The blistering hot weather here in southeast Michigan caused me to turn my attention to cooling tower pumps and their control. Cooling tower pump control is traditionally on/off constant speed. If the tower is on, the pump is on. What happens if the balance report comes back with a throttled discharge balance valve? Should we be considering variable speed on tower pumps?

The blistering hot weather here in southeast Michigan caused me to turn my attention to cooling tower pumps and their control. Cooling tower pump control is traditionally on/off constant speed. If the tower is on, the pump is on. What happens if the balance report comes back with a throttled discharge balance valve? Should we be considering variable speed on tower pumps?

Cooling Tower Pumps and Safety Factors

Cooling tower pumps are normally oversized. The engineer may have two or three choices of chiller manufacturer and take the worst pressure drop in the design. Different manufacturer’s cooling tower height will vary and result in the additional head in the calculations. Many engineers will add an allowance for strainer plugging during operation. Then we have the 15-20% safety factor added on to the pump head.

None of these additions to the pump head would be considered excessive in a design where the final manufacturers and contractor is unknown. The balance contractor will complete their adjustments and throttle the discharge balancing valve. This process was described in my Balancing & Trimming Hydronic Constant Speed Pumps blog. I’ll be adding some ideas for the balance contractor in a couple of weeks. At this point, I will just add from experience that 95% of all tower pumps are oversized but less than 5% have the impellers trimmed. The reason “why” might be explained as: you cannot glue it back on once the impeller is trimmed.

What is my Throttled Triple Duty Valve costing me?

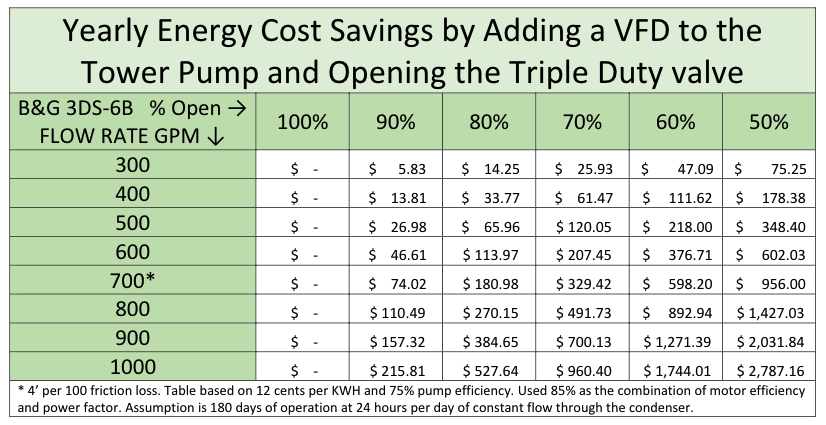

A throttled valve will cost money during operation. Whether it is provided as part of a combination valve on the pump discharge or a balancing valve. Take a look at the photo above. The valve shown is 40% open. That is severe. What if it was only set at 80% open or 70% open. How much is it costing the owner?

Let’s look at some numbers. Assume you have a 6” balanced Bell & Gossett (B&G) triple duty valve on the tower pump. How much does it cost to have it throttled vs. wide open if the energy cost is 12¢ per KWH? Of course it depends on the design flow rate.

If this 6” triple duty valve is throttled over 30%, it is worth looking at the cost of converting to variable speed.

Installed Cost of a Variable Speed Drive

Engineers may want to consider a VFD in their new construction projects. Today’s premium efficiency motors have the higher insulation level required for the heat buildup due to variable speed operation. An older installation may require a motor upgrade.

The installed cost of a drive will vary depending on your location. In Michigan, I can assume about $300 per horsepower for an installed drive. This would give you a Bell & Gossett VFD and an assumption that the electrician is on-site doing other things.

If the example pump is 15 HP, our drive cost would be about $4,500 installed. It is clear to see that the simple return becomes real money when the triple duty is throttled by over 30%.

Utilities and Rebates

Many electric utility companies have or are looking at rebates for tower pumps. Make sure you ask. A large portion of the drive cost may be available as a rebate. Even if there is no published program, it is worth an email or call. Utilities often have funds set aside for special programs. If you are in Michigan or Northern Ohio, just click on the link here and ask us to look at your system. If you are elsewhere, ask your B&G representative to help you review the pump operation and possible savings.

In part 2 of this series, we will look at tower pumps with multiple condensers.