What can be simpler than pumping water from an open or atmospheric tank into another tank or system? What seems simple to many opens a complete list of questions to the engineer who is familiar with pump selection and operation. This R. L. Deppmann Monday Morning Minute looks at the information needed to select and control the pump.

What can be simpler than pumping water from an open or atmospheric tank into another tank or system? What seems simple to many opens a complete list of questions to the engineer who is familiar with pump selection and operation. This R. L. Deppmann Monday Morning Minute looks at the information needed to select and control the pump.

Pump Selection Flow and Head and Pump Choice

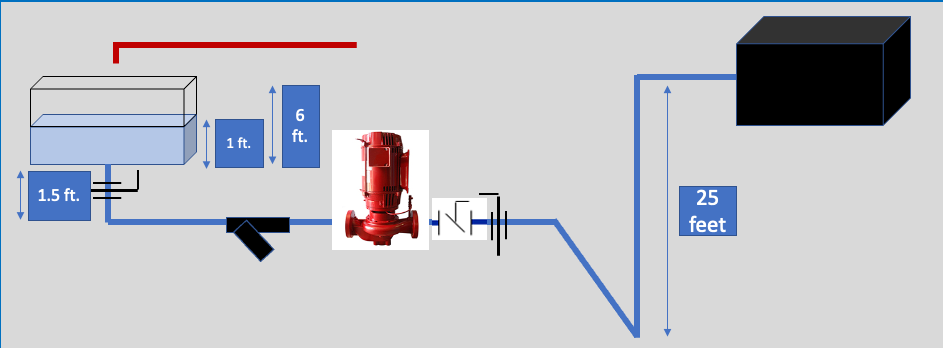

The obvious first step in any pump selection is the flow and head required. What is the design flow rate of the “black box,” or system represented in the sketch above? Let’s say the system is a process plant with a requirement of 150 GPM of water. We know the design flow rate.

The next step is pump head. We select the pipe size and determine the friction loss of the piping, fittings, and valves. We could use the Bell & Gossett System Syzer for that. Let’s say that the friction loss is 32 feet. Next, we need the elevation of the system. In the example system, the discharge elevation is 25 feet. The pump suction elevation is also simple. The elevation to the pump suction is the height of the water in the open tank at its lowest possible level. In the example, this is 1 foot in the tank and 1.5 feet of outlet pipe elevation for a total of 2.5 feet. The pump elevation required, or lift is 25-2.5= 22.5 feet. The pump head, so far, is 22.5 feet of lift plus 32 feet of friction or 54.5 feet total.

We need one more thing. The pressure required to the black box of the system. In this real-life example, the plant manager indicated the requirement at the process loop header of 50 PSIG (115 feet). Just as in a domestic water pressure booster the pressure must be added to the atmospheric fill pump unless there is a pump in the process system already. We asked and there is no such pump. The pump head is 115 + 54.5 =169.5 feet. Adding a 10% safety factor makes the capacity required 150 GPM of water at 187 feet of TDH.

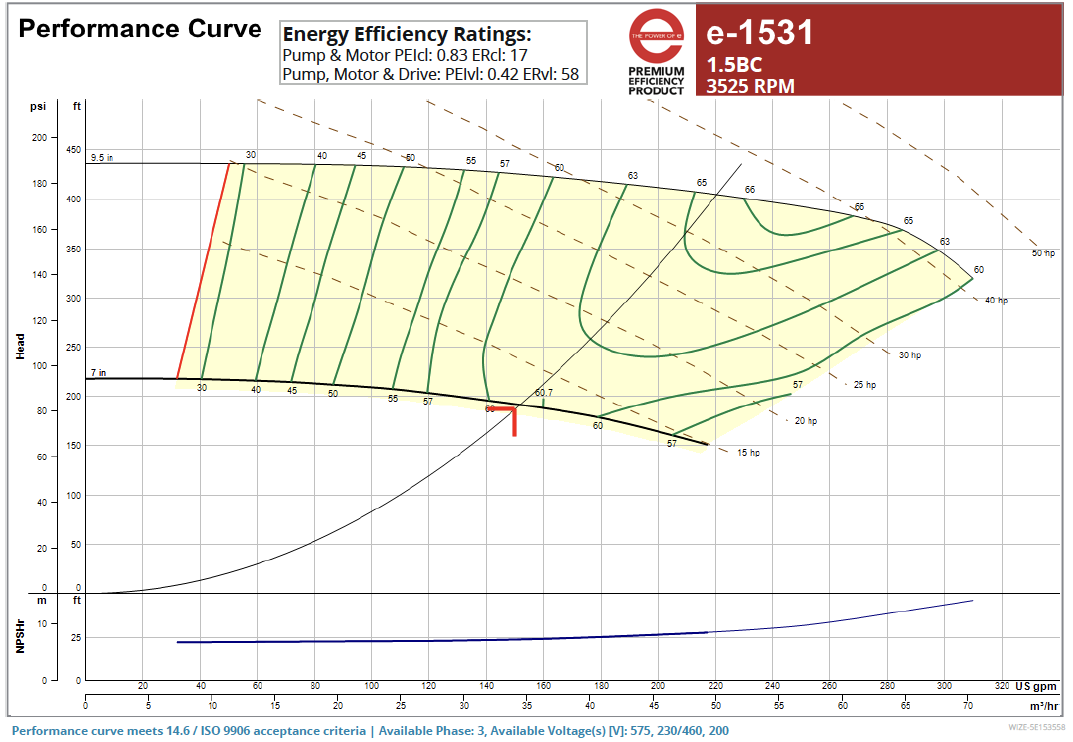

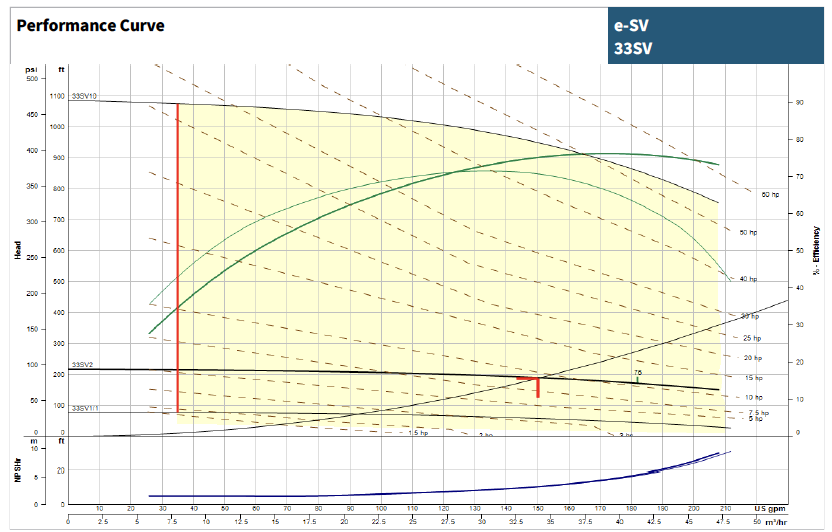

Here are two different pump selections that meet the required capacities.

Both pumps will use a 15 HP motor to be non-overloading. The first curve is an end suction B&G e1531 close coupled pump. The second is a floor-mounted B&G eSV inline multistage pump. The first pump is cast iron while the second pump is stainless fitted and available in all wetted parts of 316SS. The second pump would be preferable since the system is open and the tank is constantly refilled with fresh water. If the water was RO, then the stainless is again preferred. Another advantage of the second pump is the NPSH.

NPSH or net positive suction head is not really a big concern since the water is at room temperature or colder. That said, the 25 feet required for the first pump could become an issue if the strainer starts to plug up. I am not sure why the strainer is even needed. The water is clean and filled from the city system. I would eliminate the strainer.

Pump Control – Constant or Variable Speed

|

The suction side of the pump has an almost constant pressure. The difference between full and minimum levels is only a few feet. If the owner always requires 50 PSIG at the inlet to the system and there is always a flow of 150 GPM, there is no variation and no need to put a variable frequency drive on the pump.

We had a discussion with the plant manager and found that the system was a series of 10 washdown processes for the process. There will be sometimes when all will be on but other times when only one washdown system is being used. The plant manager said the 50 PSIG at the system header inlet is needed whether one or ten machine washdown is active. If we put a drive on the pump, it will save some energy, but it also gives the owner something else. The shutoff head of the second pump is over 200 feet. That means the system header will see over 80 PSIG when operating at one or two washdowns. The owner was concerned about that. We suggested a drive to avoid the issue. The great news is that the pump selected is available with a motor-mounted Hydrovar VFD which is pre-mounted and wired. It comes with a fused disconnect mounted and wired. The drive is pre-programmed for a single pump operation and the rotation is confirmed. A nice complete smart pump. |

So, we have a B&G eSV small floor-mounted inline multistage pump with a 15 HP motor and a motor-mounted pre-programmed drive with disconnect. Next week, we will look at control options and installation tips for pumping from an atmospheric tank.