The marketing directive is clear in the hydronic condensing boiler world. Make sure you highlight high efficiency in every boiler advertisement and bulletin. So before you select and schedule the boiler of your choice, remember that the published AHRI efficiency should always have a footnote: the boiler efficiency will be less with higher temperatures.

The marketing directive is clear in the hydronic condensing boiler world. Make sure you highlight high efficiency in every boiler advertisement and bulletin. So before you select and schedule the boiler of your choice, remember that the published AHRI efficiency should always have a footnote: the boiler efficiency will be less with higher temperatures.

Boiler Efficiency and Return Temperature

Every condensing boiler manufacturer publishes their impressive literature touting 96% to 98% efficiency – or more. That efficiency is determined under controlled test laboratory conditions and does not reflect installed operating conditions. Boilers are tested by the Air Conditioning, Heating, and Refrigeration Institute, or AHRI. The AHRI test conditions are shown as section 5.3.5.2 Condensing Boilers. According to the AHRI, “for condensing boilers, the outlet temperature shall be 180°F ± 2°F and the inlet temperature shall always be 80°F ± 5°F during the test”.

How many of your installed hydronic designs have a return temperature of 80⁰F? The answer is not many.

Boiler Efficiency at Design Return Temperature

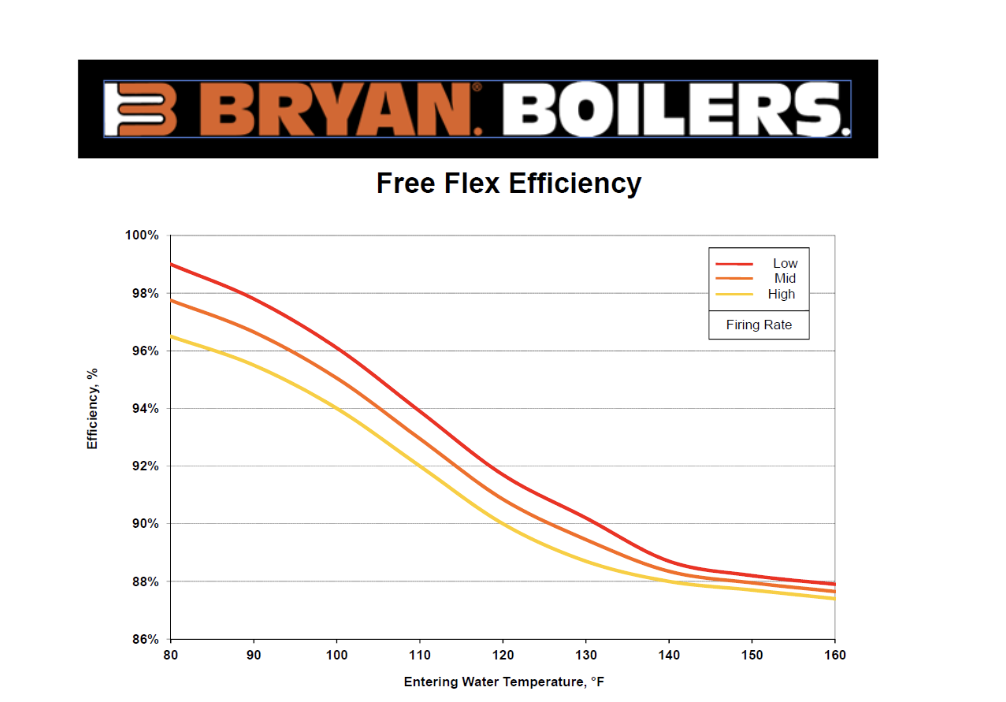

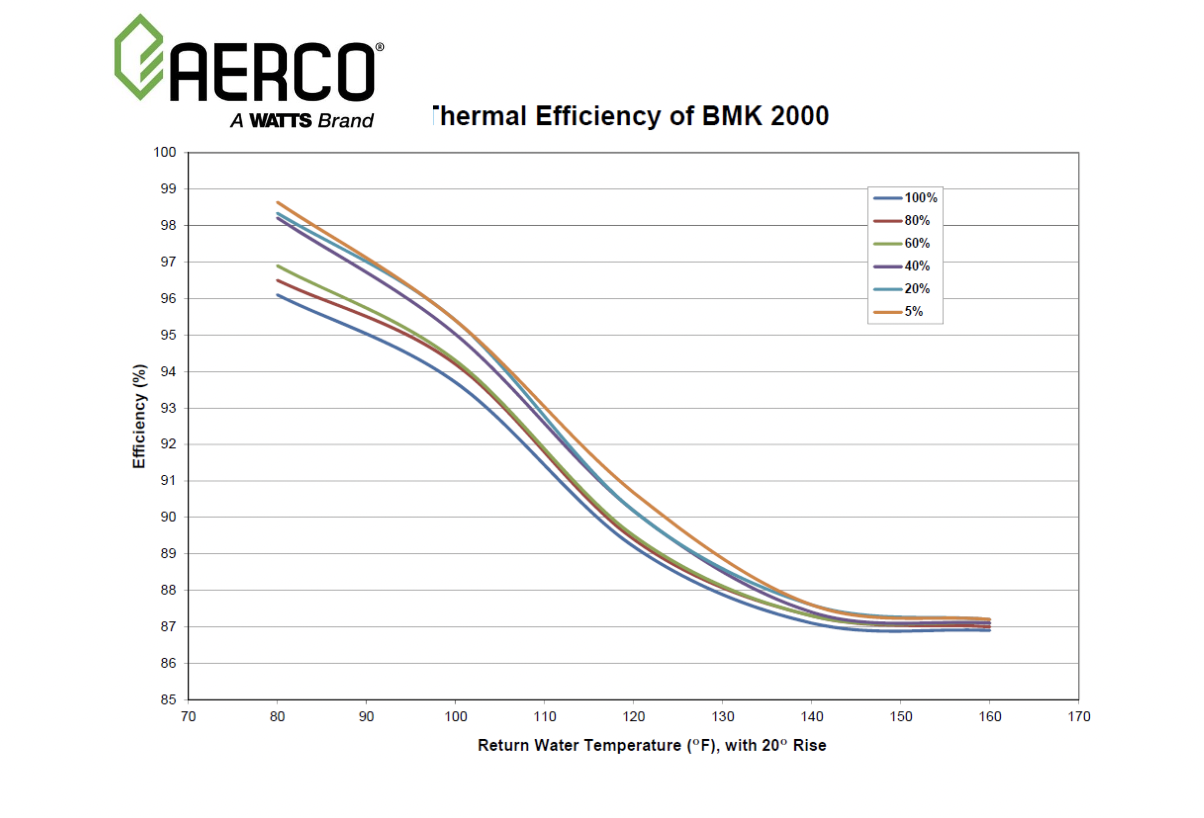

The engineer could have issues if the advertised efficiency is used in design without first looking at the efficiency curves. Here are two examples:

Here is a Bryan Free Flex FF-2000 water tube condensing boiler. We can see that the AHRI rated efficiency of this boiler is about 96.5% with an 80⁰F return. The efficiency with a 150⁰F return is about 87.8%.

Here is an Aerco BMK-2000 fire tube condensing boiler. We can see the AHRI efficiency of this boiler is about 96.1% with an 80⁰F return. The efficiency with a 150⁰F return is about 86.8%.

Do not misunderstand, these are high-quality boilers. The problem isn’t that the boiler is doing a poor job, but rather that the testing conditions used to determine the advertised efficiency are not realistic to the conditions that this equipment will normally be operating at in the real world.

Example Schedule to Highlight the Issue

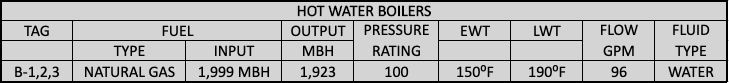

Here is a schedule on a project R.L. Deppmann recently quoted. If we take the output capacities of this boiler we will need:

BTUH OUTPUT=96 GPM ×190-150×500=1,920,000 BTUH

This agrees with the schedule. But look at the input BTUH. What efficiency was used to determine that a 2 million BTUH boiler is needed?

Efficiency=1923/1999 = 96.2%

The AHRI published efficiency was used. The return temperature is not 80⁰F at design but 150⁰F. Therefore the boiler will not be 96% efficient, but something less. If either of the boilers shown above is used, what would the output be?

BRYAN BTUH OUTPUT=2,000,000 BTUH INPUT × .878=1,756,000 BTUH

AERCO BTUH OUTPUT=2,000,000 BTUH INPUT × .868=1,736,000 BTUH

Neither the water tube nor the fire tube boiler will meet the 1,923 MBH output given a 150⁰F design return temperature. In fact, none of the condensing boilers on the market will be able to produce the required output at these temperatures.

Select the Boilers with the Correct Efficiency Curves

Always ask the representative or manufacturer for the efficiency curves so you can schedule the proper boiler. If the representative tells you the AHRI efficiency is good for all return temperatures, it’s time to get another representative. Or better yet, work with R. L. Deppmann Company for the correct solution – guaranteed.