Hot water plumbing system design is a hot topic. The building plumbing design/engineering team is faced with a variety of new products, standards, and codes. Many of today’s standards involve pathogen mitigation. Some engineers may proactively offer advanced mitigation to the client as an option. This team must consider water quality, proper disinfectant levels, stagnation, and owners needs for recording and reporting. All of this while combing the industry for new talent and trusting in that new talent’s experience.

Hot water plumbing system design is a hot topic. The building plumbing design/engineering team is faced with a variety of new products, standards, and codes. Many of today’s standards involve pathogen mitigation. Some engineers may proactively offer advanced mitigation to the client as an option. This team must consider water quality, proper disinfectant levels, stagnation, and owners needs for recording and reporting. All of this while combing the industry for new talent and trusting in that new talent’s experience.

Hot Water Service: More than the Water Heater

The center of the plumbing hot water system is, of course, the water heater. The heater must provide the proper amount of hot water to satisfy the needs of the building occupants. The engineer should design the water heater storage and supply temperatures with pathogen growth in mind.

The heater should be able to provide very hot water when needed for Legionella system temperature disinfection processes. Whether tank style or tankless, the engineer should consider a water heater which will operate in disinfection mode without personnel making manual adjustments. We also want a water heater that has a high efficiency to reduce operating costs. The R. L. Deppmann Monday Morning Minutes have many articles about high efficiency water heaters. The story does not end there.

Water Wellness in Plumbing Design

The engineer must design the hot water system as a whole and select and coordinate hot water system components to operate with each other. Here are some of the considerations.

- Water that is too hard may, at a minimum, void warranties of equipment. Hard water may also foul and clog safety equipment putting occupants at risk. Any proactive means to eliminate pathogens may have limits to the hardness of the water. Addressing water quality is the first step. The blog Water Heaters & Hard Water: Template Assisted Crystallization may help.

- Dirt and particulate in the supply water should be addressed. Whether coming from a well or introduced after a municipal power outage, dirt can affect system components and safety devices. Will your system need some sort of filter?

- Many system designs require an ASSE 1017 mixing valve. The owners’ pathogen plans may include a high temperature sterilization plan. At this point we suggest a digital mixing valve. This allows the owner or the control system to adjust the temperature for the short sterilization cycle and then return to the safe design operating temperature. With digital systems, this can be built into a control scheme.

If a self-contained ASSE 1017 valve is used, the owner’s staff will have to adjust the temperature or isolate and open valves to achieve temperatures over 150⁰F for system disinfection. After the disinfection process, the safe water delivery temperature is subject to a correct manual adjustment back to the design point.

The DigiTemp™ and DigiTemp Jr. by PVI are examples of digital 1017 technology.

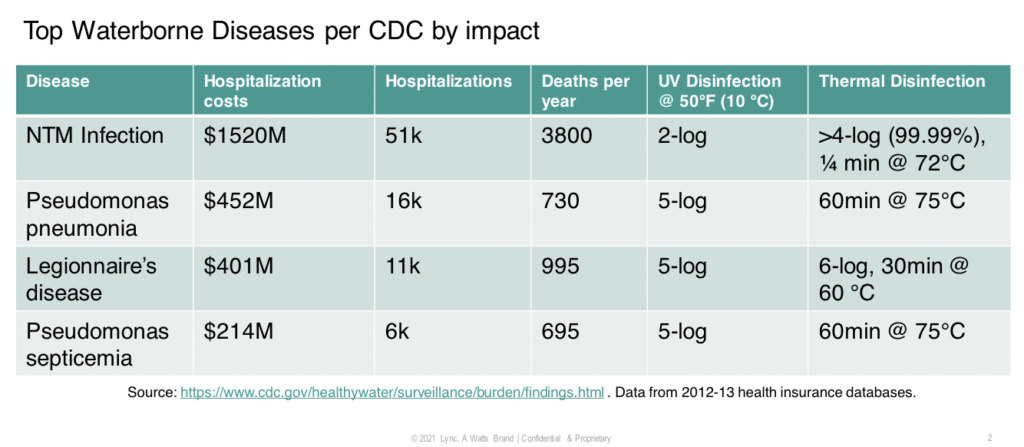

Ultraviolet Disinfection

- One engineering tool for Legionella mitigation is to prevent the bugs from reproducing by using UV as they enter the system. Damaged pathogens will die off. An environmentally friendly UV system requires no chemicals and produces no chemical byproducts. The owner’s personnel do not have to handle or store chemicals.A UV system with a 5-log effectiveness will reduce 99.9999% of the front-line pathogens. The system does use power so automatic lamp dimming is a nice feature.Communication with the controls system including alarms and yearly maintenance notifications is helpful for busy maintenance personnel. High efficiency reactor chambers will increase the UV dosing efficiency and ensure the UV light can penetrate the cell walls of the micro-organisms and destroy their ability to replicate

- Controls, recording, reporting, and alerting methods are critical for your client. Each year there are more requirements for your client to have and use a water management program. Proper control systems will do more than just meet requirements; they will save lives. One of the most recent examples, effect January 1, 2022, is from the Joint Commission.The Joint Commission is an independent, not-for-profit group in the United States that administers voluntary accreditation programs for hospitals and other healthcare organizations.Hospitals, Critical access hospitals, and nursing care centers are required to have a water management program. Most of these types of programs require significant owner recording and reporting. The engineer will gain client satisfaction by providing systems which reduce the manual load.The Centers for Medicare and Medicaid Services also require Legionella policies and prevention procedures in their QSO-17-30 document.

A Packaged Solution Saves Time and Risk

Element-Q is a complete engineered packaged hot water wellness solution from Lync by Watts. This solution provides all the integrated parts and pieces into a pre-piped, preconfigured, space saving package. This saves the engineer design time, reduces onsite installation time by the contractor, and limits the risk associated with a wellness system.

The next R. L. Deppmann Monday Morning Minutes will introduce more details about the product and the unique recording and reporting solution it provides the client. We also have an exciting new virtual training session if you want to better understand the value of specifying this product.

Our Water Wellness and ASHRAE 188 Seminar will take place on Wednesday, January 19 from 12:00pm – 1:00pm EST. Click here for seminar and registration details. This webinar is eligible for 1.0 CEU of Continuing Educational Units.