Oftentimes an engineer will specify a pump mounted on springs, vibration base, inertia base, or isolation base. Our industry tends to use a number of terms for the same thing. Most often, what the engineer is looking for is a steel frame with springs that are filled with concrete to provide some vibration and movement control.

The proper term we use is inertia base. We normally recommend this base when installing an end suction, double suction, or vertical inline pump on floors above grade. They are also recommended when there is sensitive equipment nearby.

Proper Installation and Detailing of an Inertia Base

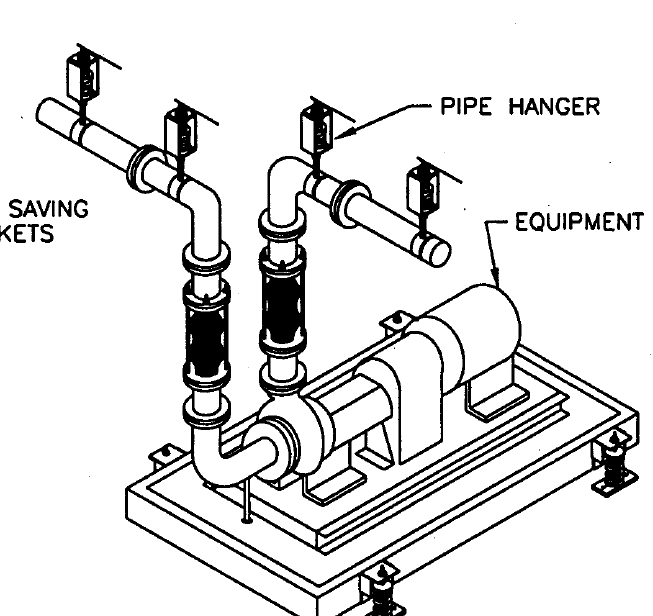

When you show an inertia base under a pump, make sure the vertical piping down to the pump is also supported by the base. Take a look at the piping detail below from Vibration Eliminator Company.

The elbow support at the pump suction is shown on the inertia base, not mounted to the floor. We want the pipe and pump to move together or we cause a shear force on the pump.

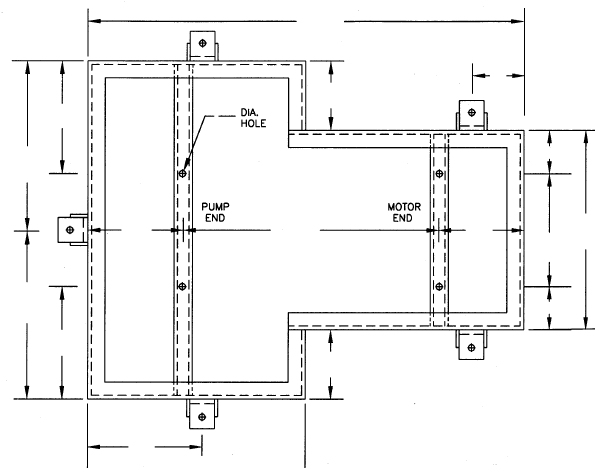

This means that when it’s used on horizontal split case style double suction pumps, the base will look like a “T”.

The Need for Spring Hangers When Using Inertia Bases

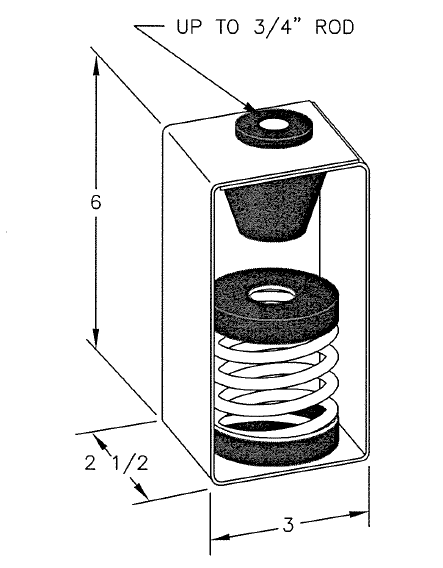

Note the spring hangers shown in the pump detail above. The pump and pipe will try to move with the inertia base. If the headers are anchored to the structure, then the only thing left to move is the flexible connector. If you have 1-1/2” of movement in the base and only 1/8” of axial movement in the flex connector, something is going to break.

ASHRAE and Vibration Eliminator Company recommend the first three hangers on both the supply and return of the pump be spring hangers. Make sure your specification and/or details clearly indicate the use of spring hangers if you are using an inertia base under a pump.