Chilled water condensers are normally operated as constant-flow devices and the pumps serving them are constant-speed. Why would you ever use a variable-speed drive for a pump in this application? This week we show you a couple of reasons.

Automatic Differential Pressure Control

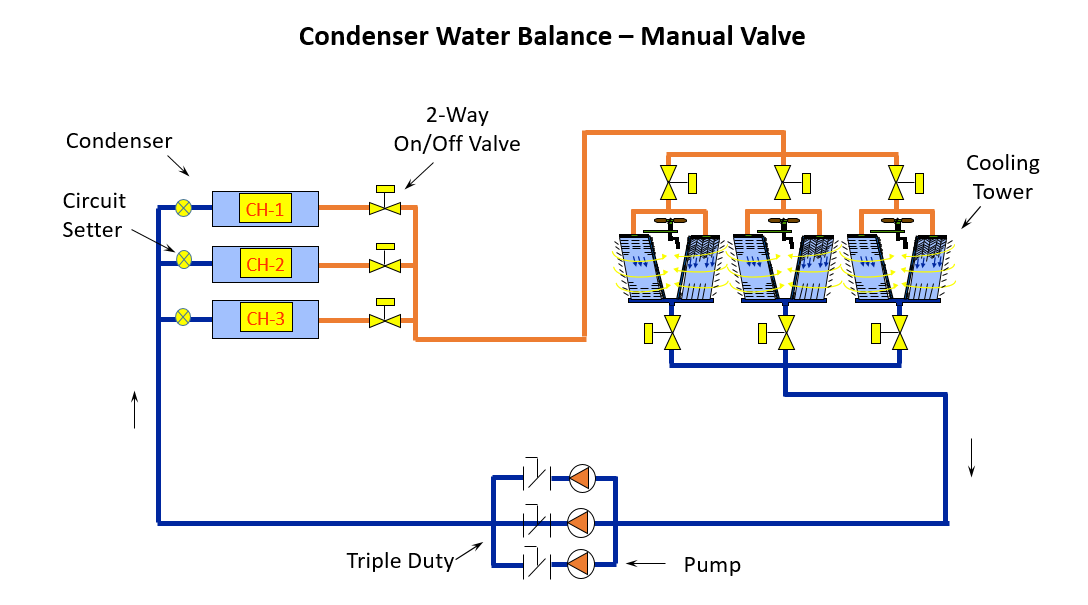

In part 2 of this series we used a variable-speed drive with contact closure points to operate at full speed when all condensers are active and reduced speed when only one or two of the condensers are operating. What if we add a pressure differential sensor across the system? Is there any advantage to automation? The example used in part 2 is 800 GPM per condenser for a total of 1600 GPM with the third condenser as standby. The tower elevation or lift is 10 feet, the condenser with the two-way valve and balance valve has 20 feet of pressure drop, and the common piping with any safety factor has 30 feet of pressure drop.

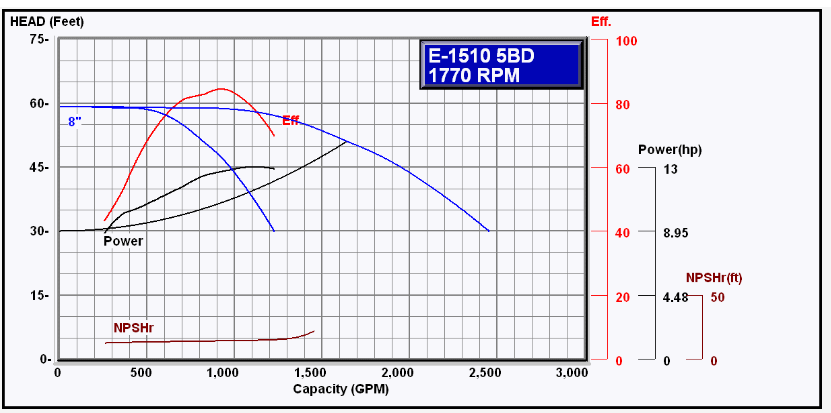

The pumps selected were two pumps in parallel with a capacity each of 800 GPM at 50 feet head with a third pump as standby. In parallel pumping, the single pump operation is at the intersection of the single pump curve and the system curve. We showed last week that the flow rate when one pump was operating with one condenser was greater than the 800 GPM design and, in this example, great enough to cause velocity issues in the condenser.

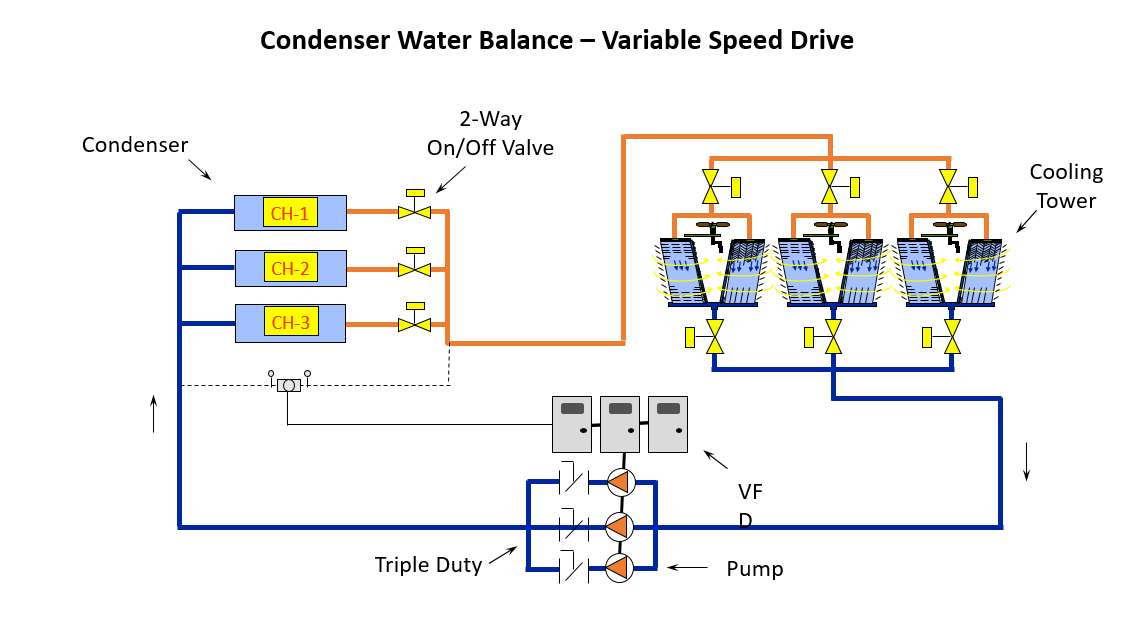

Let’s start by assuming each condenser is identical. If we add variable speed drives, VFD, to the pumps and add a differential sensor, DP, sensor across the headers, what might we gain? The representation below shows the DP sensor across the condenser header. Since the condensers are all equal flow, the two-way valves are on-off, and the balance valves adjust for piping differences, a single sensor may be used with a single set point.

Additional Benefits of Automatic Differential Pressure Control

Part 2 of this series addressed the advantages of using a VFD to avoid the excessive flow rate through condensers. There is an additional advantage to using automatic DP control which may be a tremendous benefit to your end user client. All pumps are over-headed. We add a safety factor to pump head calculations, and in tower systems we may add some for strainers getting plugged. We may even use a lower roughness coefficient like C=100 in the Hazen-Williams formula to account for scaling as the pipe ages.

We know strainers will foul in an open system, and the end user is faced with the job of checking the strainers often. If your design uses a DP sensor, there is little question that the operation at 100% design flow will result in pumps operating at less than nameplate RPM and that will save operating costs. Additionally, as the strainers clog up, the speed will increase to maintain the DP setting at the condensers. The more clogging, the higher the pump will speed up.

You could set a building management system alarm if the pumps ever get to full speed or a speed of your choice. That alarm would indicate the time to clean the strainers out. No need to use valuable maintenance time to check strainers anymore. What is that worth to your end user?

Recommended DP Strainer

Speaking of strainers and pressure drop, how would you like to use a strainer that has 50% less pressure drop without a cost premium? Metraflex has a model LPD Y strainer you may want to look at. In our example, an 8” strainer at 800 GPM design saves 60% of the pressure drop compared with traditional old school designs. And the pricing is competitive.

One final note: Using variable frequency drives in condenser water pumping systems is not a free pass to grossly oversize pump head. We highly recommend that a detailed pump head analysis be documented with a conservative value included to accommodate a strainer fouling and aging pipe.

Next week, we’ll look at the use of unequal condensers in this application.