Part 1 of this series described the difference between electrode conductive electric humidifiers and resistive electric humidifiers. The article ended by showing a significant cost difference between the two types. Why would an engineer choose the more expensive resistive type design?

Part 1 of this series described the difference between electrode conductive electric humidifiers and resistive electric humidifiers. The article ended by showing a significant cost difference between the two types. Why would an engineer choose the more expensive resistive type design?

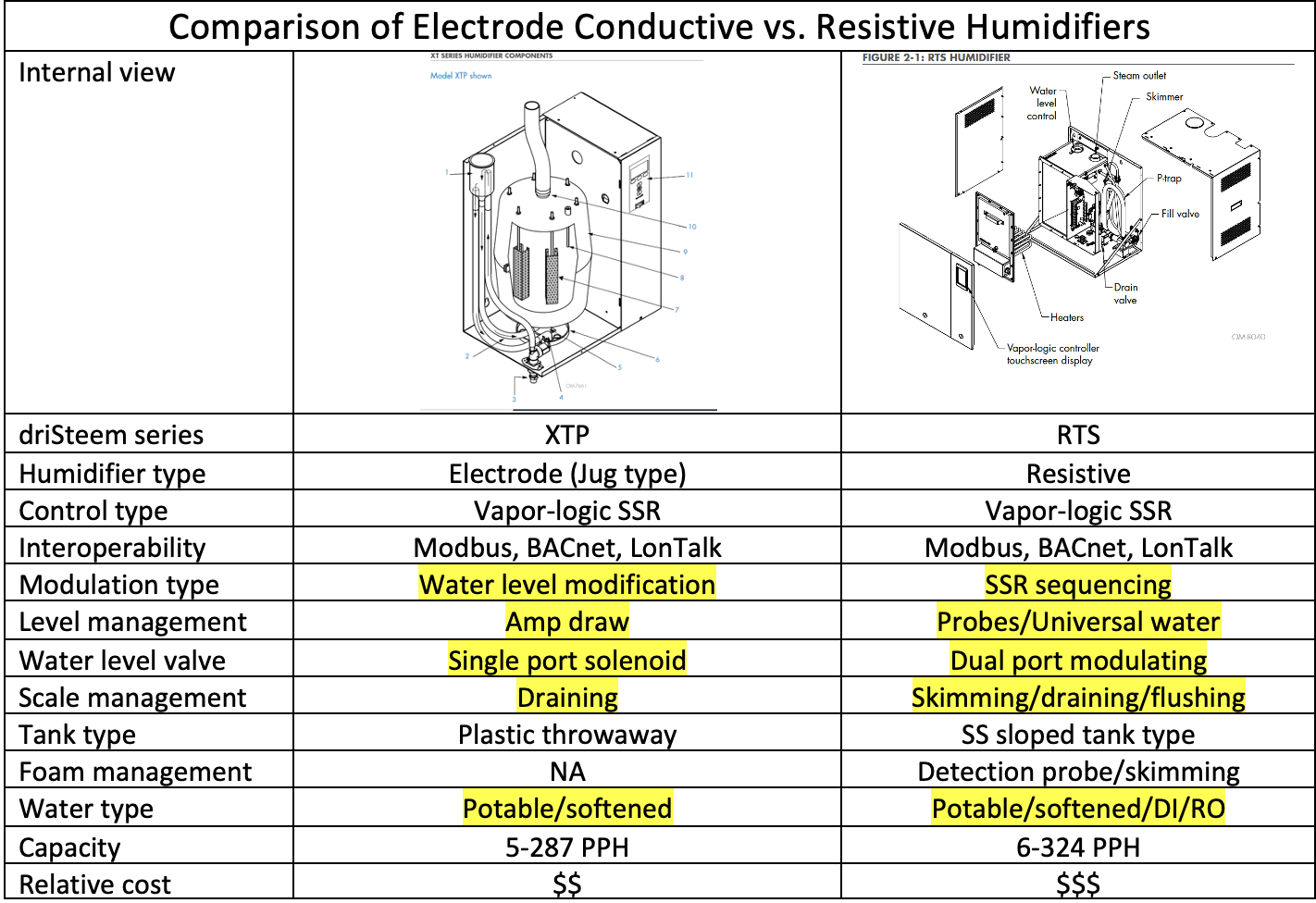

Immersed Electrode Conductive Vs. Resistive Humidifiers

There are many brands of humidifiers for use in commercial and institutional buildings. To compare the two types of electric humidifiers, I will use the driSteem series XT and RTS with the appropriate options I would normally recommend for a larger building with a building management system. Do not assume all competitors have the same valuable benefits built into their products.

The highlighted benefits will be discussed later in this article. Those benefits should be requested in the specification if you choose the more expensive resistive type humidifier.

Water Quality and Cylinder Life

The electrode conductivity type of humidifier relies on the water to create the amps to heat the water. Water quality becomes important. If the water is softened too much, the humidifier may not function properly. If the water is too hard, the mineral build-up will accelerate, and you will be replacing jugs many times per season.

Many humidifiers use RO or DI water to reduce maintenance. This will not work in a jug-type humidifier since the water conductivity will be too low. For more information, driSteem has a publication called Humidification and water type.

The prudent choice is resistive humidifiers if the water type is questionable for the use of electrode cylinder style humidifiers.

A Need for Constant Humidity

Many applications require a narrow band of humidity control. Museums demand tight control and may even monitor the RH with alarms when out of range. I remember working on The Charles H. Wright Museum of African American History. The Smithsonian was providing some very valuable pieces to the museum. They required a data readout assuring the space humidity remained in a tight range for 7-10 days 24 hours per day before they would ship the priceless pieces for display.

Obviously, humidification was important. Today the humidification equipment and controls from driSteem are even better than in 1997.

Do You Require Constant Humidity Levels?

Museums are not the only facilities that expect constant humidity control. Health care operating rooms, some manufacturing, laboratories, and others do not want a drop in the humidity at any time.

The highlighted areas in the chart above are water level management, water level valve, and scale management. There are two times when space humidification will falter during normal operation:

1. The first is for scale management, the boiling water drains and cold water fills the humidifier.

2. The second occurs if the scale build-up is so great that maintenance is required.

This is where a resistive humidifier such as the driSteem RTS really shines. The jug-style humidifier will eventually need to be replaced. When that time comes, it simply stops working and alerts the BMS of the condition. It can alert that it is getting close to replacement but that assumes the maintenance staff can drop everything and go change the cylinder. This does not happen with resistive humidifiers.

The other shining moment for the RTS is on the fill cycles. This unit has a Smart mini-fill cycle. When a humidifier dumps the tank for scale management, it fills with cold water. This causes a gap in humidification control. The Smart mini fill cycle will drain and fill slowly so there is no disruption to the steaming operation. In fact, the controller even adjusts the rate of fill to match the load. The two-ported fill valve allows this to happen without slamming valves open and closed.

Finally, if your client would be concerned about gaps during maintenance, you can use RO water to significantly reduce maintenance.

When Should I Spend More for a Resistive Electric Humidifier?

By now the story is clear. You chose an electric humidifier vs. gas-fired or steam to steam. You have a commercial building where continuous humidity is not critical. You are comfortable with the water quality. You have a client where the first cost of construction trumps life cost. Use an electrode conductivity jug-type humidifier.

You have a client who requires constant humidity level. The water quality is questionable, softened or RO. You have a client where lifetime cost may trump first cost. Use a resistive humidifier.

Hope this information helps you, the engineer or contractor, to make a better decision for your customer.

Check out the rest of the Commercial Electric Humidifier Series:

Part 1: Which Style of Commercial Electric Humidifiers Should I Choose?