Hopefully, the message from past R. L. Deppmann Monday Morning Minutes was clear: don’t lift the condensate out of a steam heat exchanger or coil with a modulating control valve. If a gravity return main is not located below the steam trap, what do we do? Of course, the answer is to use a condensate return pump. This segment of the steam and steam heat exchanger basics series explores condensate return units.

The purpose of a condensate return unit or condensate return pump is to lift the condensate to overhead mains in order to get the water back to the boiler room and the boiler feeds pumping unit as fast as possible.

The purpose of a condensate return unit or condensate return pump is to lift the condensate to overhead mains in order to get the water back to the boiler room and the boiler feeds pumping unit as fast as possible.

Condensate Receiver Sizing

The receiver is typically made from cast iron or steel. Personally, I recommend cast iron construction over steel every time; the budget can stand the slight increase in initial cost, particularly when you consider the fact that Bell and Gossett’s Domestic brand of cast iron receivers come with a 20-year warranty. Given the low PH of the aggressive condensate, steel would be a poor second choice.

The receiver NET STORAGE capacity is normally sized for one minute. Let’s look at an example. Assume we have a heat exchanger with 7,000,000 BTUH output scheduled and 5 PSIG steam in the shell of a shell and tube heat exchanger. The 5 PSIG steam has a latent heat of 960 so the pounds per hours (PPH) is approximately 7300 PPH of condensate. PPH times .002 will give 14.6 GPM design flow rate into the receiver. This would normally be the required receiver net storage.

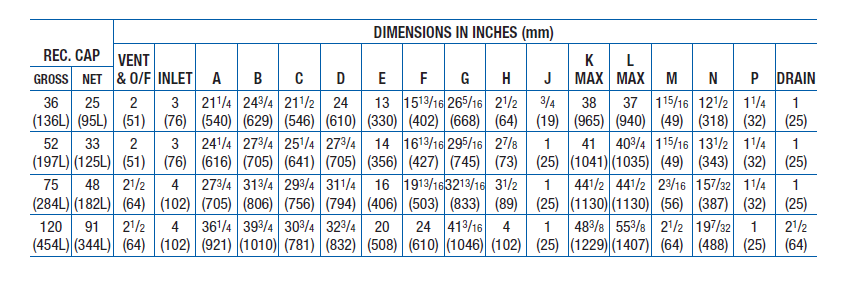

There are some other considerations. Will there be more condensate at times due to warmup load or oversizing of the control valve? Previous MMM articles described some of the reasons that trap sizing safety factors are used during operation. For this reason, if there is a boiler feed receiver in the boiler room, I like to multiply the condensing rate times 1.5 for coils and heat exchangers. This also matches the trap sizing. 14.6 GPM times 1.5 is about 22 gallons of NET storage. Looking at the Domestic receiver size options, select a 36-gallon receiver, which has a net storage capacity of 25 gallons between the float levels of on and off.

Condensate Pump Sizing

Given the net storage capacity of 25 gallons in the receiver, the pump is selected for twice the condensing rate or 44 GPM. These selections are normally rounded to specific standard choices, which in this case 45 GPM.

The pump head is a combination of the elevation needed to lift the condensate, the back pressure in the main or tank we are pumping into, the friction loss of the wet return pipe, and a safety factor. The safety factor is much heavier than it is in a hydronic system, simply because wet return pipe will clog up over time. Bell and Gossett normally suggest 5 PSIG for low pressure and 10 PSIG for medium pressure systems.

In our example, let’s assume the elevation is 10 feet (4.4 PSIG) to the return main and assume there may be 10 PSIG at times in that main. We calculate, for this example, the pressure drop of pipe and valves to be 15 feet or 6.6 PSIG. The pump head is normally expressed in PSIG for condensate pumps. This example would have a pump head of 4.4 + 6.6 + 10 + 5 = 26 PSIG pump head. Again we tend to round up to the nearest standard pump offering which is 30 PSIG. So our pump capacities are 45 GPM at 30 PSIG.

Next week, the R L Deppmann Monday Morning Minutes will examine condensate return pump temperature and NPSH.