In the last R. L. Deppmann Monday Morning Minute we covered the use of a B&G Triple Duty Valve to set the maximum speed in a variable frequency drive (VFD). If we can simply turn a drive speed down to reduce over-headed pump energy, why ever trim an impeller?

The ASHRAE Standard 90.1-2013 and the State of Michigan 2015 Energy Code both require the trimming of impellers or reduction in the maximum speed when pumps 10 HP and above are oversized and the energy savings is 5% or 3 HP, whichever is greater. How does trimming an impeller or changing the speed of a VFD accomplish the same result?

Over-Headed Pump Operation with Trim and Speed Setting

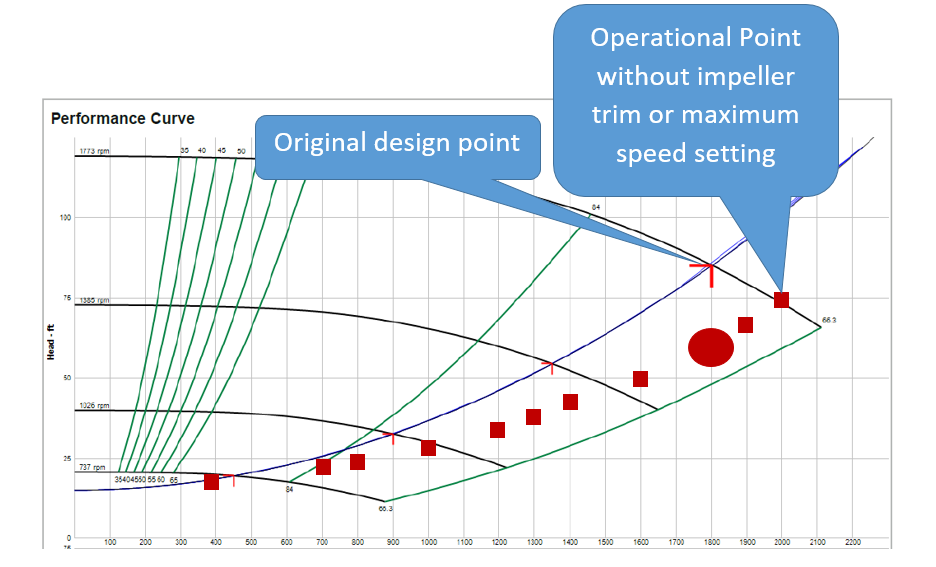

Take a look at the curve below. The engineer selected a pump for 1800 GPM at 85 feet. We find the pump oversized when the triple duty valve is used with a proportional balance method. The actual head required at 1800 GPM is 60 feet. The new required head of 60 feet establishes a new system curve represented by the dots.

What is Involved with Trimming an Oversized Pump Impeller?

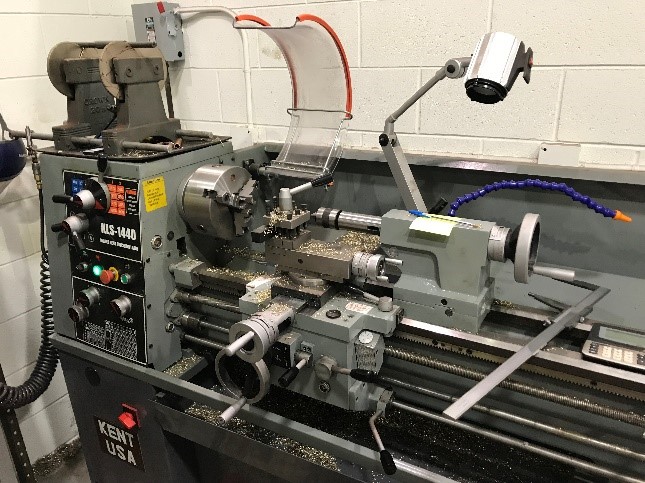

Once a pump is installed and commissioned, removal of the impeller for trimming can become costly. There is the labor to:

- drain the pump and remove the impeller

- trim and balance the impeller

- reinstall the parts

If the pump has operated for any length of time, the seals may also have to be replaced.

Here is a short video of one of our employee owners trimming and balancing an impeller.

When Should You Trim an Impeller?

Obviously, if you don’t have a VFD, the only way to meet the Energy Code would be to trim the impeller. What if you have a drive? Would you ever trim an impeller?

VFDs are very reliable these days. There are still specifications that require what is known as a “Bypass” or “Bypass Starter”. Some systems are so critical, or steady voltage is so unreliable, that the engineer will ask for a manual bypass. This is a starter or contactor installed in the drive. If the drive trips due to voltage variations or other reasons, the starter may be manually or automatically engaged. When you do this, any maximum speed adjustment disappears. This could be deemed an emergency condition and may be considered by an inspector as outside the scope of the Energy Code. That said, the pump operation may be at a place where you would not want it operating due to shortened pump life, overpressurization, or energy cost. If any of these conditions are a concern, trim the impeller. One thing I always say is that if you have a bypass starter, someone will use it!

One final thought: if an electronic drive is going to stop because of an electronic issue, does it make sense to have an electronic contactor as the backup? If you are adding a bypass starter, make sure the drive is either a Bell and Gossett drive or a Danfoss drive. Both of these manufacturers understand the issue and use a mechanical contactor as part of their bypass options.

If you require any further information about impeller trimming or variable frequency drives, our knowledgeable staff at R. L. Deppmann is ready to help you make a better decision.