Printer Friendly (PDF)

Where should the hydronic expansion tank be in a tall high-rise hydronic system design? In part 1 of this article, I identified the size and cost differences if the tank is at the bottom of the system or the top of the system. If the engineer wants to locate the tank at the top of the system, even though the pumps and boilers are at the bottom, how is this accomplished? Today’s R. L. Deppmann Monday Morning Minutes tackles this question.

Where should the hydronic expansion tank be in a tall high-rise hydronic system design? In part 1 of this article, I identified the size and cost differences if the tank is at the bottom of the system or the top of the system. If the engineer wants to locate the tank at the top of the system, even though the pumps and boilers are at the bottom, how is this accomplished? Today’s R. L. Deppmann Monday Morning Minutes tackles this question.

In part 1 of this series, we identified the system. It is a 30-story high rise hydronic heating system. The result was a 20% saving in first cost and a reduction in tank size if the tank was located at the top of the system. So, we know we save thousands of dollars in first cost if the tank is on the top floor. What are we giving up saving this money?

Traditional Expansion Tank Location Benefits

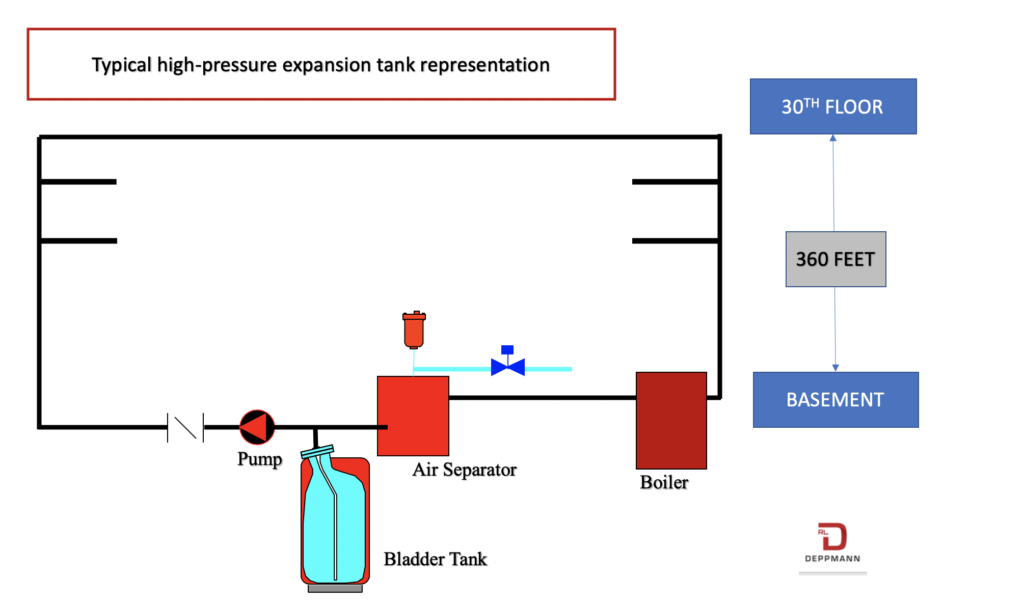

The tank pressure and cold fill pressure would be 160 PSIG in the traditional location of the expansion tank, ((360/2.31) + 4). At room temperature, before heating, the pump suction gauge would read very close to 160 PSIG whether the pump was on or off. The tank is the point of no pressure change so this makes perfect sense. The air separator is located with the hottest water and full flow. The pump is pumping away from the point of no pressure change or expansion tank. The cold fill pressure reducing valve(PRV)is near the expansion tank. The normal rules are being followed.

Top of System Expansion Tank Location

Hydronic Expansion Tank Location and Piping:

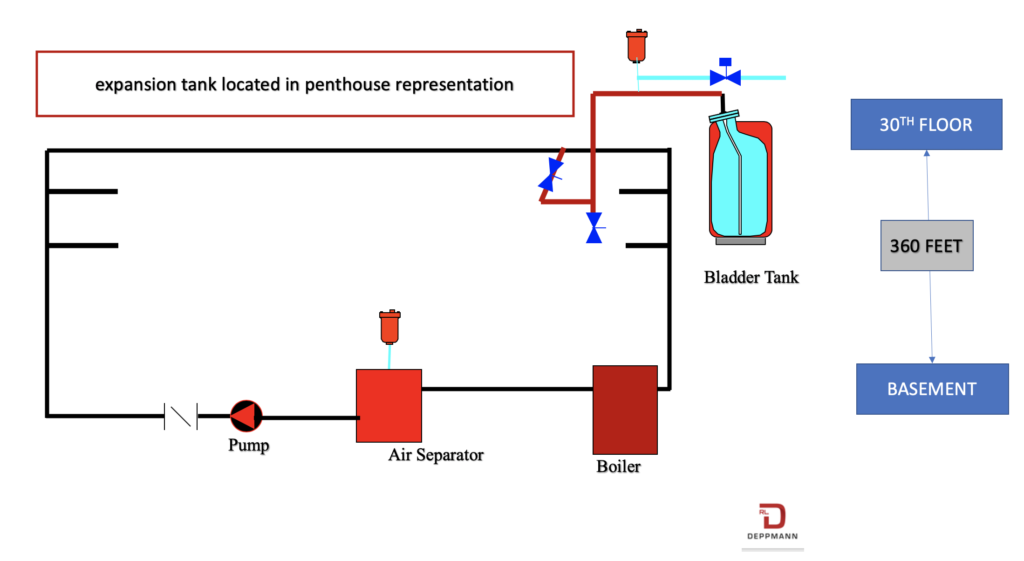

The tank should be located on the hot water return piping after the terminal units. It should end up close to the top of the return riser. It should be piped using the traditional rules, off the side of the pipe with a thermal loop.

Pump Suction Pressure:

When we locate the tank at the top of the system, the suction pressure to the pump will vary with the pump flow rate. The tank remains the point of no pressure change. Assume the cold fill pressure at the tank is 4 PSIG. With the pump off, the suction pressure will be 160 PSIG, ((360/2.31) + 4). Now there is about 400 feet of pipe, a boiler or heat exchanger, and an air separator between the tank and the pump suction. Assume 4’ per 100’ of friction loss and, for this example, 10 feet of drop in the boiler and air separator. If the pump is off, the suction pressure will be the 160 PSIG. If the pump is on, and at full flow, the suction will read 160 minus the friction loss or about 150 PSIG. This is not a problem. It is just a difference.

Cold Fill PRV:

The pressure at the pump suction will vary depending on the flow rate and friction loss in the system. If the PRV is located near the air separator at the bottom of the system, what do I set it at? The traditional 160 PSIG cold fill pressure will result in makeup water being added to the system when the pump is running, and the pressure drops due to friction loss mentioned above. The pressure at the top of the system will rise and the tank may end up being too small. This will cause possible pressure relief valve opening at full temperature.

For this reason, if the tank is located at the top of the system, the cold fill pressure reducing valve should also be located there.

Air Separator:

By locating the hydronic expansion tank at the top pf the system, there will be some deviation from my rules shown in Air Separator Location in Hydronic Systems. You could make an argument to locate the air separator at the top of the system. It would be at the lowest pressure and allow any air coming from the city water makeup to first flow into the air separator. It would not be the hottest temperature. The deciding factor has to do with flow. Most systems of this type would have a direct return set of mains. The floors may be reverse return, but the mains are normally direct return. Very little of the full flow rate would be available at the top of the system. Whether the tank is in the basement or the top, the top floor would contain many air vents in the system. I would keep the air separator in the lower level after the boiler.