The installation of hydronic and steam flow meters often involves a term simply stated as “minimum pipe diameters.” You may hear that a meter or balance valve requires “10 and 5” or “5 and 3.” These common phrases refer to the lengths of straight pipe before and after the meter or balance valve. The proper installation of flow meters is critical to accuracy and repeatability. What happens when something is different? There is more to this story.

The installation of hydronic and steam flow meters often involves a term simply stated as “minimum pipe diameters.” You may hear that a meter or balance valve requires “10 and 5” or “5 and 3.” These common phrases refer to the lengths of straight pipe before and after the meter or balance valve. The proper installation of flow meters is critical to accuracy and repeatability. What happens when something is different? There is more to this story.

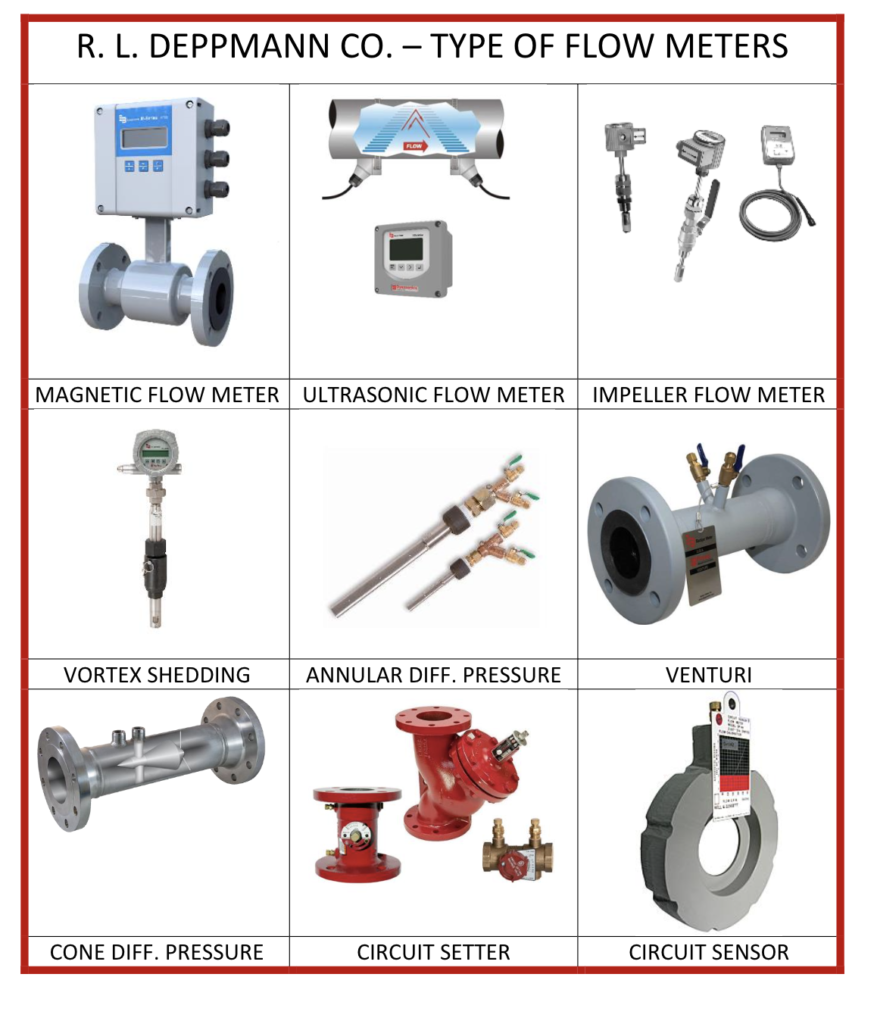

Types of Flow Meters and Balance Valves

The required pipe diameters changes with the type of flow meter installed. Here are most flow meters used in the HVAC and plumbing systems. These photos will help you determine the type of device you have.

This article does not address the pros and cons of each type of flow meter. I did just read an interesting article on steam flow measurement. Brian Kettner of Badger Meter wrote a good article for Engineered Systems magazine on the advantages of cone technology in “Large Institutional Facilities Optimize Steam Measurement with Differential Pressure Flow Meter Technology.” The cone technology offers very tight mechanical room installation advantage which may help in steam applications.

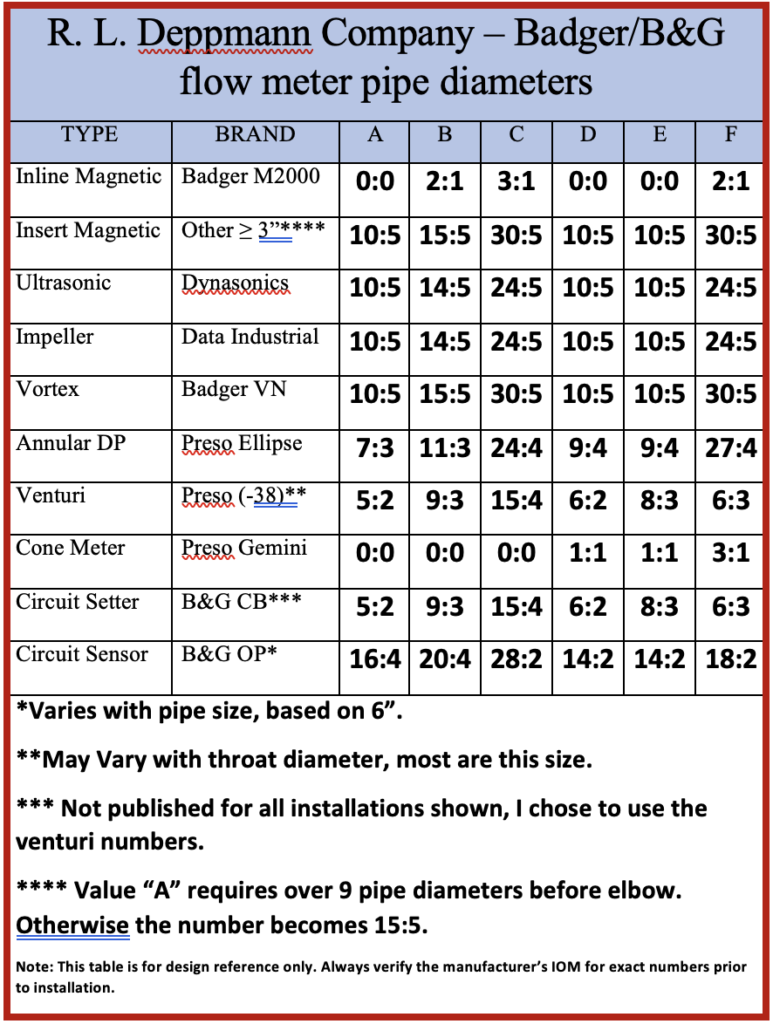

Pipe Diameters Required for Flow Meter Installation

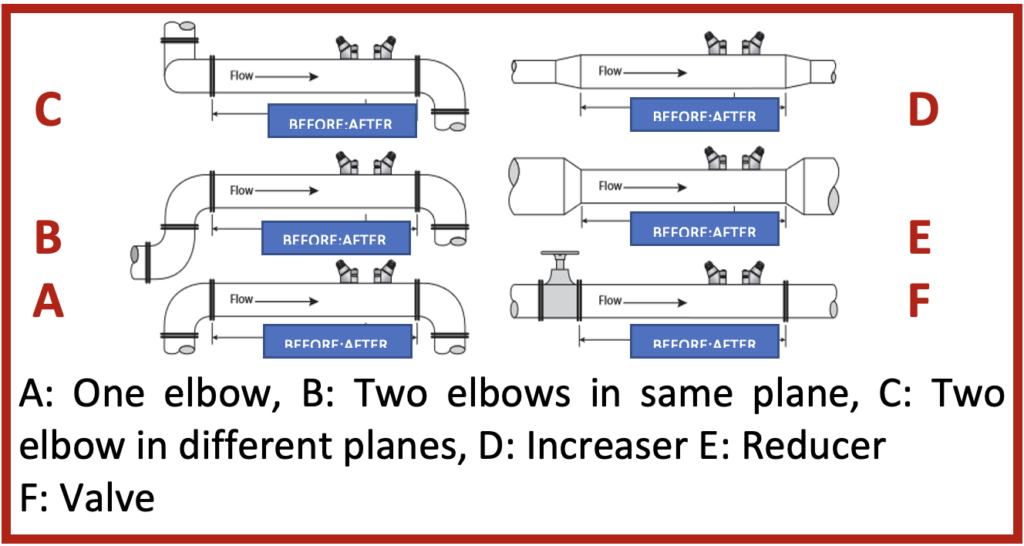

Manufacturers usually show the recommended location of the flow meter in the installation, operation, and maintenance manual (IOM). I have summarized the common installations and show you the pipe lengths for Badger Meter and Bell & Gossett. These are similar to other manufacturers. Please check the appropriate literature for other manufacturers or if the exact accuracy required is tight for your installation.

What does the chart show?

- Amount of un-obstructed flow required upstream and downstream of a flow meter to ensure accurate measurement. (Required “real estate” for flow meter). Without proper straight pipe, meters become less accurate, repeatability comes into play

- The length of pipe required changes based on nearest up and downstream obstructions. Pumps/butterfly valves typically require the most straight length of pipe.

- Without proper straight pipe, meters become less accurate, repeatability comes into play.

Flow measurement and balance in hydronic, steam, and plumbing systems are critical. Proper installation will go a long way towards accurate readings of the flow rate.