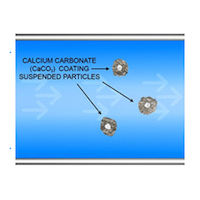

In this Monday morning minute, we will discuss the technology and effect that pulse technology via the Griswold Wave product provides specific to mineral scale prevention. Scale normally results from naturally occurring minerals that are dissolved in the water. In a cooling tower application, these minerals are concentrated by evaporation. When concentrated or heated, some of the minerals do not stay in solution and precipitate forming a surface deposit known as scale. This is the white deposit you might see inside a tea pot that boils hot water. The Wave™ Driver generates complex AC signals and DC pulses that are applied to the water via a series of four induction coils housed in a weatherproof Reaction Chamber. The induced electrical reaction zones create “seed crystals” in the flowing water. These crystals provide preferential sites for additional solids precipitation, thus protecting the heat transfer surfaces from scale deposits. Without the Wave™ scale forms on equipment surfaces as pressure mounts when evaporation causes minerals in the water to reach the point of saturation. The Wave™ removes the surface charge on the tiny solid particles in cooling tower makeup and re-circulating water. Those activated particles become favored sites for this pressure relief. The particles are flowing with the water so do not have to overcome velocity and they are closer to the minerals than to the sides of the equipment. These particles turn into non-adherent powder. This powder then settles harmlessly in the tower basin or is removed by filtration. By controlling scale, we are able to protect piping, chillers, heat exchangers and reduce energy requirements by increasing efficiencies of operation. The patented Wave™ Electronic Water Treatment system is advancing the science of sustainable water treatment. While outperforming competitors’ models, the Wave™ is quickly becoming the “green” standard for smart businesses. The future of Physical Water Treatment is here. Next week we will continue looking at how pulse technology controls bacteria, biofilm and legionella.

Without the Wave™ scale forms on equipment surfaces as pressure mounts when evaporation causes minerals in the water to reach the point of saturation. The Wave™ removes the surface charge on the tiny solid particles in cooling tower makeup and re-circulating water. Those activated particles become favored sites for this pressure relief. The particles are flowing with the water so do not have to overcome velocity and they are closer to the minerals than to the sides of the equipment. These particles turn into non-adherent powder. This powder then settles harmlessly in the tower basin or is removed by filtration. By controlling scale, we are able to protect piping, chillers, heat exchangers and reduce energy requirements by increasing efficiencies of operation. The patented Wave™ Electronic Water Treatment system is advancing the science of sustainable water treatment. While outperforming competitors’ models, the Wave™ is quickly becoming the “green” standard for smart businesses. The future of Physical Water Treatment is here. Next week we will continue looking at how pulse technology controls bacteria, biofilm and legionella.

Disclaimer: R. L. Deppmann and it’s affiliates can not be held liable for issues caused by use of the information on this page. While the information comes from many years of experience and can be a valuable tool, it may not take into account special circumstances in your system and we therefore can not take responsibility for actions that result from this information. Please feel free to contact us if you do have any questions.

| The objective of water treatment is to:

PREVENT MINERAL SCALE*, Control Bacteria, Biofilm And Legionella, & Inhibit Corrosion |