One of our many new employees asked a valid question about cast iron condensate unit pump construction. The employee has worked in the HVAC plumbing industry trades and always wondered why condensate pump inlet flanges are often rectangular instead of standard round flanges. It took me a minute or two, since, during 45 years in the steam business, no one ever asked the question. The answer to this is critical to the proper operation and long life of condensate equipment.

One of our many new employees asked a valid question about cast iron condensate unit pump construction. The employee has worked in the HVAC plumbing industry trades and always wondered why condensate pump inlet flanges are often rectangular instead of standard round flanges. It took me a minute or two, since, during 45 years in the steam business, no one ever asked the question. The answer to this is critical to the proper operation and long life of condensate equipment.

Contest with Prizes After Reading This and Checking the Links – See the Last Section

Rectangular Pump Suction or Inlet Flanges

If you glance at the photo above, you notice the suction flange is rectangular and very low in the casting. Also, notice the packaged unit pump is mounted to the receiver at the lowest point in the casting. This is expensive to cast and expensive to inventory compared with standard ANSI flanges. Why are they like this?

Steam Condensate Return Temperature in Commercial Systems

The heating system steam passes through a coil, heat exchanger, or terminal unit and gives up its latent heat. It turns from vapor to liquid. That liquid or condensate is very close to the saturation temperature that the steam was at when it entered the coil. There may be some subcooling or cooling in the pipe as the condensate loses temperature through the pipe insulation.

The water may be close to or a small percentage below the boiling point when it reaches the vented condensate receiver. The available NPSH at the pump suction is often very limited.

Our Friend or Foe – NPSH

NPSH or net positive suction head is the amount of absolute pressure required or available at the inlet of a pump to keep the liquid from turning into vapor. Or said another way, the absolute pressure to keep water from becoming steam. If you need to review this important pump requirement, visit our R. L. Deppmann Monday Morning Minutes article, Net Positive Suction Head (NPSH).

So, the NPSH available is our friend when it is greater than the NPSH required. It becomes our foe when it is too close or below that required by the pump.

The elevation of the water above the pump becomes important in condensate applications. Inches may make the difference between good operation and troublesome service calls. We want as much elevation as we can get.

Most Condensate Return Pipes are Low

If you’ve been around mechanical rooms with condensate pipes, you know the pipes are very low to the ground. You should not raise the condensate pipe to get into the receiver, so we want a low inlet. Maybe only 14” or 20” above the ground.

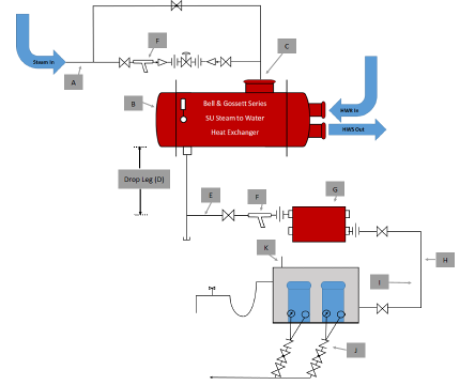

So NPSH wants higher elevation in the tank and the low condensate pipe location wants a low return level. In between those two levels are floats for pump on and pump off levels. There is also room for a standby pump float and even a high-level alarm float. That’s a lot of things going on in a few inches. Look at the following sketch from our blog Understanding Steam and Steam Heat Exchangers.

If this was a 36-gallon receiver, the bottom of the inlet pipe would be 11.5” above the floor. The return unit is normally on a housekeeping pad of a couple of inches. If the maximum water level is 2” below the inlet and you used a 3” ANSI flange at the pump, there would only be 2-3/4” to store water and activate all the floats. The square flange gives us almost double that. The result is more storage and more NPSH available.

Non-Turbulent Flow into the Pump

The other concern is the flow pattern into the pump. If you design hydronic systems, you know that pumps need 5 pipe diameters of straight pipe or a suction diffuser straightening vane fitting. More information on this topic is available at our blog Hydronic Pump Piping and Trim: The Pump Suction.

With a floor mounted condensate unit there is no room for straight pipe. The rectangular pump inlet coupled with the rectangular cast iron receiver allows for smoother flow than a round pipe. This also reduces the chance of cavitation due to low NPSH available and pressure differences at the impeller.

Conclusions

With the tight, floor mounted, condensate return units, the square flange serves to increase the static head pressure on the pump and allow for smooth flow patterns into the impeller. Elevated condensate return units do not have these challenges so different styles of pumps may be used.

Contest: Think You Know NPSH? Can You Select the Right Pump?

You have a system with 204⁰F condensate from a PVI domestic water heater and a B&G SU heat exchanger. Given the flow rate and discharge pressure required, which floor mounted condensate pump would you accept?

We will select 10 names* from the correct responses and send them the prize shown below. The quiz is in this link: MMM 08-09-21 Quiz challenge.

* Although we encourage the Xylem employees and B&G representatives to take the quiz. They will not be eligible for the prize drawing.