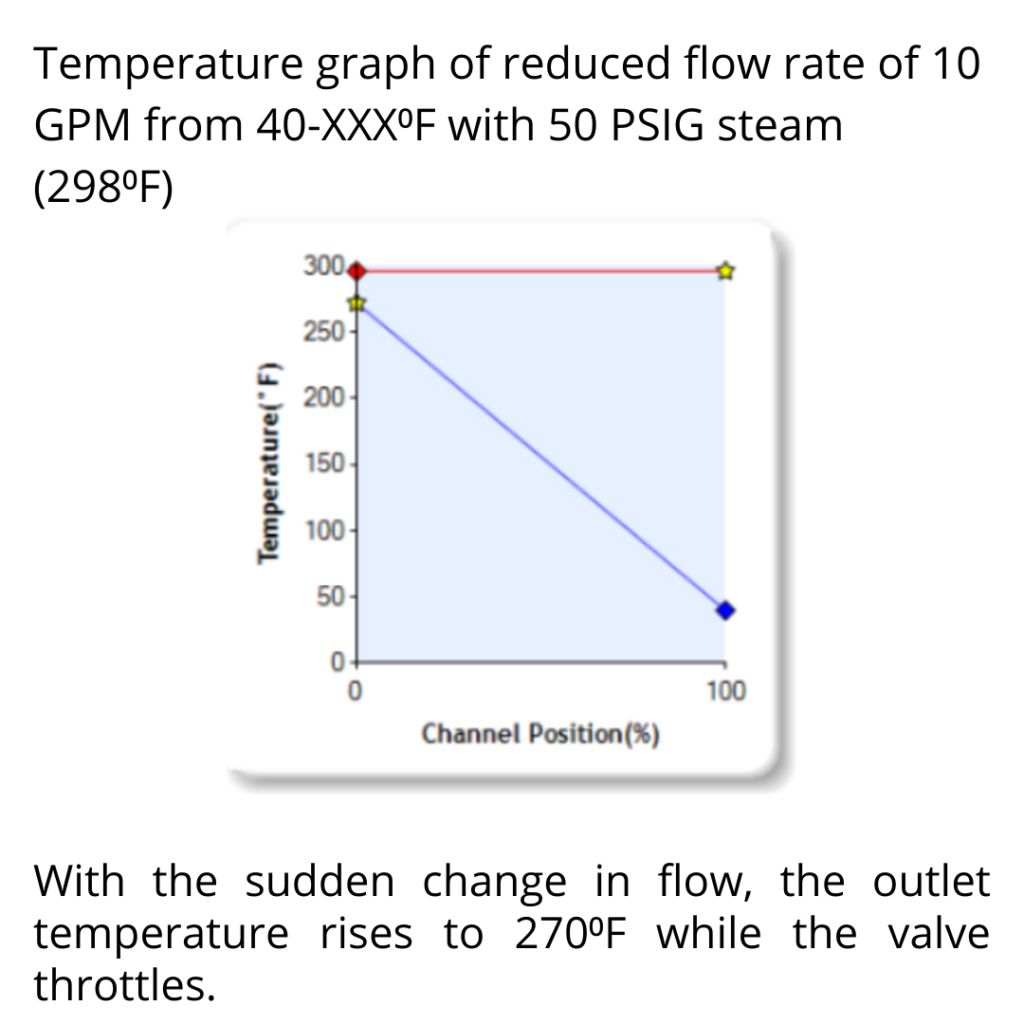

Look at the following sets of temperature charts. I assumed the flow rate changed from design to 20% of design instantaneously. The steam valve was wide open and now it is called on to throttle very quickly, maybe instantaneously.

Low Pressure Supply

The temperature in the instantaneous exchanger will rise to 208⁰F in a matter of a few seconds.

High Pressure Supply

The temperature in the instantaneous exchanger will rise to 270⁰F in a matter of a few seconds.

We would recommend the dual high limit controls also called solenoid safety system. For these reasons, we would recommend putting a pressure reducing valve in and reduce that steam pressure.

When is Higher Pressure Steam Acceptable?

Instantaneous indirect steam water heaters have a great deal of safety controls. If the load will not drop by 50% instantaneously, you may be comfortable with higher pressure. If the water heater has a buffer storage to temper the overshoot, you may be comfortable with higher pressures. If the volume in the piping system is large and the distance to the first fixture is long, you may be comfortable with higher pressures. If you are not sure, remember, it is hard to fight mother nature and that is why we suggest low pressure steam.

Next week, the R. L. Deppmann Monday Morning Minutes will introduce a couple of new water heater tools to help you make a great decision for your client, the owner of the building.