| Printer Friendly (PDF)

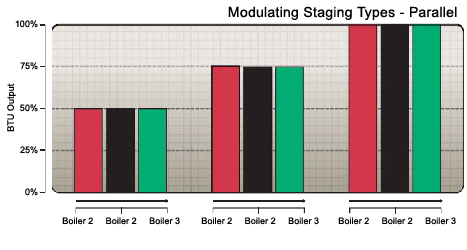

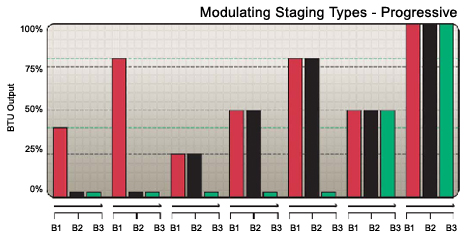

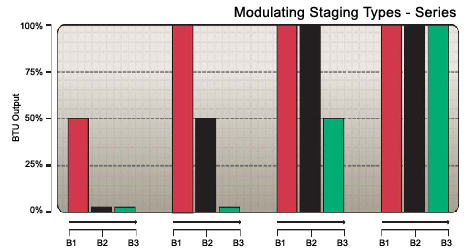

Most Boiler manufacturers sell and market their own stand alone boiler control. Many will permanently install controls within the boiler cabinet or provide a wall mount controller. To keep costs down, they typically will make assumption on how you want to control your boilers. They typically will provide either “Parallel” modulation or “Progressive” modulation. Few offer the “Series” modulation option. Lets take a look at the differences. 1) Parallel operation is the simplest modulating algorithm. All boilers will modulate from the starting position together. You typically have the ability to adjust the “start point”, or the percent that the boilers will begin, and then all boilers will fire at the same rate, from this start point to 100%. Different controllers can control different numbers of boilers with this option. The HBX CPU-1000, for example, can handle up to five boilers in parallel operation. When modulating down to a no load condition, all boilers will cycle down to the “start” position, then a PID calculation will allow all boilers but one to drop off for a calculated period to help minimize potential short cycling. See graph below. 2) Progressive Modulation is a combination of Series and Parallel. The lead boiler will start, and modulate up to something less than 100% (i.e. 80%). Once the lead boiler hits 80%, the second boiler will fire to 40% and the lead boiler will decrease to 40%. As the load increases, both boilers will increase up to 80%. Once these two boilers hit 80%, the third boiler will start and modulate up to approximately 55%, and the first two boilers will modulate down to approximately 55%. As the load increases, these three boilers will modulate up to 100% together. As load decreases, the process reverses. See graph below. 3) Series Modulation is typically not offered with many controllers. This is a very simple and basic, but effective algorithm. The lead boiler starts and ramps up to 100% fire. The the heat demand is not satisfied, then the lead boiler holds at 100%, and the second boiler starts to fire, ramping up until heat demand is satisfied. In this mod, the lead boiler could be at 100% while the second boiler could be at 43%. Once the second boiler is at 100%, it will hold at 100% as more boilers are brought online in a fashion similar to the second boiler. The process of modulating boilers off works the same, but in reverse. As in all cases, a PID calculation will control the lead boiler to minimize cycles. The HBX Control Systems Model CPU 1000 offers the choice of these three modulation options. The CPU-1000 design also allows for the addition of zone and pump modules for easy adaption to your existing or future design needs. |

|

Thank you for using products sold by R. L. Deppmann Company in Michigan and Ohio!

Disclaimer: R. L. Deppmann and it’s affiliates can not be held liable for issues caused by use of the information on this page. While the information comes from many years of experience and can be a valuable tool, it may not take into account special circumstances in your system and we therefore can not take responsibility for actions that result from this information. Please feel free to contact us if you do have any questions.

Archives – Click here for Past Articles