| Printer Friendly (PDF)

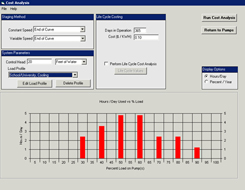

The last two weeks we used the Pump Affinity Laws and the ITT Bell and Gossett System Syzer® to either trim the impeller or reduce the speed in an oversized pump. Once we solve the over sizing problem, another issue may need to be resolved. Often times in older systems and occasionally today, someone throttles the discharge valve rather than trim the impeller. It gets us back to the design condition of 3500 GPM at 140 feet and it is relatively easy to do. However, when we do this, we waste energy. The cost implication can be unbelievable! I used the ESP-PLUS® program from B&G and determined the operating cost of our trimmed impeller variable speed pump with a 20 foot control head to be about $17,000.00 per year I used the same program to approximate the cost of a throttled discharge valve with the 60 feet across it and it added $9,000.00 to the annual operating cost!

If the pump was oversized just 30 feet instead of 60 feet and the valve was throttled it would cost $4,000.00 more. What about just 10 feet: 10 feet can’t be that much, right? In this variable speed application that extra 10 feet of head will cost you $1,600.00 per year. What happens if the throttled discharge is on a constant speed pump such as a condenser water application? These numbers all become much larger. For our customers in Michigan and Northern Ohio: Contact Dave Taptich or Dale Zuehlk at RL Deppmann to schedule a service visit for analysis of your pumping system costs and start putting those wasted operating dollars back in your company’s pockets. |

|

Disclaimer: R. L. Deppmann and it’s affiliates can not be held liable for issues caused by use of the information on this page. While the information comes from many years of experience and can be a valuable tool, it may not take into account special circumstances in your system and we therefore can not take responsibility for actions that result from this information. Please feel free to contact us if you do have any questions.

Archives – Click here for Past Articles