| with edit by Norm Hall

Printer Friendly (PDF)

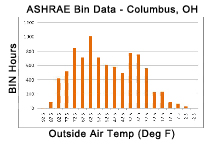

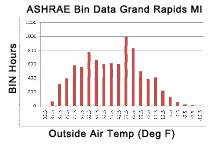

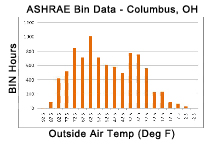

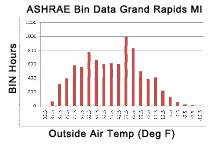

The last two weeks we defined turndown ratio and last week we introduced ASHRAE Bin data. Turndown ratio is defined as the ratio of the maximum input to the minimum input. It is an expression that translates to a minimum percentage of firing rate the appliance is designed to operate. The ability to modulate infinitely from the minimum to the maximum, translates to improved seasonal efficiency by being able to match the actual load requirements. A “Bin” data report identifies the amount of hours a specified location experiences varying outdoor temperatures for a given geographic area. Bin is a description of the temperature sampling size. Let’s look at two examples:

|

|

|

When you look at the modulating boiler options, this information will aid in the evaluation of your final selection. This information helps us to understand the amount of time that the system operates in the part load condition. Let’s use the Columbus, Ohio data in an example using two Laars NTH-850 NeoTherm condensing boilers. Each Laars NTH-850 has an input rating of 850,000 BTUH so two in parallel have 1,700,000 BTUH input. Since each one has a 5:1 turndown, the total system can turndown to 170,000 BTUH. (850,000 X 0.2 X 2). Looking at the chart above, we can determine the system operates above 10% load 93% of the time. Using the two Laars NTH-850 boiler is parallel allows us to modulate and avoid cycling costs 93% of the time!

In our second example, we will use the Grand Rapids data and two of the Aerco Benchmark BMK-2.0 boilers with a design input each of 2,000,000 BTUH and a 20:1 turndown ratio. In this case, the Aerco boilers provide a total of 4,000,000 BTUH input and can modulate from 4,000,000 BTUH down to 100,000 BTUH WITHOUT having to cycle off and on to match the part load condition. The Aerco Benchmark, with its 20:1 turndown, allows us to avoid cycling 99.5% of the season in our Grand Rapids example!

As we mentioned last week this cycling, in particular, short cycling can have dramatic effects on equipment, seasonal efficiency and carbon emissions.

• The equipment affects can include stress on the heat exchanger, resulting in premature failure, and (b) wear and tear on controls decreasing longevity.

• Seasonal efficiency is reduced by the extra cycles of pre-purge and post purge operation, wasting valuable heat to the atmosphere without return on investment.

• Carbon emissions (from start-up) are increased due to the temperature overshooting that short cycling causes.

Our two examples clearly state the case for the use of multiple boilers in parallel. The Laars example avoided cycling 93% of the time and the Aerco example 99.5% of the time.

For the design professional, who is seeking sustainable solutions to their clients concerns, look no further than the condensing products offered by Aerco and Laars and represented by the R. L. Deppmann Company. |

|