How a centrifugal pump moves water may seem too basic for engineers and contractors to spend time reading about. However, understanding how a centrifugal pump works will help in proper selection and application as well as proper service and troubleshooting. We begin this series by examining how a centrifugal pump operates and the basic parts of these pumps.

Positive Displacement Pumps

A good way to begin the article is to talk about a different type of pump, the positive displacement pump. We do this because this is how most people think all pumps work. Most of us have used the pump shown above. If we have not used it, we have become a victim of it thanks to a brave 10-year-old.

We load the marshmallows into the “pump” and create pressure. When that pressure is released, the projectile is pumped out. Look out! Ouch!

A positive displacement pump works in a comparable manner. Our pump is grabbing a slug of water and some sort of pressure pushes the water out and into the pipe. If you block the outlet, the pressure builds. You may even break the pump if it continues to build pressure with a closed discharge.

Another type of positive displacement pump many have used. A centrifugal pump works in a much different way.

Centrifugal Force: A Simple Example

Well, if we are using a marshmallow gun for one pump, let’s use another fun thing for centrifugal pumps.

This ride shown above or a “round up” rise or graviton type ride all work on centrifugal force. On this ride, no one is pushing on the people to pin them to the fence. Centrifugal force is the action they are experiencing. The faster it turns, the more force the person experiences.

What would happen if the ride were going and somehow a person dropped into the center of the ride? Centrifugal force would push them to the fence again.

Imagine: what if the fence behind them broke? Centrifugal force would cause them to fly out of the ride.

If a person flew out of the ride and into a pipe that then flowed into the middle of the ride, centrifugal force would send them out again. If this person did this once a minute and their name was George, we would have a flow of 1 GPM or George per minute. (SOOOO SORRY 😊)

Centrifugal Pump Impellers

Now let’s look at centrifugal pumps. We will use a couple of figures from a Xylem, Bell & Gossett technical manual TEH-1166B.

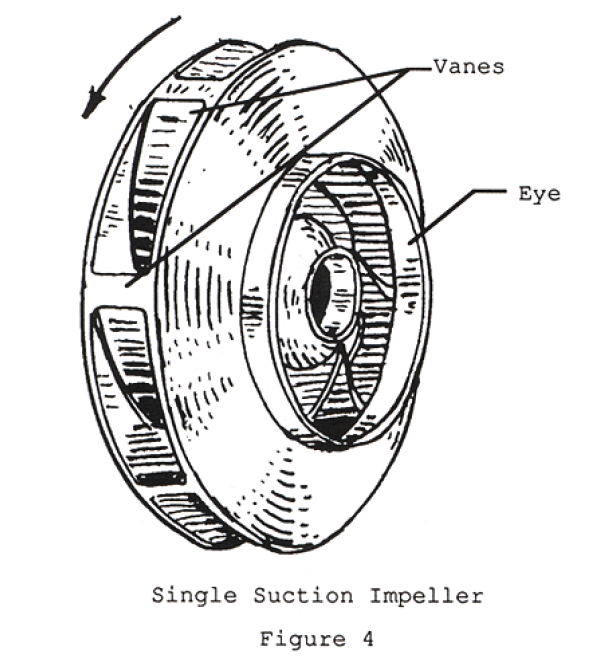

Here is a closed centrifugal pump impeller. Water is available at the inlet or eye of the impeller. The impeller is turning. The water moves from the eye to the outlet through vanes. It is important to note that the vanes are “slapping” the water, not digging into the water. Nothing is grabbing the water and physically pushing it. Centrifugal force is at work.

I invite you to study the TEH-1166B manual for more information.

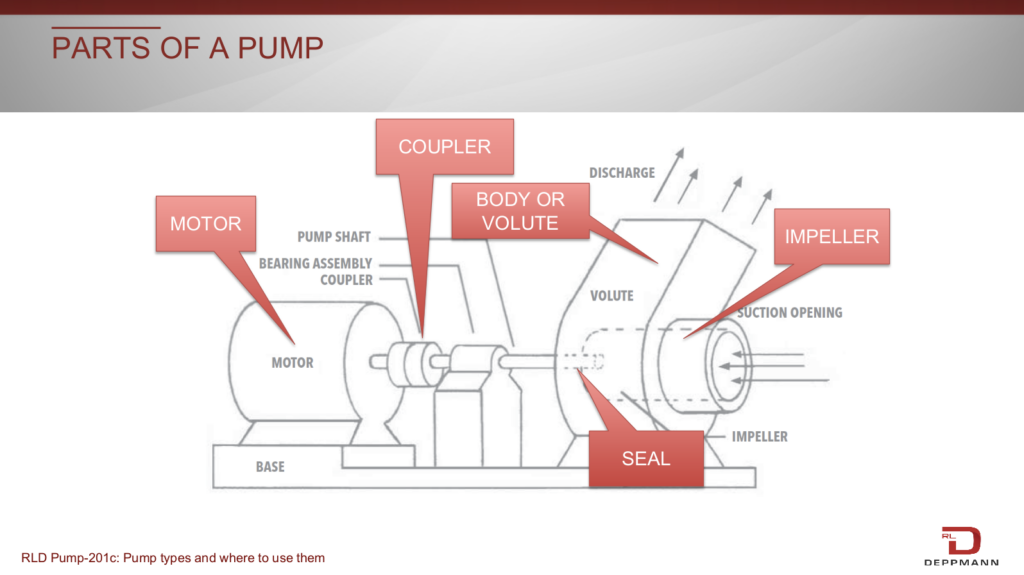

We used figure 3 from the B&G TEH-1166B manual as part of one of our seminars. The water leaves the impeller into the pump volute. The lowest pressure caused by the centrifugal action is the entrance to the eye of the impeller. This lower pressure is even lower than the pressure in the pipe attached to the pump inlet or suction connection. There is a pressure drop inside the pump.

The highest pressure is at the outlet of the impeller. There is a short distance from this point to the outlet or discharge of the pump.

The faster the impeller turns, the more discharge pressure created. The larger the impeller diameter, the more discharge pressure created. The “fatter” or wider the impeller is, coupled with a larger diameter eye, the more flow rate it can produce.

We will use these ideas when we talk about pump curves in the next R. L. Deppmann Monday Morning Minutes