This being the last article in this series, I turn your attention to double suction pump efficiency. I will also share some information on pump efficiency in general. Finally, we have a link to download the Double Suction Pump Specification at the end of this post. That is a lot of information in just one R. L. Deppmann Monday Morning Minutes.

Let’s start with the Bell & Gossett (B&G) series e-HSC double suction pump efficiency.

B&G e-HSC Double Suction Pump Efficiency

In our article, Department of Energy Pump Standards – Modify Your Specification, we explained that Bell & Gossett led the pack in publishing their efficiency data into the Hydraulic Institute Energy Rating Database for the pumps covered under the Department of Energy Standards for Centrifugal Pumps. B&G already improved the efficiency of their end suction pumps long before the DOE standard was published. Double suction pumps are not part of the DOE standards. Without the concern and requirement of government regulation, B&G has redesigned the e-HSC double suction pumps to improve efficiency. You will find, for most GPM and head combinations; B&G leads the pack in efficiency in the e-HSC and VSX series of pumps. Try some selections in the ESP-Systemwize program to see results.

If you select pumps and check the e-HSC and VSX buttons, you will get some of the best efficiencies in pumping. Even though the e-HSC is efficient, the VSX will often do better. Best to check them both.

Do You Want to Know a Secret?

What I am about to tell you is no secret but it was news to me. I love our industry and I learn something new every day, but after 42 years, I learned something new about efficiency tests. Knowing this may help you stay out of trouble someday.

Let’s start by repeating what I have said for decades. I will trust the flow and head reading on a B&G pump more than I believe the flow through a standard hydronic balance valve. I go to sleep knowing the pumps I provide will do what the curve says.

When I select a pump for a closed circuit application, I usually look for GPM, Head, Efficiency, and non-overloading Horsepower. I try to pick the pump that tempers first cost with efficiency while not getting too close to the end of curve. In that process, I may pass up a lower priced pump, for example, at 76% efficiency and select one at 80% efficiency. What I found out recently is that although I scheduled an 80% efficient pump, I might lose the order to a manufacturer with a pump that operates at 76%.

It is not surprising that there are tolerances in the Hydraulic Institute testing procedures that allow some wiggle room between the published curve and the actual performance. I was surprised by how much tolerance there actually is.

Hydraulic Institute Grades of Centrifugal Pump Testing Tolerance

The Hydraulic Institute (HI) section 14.6 defines the default acceptance grades for “Building Trades and HVAC.” Pumps with peak power at 134 HP or less have a tolerance grade of 2B. Pumps with a peak power greater than 134 HP have a 1B tolerance. You may ask, why should I care?

A 2B testing tolerance allows the actual flow rate to deviate from the published curve by ±8%, the head by ±5%, and the efficiency to miss the published amount by a negative 5%.

Imagine what a mess this could cause if the pump you selected was non-overloading but the horsepower curve was close to the impeller curve. Imagine what would happen to that unforgiving variable frequency drive (VFD) if you try to exceed the current rating of the drive.

Although B&G is only required to meet the 2B testing tolerance, they are conservative and don’t publish the “dream pump” but instead publish the “real pump.” I did not know this until I started this series of articles, but I understand why I can sleep at night, even though the testing tolerance is so generous.

A Hydraulic Institute testing grade of 1B would change the efficiency miss to only -3%. B&G is quite confident that its new e-HSC double suction pump would meet the 1B test with no modifications needed. Unlike many competitor legacy products that have not had curve updates in years, this product is fresh off the test bench.

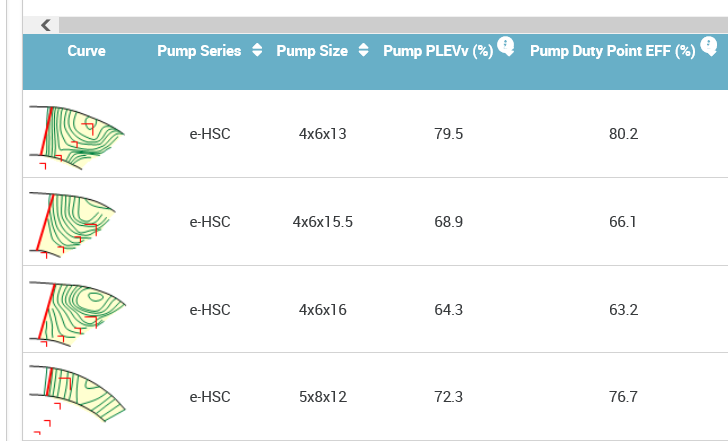

Here is a screenshot of the ESP-Systemwize selection program. You may choose the 80.2% efficient pump but a pump tested under the 2B standard could be as low as the 76.7% efficient pump you did not choose. The submitted pump may say 80.2 but under the 2B testing method, it could be operating down at 75.2% efficiency.

Testing Tolerance and You

It is true that a company can inflate its efficiency numbers and then standardize on a 2B acceptance grade since they know their pump will never achieve the published values. In many cases, the efficiency values of trimmed impellers may only be calculated and are not the result of testing. Specifying a 1B tolerance would cause them to be more “honest” and decrease the published efficiency value, or make modifications to improve standard efficiency (close clearances, polished volutes, and impellers).

The issue is the proof. I doubt that manufacturers would lie. The consequences would be major. The only true way to verify the efficiency or power is to factory test. That adds cost and time to the pump getting to the job site. I could suggest you specify a 1B acceptance grade in your specification. If you are interested, please feel free to contact us or your B&G representative.

What I would be careful of are pump curves that run close to the horsepower curve. Possibly a statement that the provided HP shall be no less than 105% of the non-overloading BHP. I would suggest you remember there is an R. L. Deppmann Monday Morning Minute with this topic if you run into a problem in the field with drives, flow, head, or horsepower.

The Perfect Double Suction Pump Specification

If you have followed this series, you have the knowledge to understand what you specify and defend it. I have identified in red any benefits provided by B&G that would possibly be deemed proprietary. I have all of the suggestions made in this series as a free downloadable document below!

To receive a copy of our Double Suction Pump Specification, simply fill out the form below.

Catch up on the most recent Monday Morning Minute where I discuss Double Suction Pump Specification: Coupler & Bases.

Next week, I have a clarification in response to your inquiries on the DOE Pump Standards in the R. L. Deppmann Monday Morning Minutes.