Pump suction piping is one of the areas where problems of frequent repair or noise will originate. There is a lot of confusing information out there. Last week the R. L. Deppmann Monday Morning Minutes looked at strainers on pump suctions. This week we continue with the pump suction piping design by reviewing the suction diffuser purpose.

Suction Diffuser Purpose and Suction Diffusers vs. Strainers

In the last blog, I ended with a paragraph on suction diffusers. The name suction diffuser is really a product name by Bell & Gossett. It is sort of like asking for a Kleenex instead of a tissue. B&G introduced the suction diffuser to solve a problem. Most pump manufacturers who follow the Hydraulic Institute (HI) standards require some pipe diameters of straight pipe into the pump. Many articles and installation instructions (IOM) indicate the straight pipe is to avoid turbulence into the pump suction. Turbulence is important but “swirling” or spinning of the water is the real issue. I’ll address this in detail next week. This is where the suction diffuser shines.

In the last blog, I ended with a paragraph on suction diffusers. The name suction diffuser is really a product name by Bell & Gossett. It is sort of like asking for a Kleenex instead of a tissue. B&G introduced the suction diffuser to solve a problem. Most pump manufacturers who follow the Hydraulic Institute (HI) standards require some pipe diameters of straight pipe into the pump. Many articles and installation instructions (IOM) indicate the straight pipe is to avoid turbulence into the pump suction. Turbulence is important but “swirling” or spinning of the water is the real issue. I’ll address this in detail next week. This is where the suction diffuser shines.

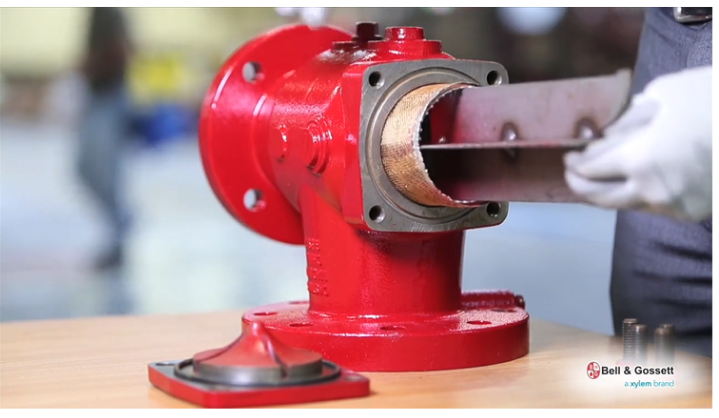

If someone asks, “What is the suction diffuser’s purpose?”, I have a ready response. A suction diffuser is a combination elbow, reducer, strainer, and straightening vane. Anytime you can combine that many functions in one device, it is probably a winner in the battle to reduce labor. Last week’s R. L. Deppmann Monday Morning Minutes addressed the strainer portion. Just by looking at it you can see that it is an elbow. Looking at the models show that it is also a reducer. The suction side should match the pump size and the inlet side can be the same or a larger size. The most important feature is the straightening vanes. The photo below is from the suction diffuser video.

When water is coming out of an elbow or short reducer, it can start a swirling action in the water. If that swirling action continues into the pump, there could be some detrimental effects. The forces at one point in the suction or eye of the impeller could be different than the other side. This will cause some imbalance. Too much imbalance and the owner is replacing seals or other components too often. The vanes in the suction diffuser prevent the swirling and “diffuse” the water into the pump.

Larger Pipe Size Suction Diffusers

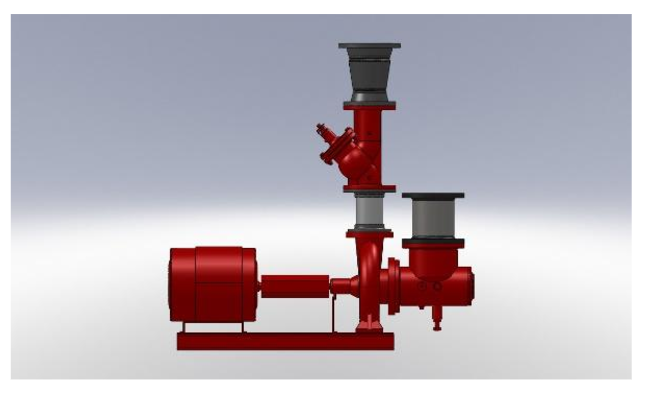

The B&G suction diffuser goes up to 10” in size. This covers a large number of projects, but what happens with the extra-large end suction or side inlet double suction pumps? A company, Flow Conditioning, produces the larger suction diffusers called a “Double Suction Diffuser.” They start at 10” and go all the way up to 24” pipe sizes.

The B&G suction diffuser goes up to 10” in size. This covers a large number of projects, but what happens with the extra-large end suction or side inlet double suction pumps? A company, Flow Conditioning, produces the larger suction diffusers called a “Double Suction Diffuser.” They start at 10” and go all the way up to 24” pipe sizes.

Just contact Deppmann or your B&G representative for more information on larger suction diffusers.

Velocity and Pressure Drop in Suction Diffusers

Sometimes the pressure drop in the suction diffuser becomes too great at the design flow rate. There is a lot going on with all four tasks performed by one product. B&G does not have a maximum velocity or pressure drop published for these products, but the flow can result in pressure drops that the engineer may deem too excessive. This can be the case with 3500 RPM selections and even some 1750 RPM selections.

What do we do if the suction diffuser just does not work well for us? Metraflex has devised a neat solution and we’ll discuss more about that next week.