The last several R. L. Deppmann Monday Morning Minutes articles focused on steam and condensate handling. Condensate flashes into steam in the return lines after the steam traps. When the steam pressure exceeds 15 PSIG and is defined as medium or high pressure, flash tanks are used to control where flashing occurs. The flash tank provides a “bubble” in the pipe with enough volume to allow the higher temperature condensate to flash into lower pressure steam.

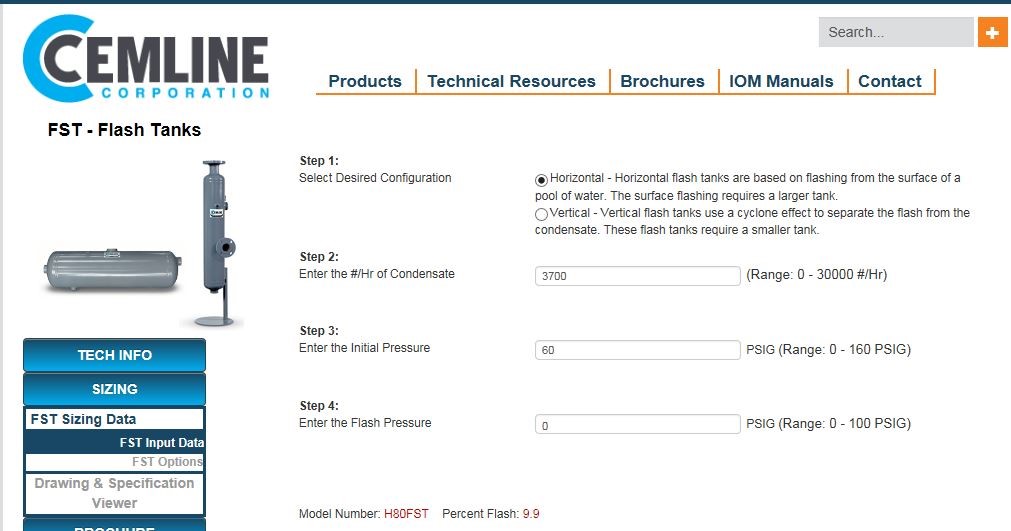

In general, there are two types of steam flash tanks used in HVAC systems: horizontal and vertical. Flash tank outlets may be vented to atmosphere or may be isolated with a valve to capture the steam and reuse it in a lower pressure application. Let’s look at the two types of tanks and we will use an example of a system with 3700 PPH of condensate from a 60 PSIG steam system and a flash tank sized to bring the pressure down to 0 PSIG.

In general, there are two types of steam flash tanks used in HVAC systems: horizontal and vertical. Flash tank outlets may be vented to atmosphere or may be isolated with a valve to capture the steam and reuse it in a lower pressure application. Let’s look at the two types of tanks and we will use an example of a system with 3700 PPH of condensate from a 60 PSIG steam system and a flash tank sized to bring the pressure down to 0 PSIG.

Cemline Corporation, an American manufacturer of ASME flash tanks, is represented by R. L. Deppmann Company in Michigan and Northern Ohio. Their website offers a sizing program to select a model and obtain drawings when you know the capacity in PPH, the initial pressure, and the flash pressure. I will use this program and the associated drawing printouts as examples in this brief series of articles.

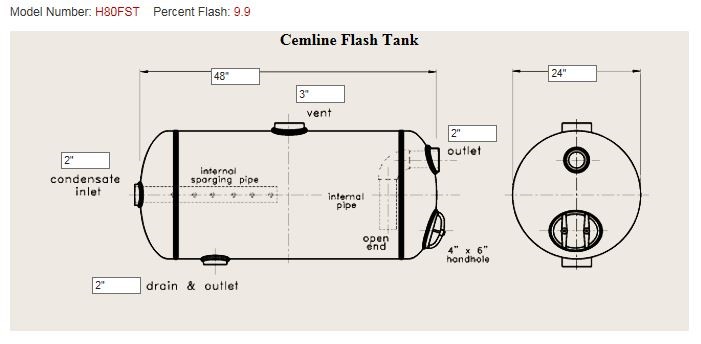

Horizontal Condensate Flash Tanks

Horizontal flash tanks are more often the traditional style. They are designed and sized to give a required disengaging area. This area is the length times diameter of a horizontal tank and is coupled with the tank volume above the water level to vent dry flash steam. Dry flash steam is steam that is not carrying excessive amounts of condensate with the flash steam. The more pounds per hour (PPH) of condensate entering, the larger the tank. The higher the steam pressure, and therefore the temperature of the condensate, the larger the tank. The lower the flash pressure and corresponding saturation temperature, the larger the tank.

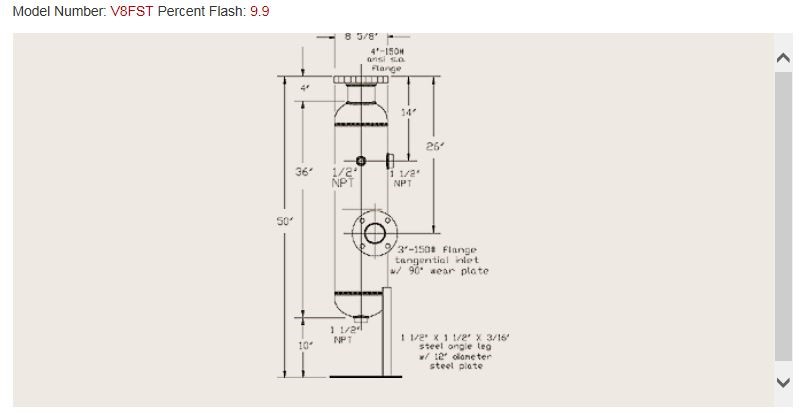

Vertical Condensate Flash Tanks

Vertical flash tanks use a different principle. Vertical flash tanks use tangential openings and “spin” the condensate around the diameter of the tank. The flash steam is lighter than the water, so it moves to the inside and is vented up while the condensate moves down. If this sounds familiar, it is. Those of you who design hydronic systems are aware of this difference. The Bell and Gossett Rolairtrol® air separators use tangential openings and centrifugal force to actively remove air from the water. Tank size for size, this is a more efficient device. Flash tanks are similar to this science resulting in vertical tanks that are more efficient. In general vertical tanks are smaller than horizontal tanks.

The Cemline program automatically selects the correct tank size and opening sizes required AND provides you with a CAD ready drawing. If you would like to sign up for the Cemline sizing program, just visit the product portion of our website for the link.

Check out our similar content: Medium and High Pressure Steam Vented Flash Tank Trim