There are many types of air vents in hydronic heating and cooling HVAC systems. It is not unusual to see an engineered set of drawings with a manual and automatic vent detail. What is unusual, in direction to the contractor of which vent to use is which location. Today’s R. L. Deppmann Monday Morning Minutes will offer a suggestion.

There are many types of air vents in hydronic heating and cooling HVAC systems. It is not unusual to see an engineered set of drawings with a manual and automatic vent detail. What is unusual, in direction to the contractor of which vent to use is which location. Today’s R. L. Deppmann Monday Morning Minutes will offer a suggestion.

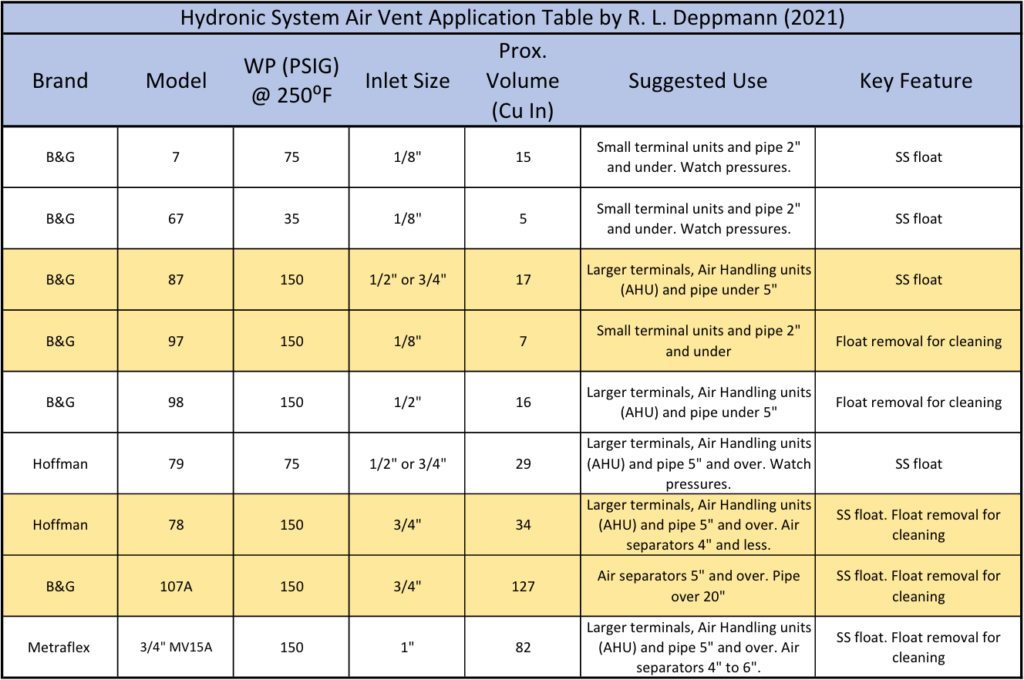

Bell & Gossett, Hoffman Specialty, and Metraflex offer a variety of air vents. Which vent should I use where in commercial and institutional larger HVAC systems? At the end of this blog, I have a suggested schedule for vents. Let’s start in the mechanical room.

The First Chance To Remove Air – The Mechanical Room

The Bell & Gossett Rolairtrol air separator removes the most air. The B&G CRS Coalescing Removal air/dirt separator follows a close second. The efficiency of these devices is reduced if the air is moved up the separator but cannot get out. If we are going to remove most air at this point, we need a large capacity air vent.

When the air removal is measured in cubic feet per minute instead of cubic inches per minute, many engineers look to the B&G 107A high-capacity automatic air vent. This vent has a ¾” inlet and a 3/8” outlet. It is 4” diameter and 9” tall. Clearly this vent has room to store the air and an opening size to remove it quickly. These work horse vents can remove 200 SCFM at 30 PSIG.

The Key Differences in Automatic Vents

The key differences in vents are the pressure ratings, inlet size, and vent volume. The pressure ratings are obvious. Most engineers specify the 150 PSIG working pressure to avoid having to make the decision on each project.

Next is the inlet size. The inlet is important since that is the opening area that the air must go through, so it does not get swept back into the system. Smaller 1/8” inlets work well on small pipes. On larger pipes we like the ¾” vents.

Vent volume is next. Once the air is in the vent, we need to get it out so more air can come in. The capacity of the vent in cubic feet per minute (CFM) is a function of the orifice size and the pressure. Most of the smaller vents have very small orifice sizes and 1/8” outlet sizes so the CFM is relatively constant across the models. Larger volume vents can capture the air and hold it while it is venting.

Where to Use Different Automatic Vents

Based on the reasoning above, here is a suggested use for various vents used in hydronic systems. The highlighted vents are what I use for general specifications to avoid checking working pressures on every project.

Next week we answer an interesting question about steam condensate units.