The last R L Deppmann Monday Morning Minutes described the recommended limitations when over speeding a HVAC pump with a Variable Frequency Drive (VFD). Today we will show how valuable this can be in the selection and specification of HVAC centrifugal pumps.

Pump Selection Fear – Short of Capacity

One of the great fears of the consulting engineer is under sizing the hydronic pump head. Pump affinity laws, BTUH coil heat transfer calculations, and ASHRAE flow tolerance recommendations all tell us that a slight miss on the pump head may result in a small difference in satisfying the system load. Knowing that, we still have a fear of a balance report coming in which tells the owner they are short of any flow rate compared with the schedule.

There are many examples of specifications instructing the reader to select a pump at less than the maximum impeller so the designer has “room to move” if needed. Most of these hand-me-down statements create a lot of confusion and often the actual pump selected and scheduled does not meet its own specification.

In addition, by not selecting a pump at or close to the maximum impeller published, you are giving up the possible best efficiency point (BEP) of the pump. How can you protect yourself while taking advantage of the efficiency gained at greater impeller diameters? Use the option of running the pump at a higher speed and hertz also known as over speeding a pump using a VFD.

Pump Selection Higher Speed Using a Variable Frequency Drive

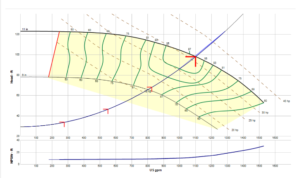

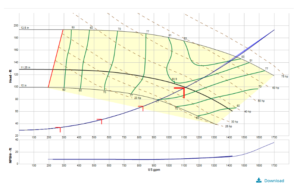

Look at the two selections below. The selection on the top is the better selection but many would choose to schedule the one on the bottom so they can increase the impeller if they need to. But, there is more to the story….

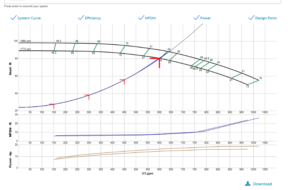

If I need to increase the impeller so the flowrate increases by 5%, I will run out of horsepower and have to increase from 40 HP to 50 HP. What about the better curve on the bottom? Let’s use the information provided in last week’s R L Deppmann Monday Morning Minutes on over speeding HVAC Pumps & Motors. If I increase the speed of the pump by 5% or up to 63 Hz. the e1510-5EB curve will now look like this (below).

The horsepower of the pump and the amp draw of the variable frequency drive (VFD) will be acceptable to operate this pump at 1860 RPM. This gives 10% additional future head capacity while still enjoying the higher efficient pump selection. I checked the horsepower and it is non-overloading all the way to 1450 GPM at the 1860 RPM higher speed. Let’s use this great pump!

Pump Specification Suggestion for Future Operation of a HVAC pump at a higher speed using a VFD

I might suggest removing all specification statements that say things like, “85% of maximum impeller” or “capable of increasing the impeller one diameter” or “pump selected for future larger impeller”. Instead why not try adding this to your specification:

“Pump and Motor shall have the ability to operate at 5% over the scheduled speed using a VFD without affecting the warranty or causing damage to the pump or motor.”

The one caveat here is that your selection should have enough horsepower to operate at the point created at the new speed should you need it. Interesting that for decades I have seen specifications indicating a need for potentially increasing the impeller with no thought about what the horsepower and frame size requirement would be in order to accomplish. Remember that changing an impeller might change the motor horsepower and may also change the pump shaft size, the bearings, the base and even the pump dimensions. Just make sure you have enough horsepower in your selections if you are using the suggested specification addition.

We will wrap up this pump selection series of the R. L. Deppmann Monday Morning Minutes next week.

Read the Entire How to Pick an HVAC Centrifugal Pump series:

- Part 1: Designing for Owner Satisfaction

- Part 2: Types of Pumps and Seismic Considerations

- Part 3: Mechanical Room Space & Type of Pump Selected

- Part 4: Pump Coupling Types — Close, Split or Flexible Coupled?

- Part 5: Choosing a Single or Double Suction Pump

- Part 6: Internally Vs. Externally Flushed Mechanical Seals

- Part 7: Mechanical Seal Materials

- Part 8: Motors for HVAC Centrifugal Pumps (Continued)

- Part 9: Over speeding HVAC Pumps & Motors

- Part 11: Best Practices for Safety and Performance