We recently had an inquiry from an engineer who was concerned about pump operation compared with the submitted pump curve. It appeared from the balance report that the operation point was below the pump curve. When I looked at the report and the pump curve, I immediately started thinking about velocity head corrections. If you are a balance contractor or an engineer reviewing a balance report, you should understand when to be concerned about velocity head corrections and its effect on pump readout.

We recently had an inquiry from an engineer who was concerned about pump operation compared with the submitted pump curve. It appeared from the balance report that the operation point was below the pump curve. When I looked at the report and the pump curve, I immediately started thinking about velocity head corrections. If you are a balance contractor or an engineer reviewing a balance report, you should understand when to be concerned about velocity head corrections and its effect on pump readout.

The Effect of Velocity Passing an Orifice

When fluid in a pipe passes the port of a gauge connection, there is a venturi effect on the opening. Without attempting to go too far into the theory, I can give you a quick example many of you are familiar with. Look at the video above. The lawn fertilizer attachment on the hose is used to draw fertilizer out of the bottle and mix it with the water flowing through the hose.

The fertilizer is pulled up due to a vacuum caused by the velocity of the fluid passing the hole. This same science will cause an issue when reading out gauges in a hydronic system.

Velocity Head Correction when Reading a Gauge

The venturi effect described above causes a pull on the bourdon tube of the gauge. This pulls the needle lower than the actual pressure. The formula for the correction is:

Velocity head correction = (V² / 2g) feet.

Where “V” is the velocity in Feet per second (fps) and “g” is the gravitational force constant of 32.2 fps2

Let’s look at an example. Assume we have a 5” schedule 40 steel pipe with a flow rate of 1000 GPM. What is the velocity head correction? The velocity is 16.03 fps. The correction is (16.03 X 16.03/64.4 = 4 feet. A gauge reading 60 PSIG would normally be converted to feet by multiplying by 2.31. So, 60 PSIG = 138.6 feet. The velocity head correction would make it 138.6 feet plus 4 feet = 142.6 feet.

Using Velocity Head Corrections in Pump Readout

Gil Carlson, the author of much of the original Bell & Gossett Engineering Design Manual publications, used to say, “A difference to be a difference has to make a difference.” This holds true for pump readout velocity head corrections. The corrections are small, so they only make a difference with smaller pump heads or very high velocities. Let’s look at two examples:

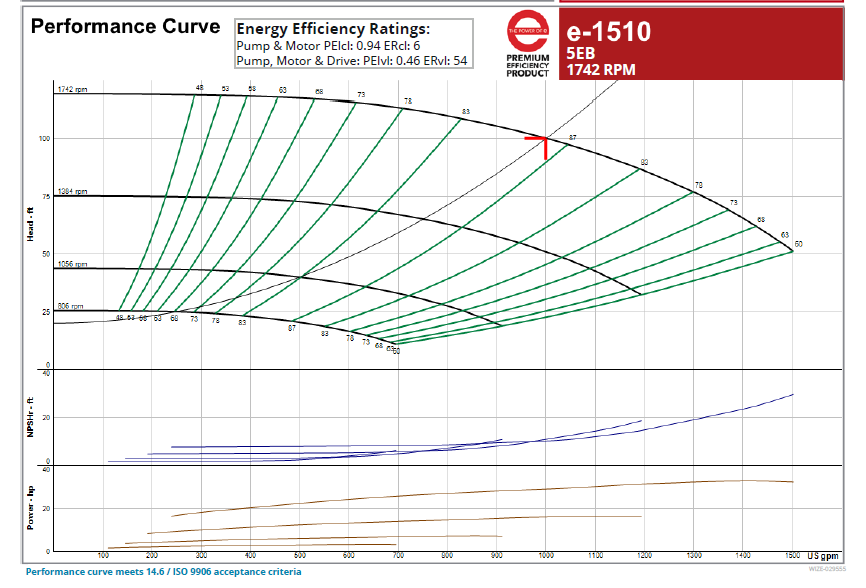

Example 1: B&G e1510-5BC, 1000 GPM at 100’

This pump has a 5” discharge and a 6” suction. The velocity head correction will be applied to both gauge readouts so it will not matter what the readout is. It will only matter what the velocity is. In other words, let’s assume the discharge reading is 60 PSIG and the suction reading is 16.3 PSIG. The difference of 60 PSIG minus the 16.7 PSIG is 43.3 PSIG X 2.31 = 100 feet.

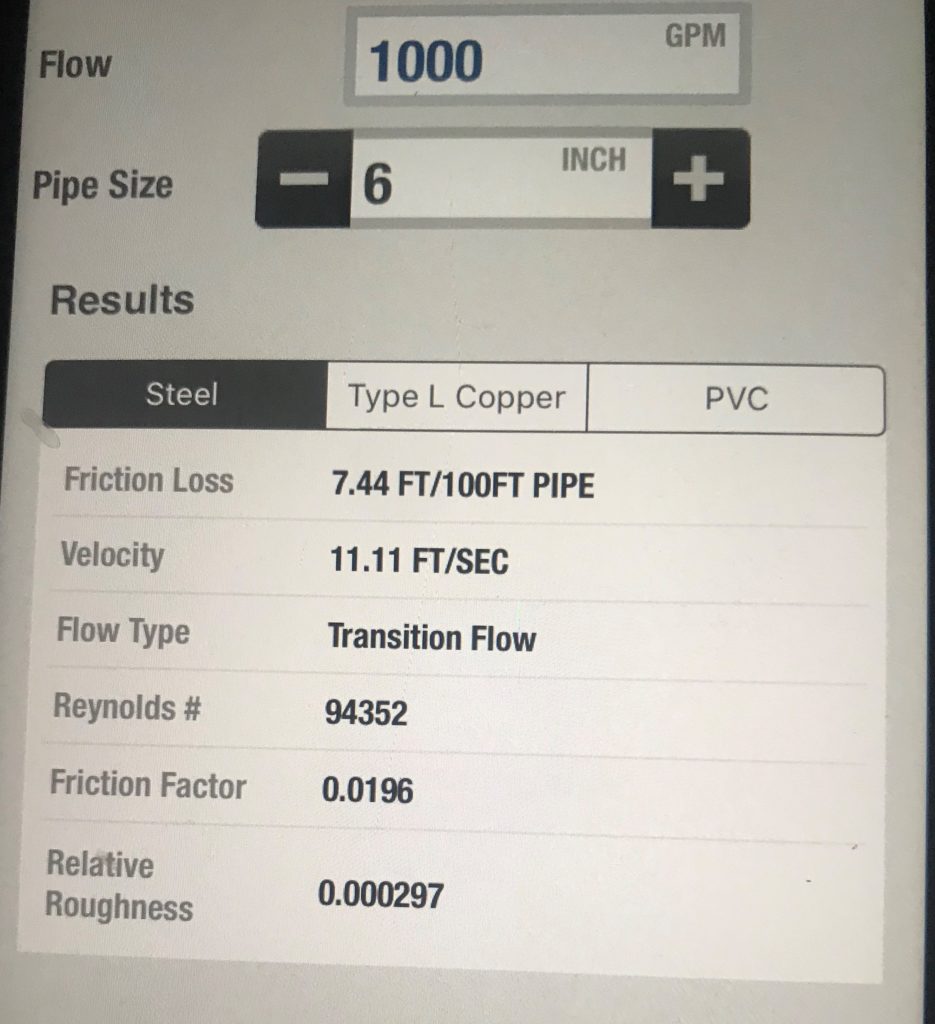

Let’s look at the correction. The Bell & Gossett electronic system syzer is a great tool for this. Here is a screenshot from the mobile version for both the 5” and 6” sizes.

The velocity head for the 6” pipe is (V2/2g) or (11.11 X 11.11)/64.2 = 1.92 or about 2 feet. The velocity head for the 5” was calculated earlier at 4 feet. The difference is 2 feet. Since the velocity pulls the readings down, we would add the difference of 2 feet back to the readout and the pump head would be 102 feet. The difference in the pump curve is so small that it does not make a difference.

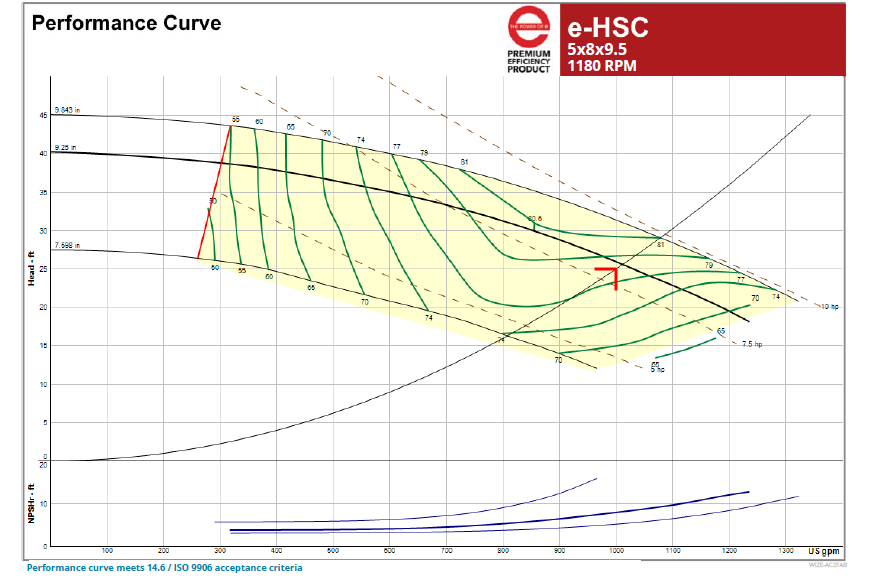

Example 2: B&G e-HSC -5x8x9.5 1000 GPM at 25’

I started the article with a troubled phone call, and this is the pumping scenario that caused the issue. I changed the pump to protect the innocent.

Here the velocity on the discharge is identical to the pump above but the suction velocity in 8” pipe is lower at 6.42 fps. The suction velocity head correction is (6.42 X 6.42)/64.4 = 0.6 feet. The correction is 4.0 feet minus 0.6 feet = 3.4 feet.

What happened on this job was the balance report said the chiller and the flow meter we sold, a Badger M2000 magnetic flow meter both indicated 900 GPM but the pump readout indicated we were at design. What was missing was the velocity head correction.

No, the sky is not falling! If you are a NEBB or AABC balance contractor or anyone reading out a device with different pipe sizes on the product or pipe just remember a couple of things. When the velocity is very high, review the velocity head correction for any change in your calculations. For pumps where the head reading will be low, remember to correctly apply the velocity head correction for an accurate analysis.