The minimum run time in a sump, effluent, or sewage pump is determined by the flow rate and the volume of water in the basin between the lead pump on float and the pumps off float. The minimum run time for these constant speed pumps will affect the basin depth and/or diameter required. What is the Bell & Gossett recommendation for minimum run time in these applications?

The minimum run time in a sump, effluent, or sewage pump is determined by the flow rate and the volume of water in the basin between the lead pump on float and the pumps off float. The minimum run time for these constant speed pumps will affect the basin depth and/or diameter required. What is the Bell & Gossett recommendation for minimum run time in these applications?

Sump Basin and Float Spacing Minimums

Floor space in mechanical equipment rooms of buildings is always critical. The sump basin diameter with the cover can occupy a large amount of space. The engineer will want to make the diameter of the basin as small as possible. The R. L. Deppmann Monday Morning Minutes blog Pump Guide Rail Assemblies and Sump Diameter defines suggested minimum basin diameters. In another blog, Sump & Sewage Applications: Choosing 3-Float vs. 4-Float Control we suggest the minimum spacing of floats to avoid entanglement. There is also information on our website at, Sump & Sewage. Knowing the minimums is important but the flow rate of the pump and the minimum run time will determine the maximum depth or basin diameter.

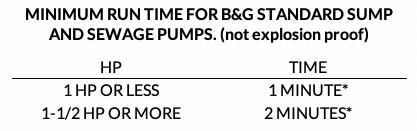

Minimum Run Times for Non-Explosion Proof Pumps

Explosion proof pumps have a separate set of concerns. The minimum run time for explosion proof pumps will be listed in the literature or available from the manufacturer. For the standard non-explosion proof pumps B&G recommends the following minimum run times.

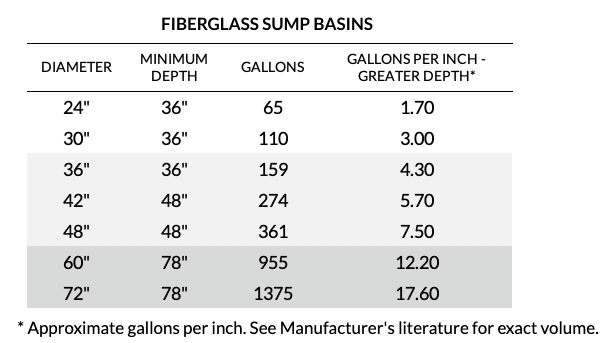

We know the time we want the pump to run, and we know the pump flow rate. The only thing left is the volume of water required between the floats. Here is a simple chart from our website, Sump & Sewage.

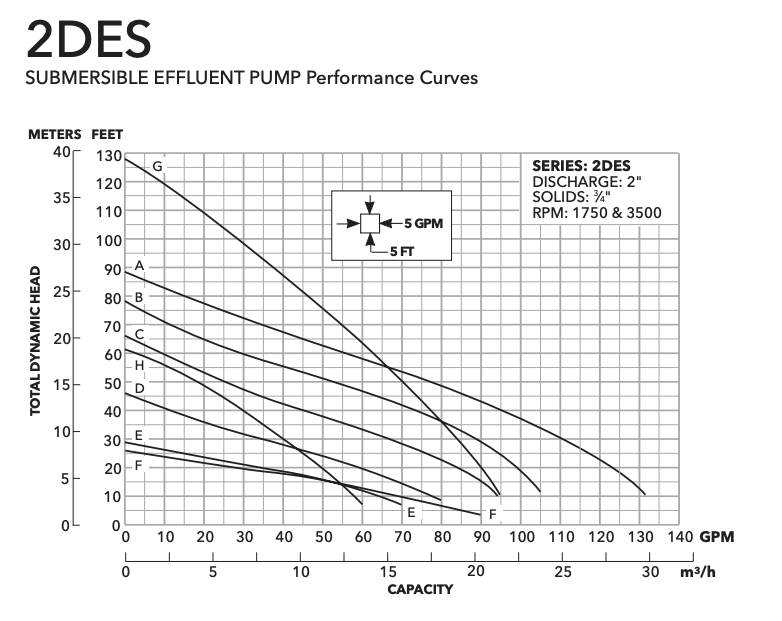

Here is a quick example: Assume you are designing a storm water sump pump system and you have determined you need to pump 50 GPM against 20 feet of head. You select a B&G 2DES series effluent pump with a ½ HP motor, since you only expect ¾” solids and want the advantage of dual seals, with moisture sensing, between the two seals. Your head selection is based on 3” pipe size, which is just above the minimum velocity of 2 FPS (see MMM Sump and Sewage Pumps – Discharge Line Size or our website). You could have also chosen 2” pipe with a 4.5 FPS velocity.

You want pump guide rails and based on the Monday Morning Minutes mentioned above or our website, you select the 48” diameter sump. The pump is ½ HP, so the minimum run time is 1 minute. From the chart above there is about 7-1/2 gallons per inch. 50/7.5 will round to a minimum of 7” between the lead pump on and the off floats.