The last R L Deppmann Monday Morning Minute briefly defined the differences between inline and base mounted pumps. When the engineer or contractor is selecting the type of pump to use, available space is one of the criteria. This week we will look at the mechanical room space required by base mounted inline pumps and base mounted end suction pumps.

It’s easy to become fixated on floor space when designing a hydronic system. After all, space often equates to money in construction; a fact that can leave mechanical engineers starved for mechanical space. This is what makes the idea of pipe-supported, inline pumps so attractive, and even popular. Sometimes the choice is fine, other times it is not. For long term satisfaction and serviceability, there are a few things an engineer must consider before deciding to get that pump off the floor and in the air and (theoretically) out of the way.

How Large is the Base Mounted Pump?

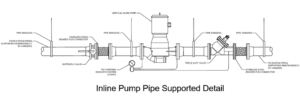

Small inline or booster pumps do take up less space than base mounted pumps of similar capacities. They are traditionally pipe supported and can be installed without taking up any actual floor space as shown here:

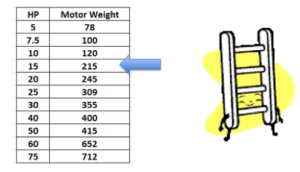

This works fine, assuming the pump and motor isn’t too large and the pump isn’t installed so high and/or in a space where servicing becomes difficult or even dangerous. Remember that the piping supports must be designed for the extra weight of not only the pump but the pump accessories ( e.g. the triple duty check and balance valve). Seismic concerns, if there are any, complicates matters even further. For these reasons, we recommend installing inline pumps that are 15 HP or larger on the floor. Notice the increase in motor weight in the chart below when the horsepower changes from 10 to 15.

What kind of service area is needed around the HVAC Centrifugal Pump?

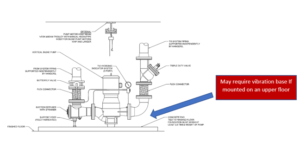

Clearly, it’s important that there be no obstructions to servicing the pump whether it is in the air or on the floor. If the inline pump is installed on the floor, keep in mind it will have to be installed with a suction diffuser or long radius elbow, 5 pipe diameters of straight pipe, and a discharge elbow which will increase the amount of floor space required on both the suction and discharge side of the pump. (See Below)

In a case like this, we would most likely recommend considering an end-suction or vertical double suction base mounted pump in lieu of the vertical floor mounted inline pump. An end-suction base mounted pump eliminates the need for the discharge elbow; a B&G VSX-VSC vertical split case double suction pump eliminates both the discharge elbow and suction diffuser. Plus, either base mounted pump can be serviced without having to remove the motor.

As the below graphic illustrates, the base mounted pumps can actually take up less space, especially when maintenance space allowance is taken into consideration.

Will multiple HVAC centrifugal pumps be piped in parallel with N+1 standby?

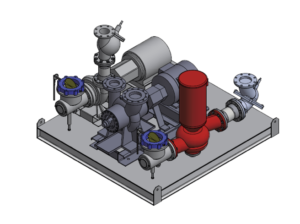

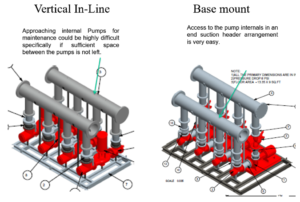

If more than two pumps are to be piped in parallel, we would again recommend base mounted for motor serviceability. As you can see by the image of the vertical inline pumps shown here below on the left, there is very little room to service either of the interior pumps. However, the B&G e1510 base mounted pump arrangement shown on the right provides access to all the pump internals from the back end of the skid.

Check out the next article in the series, Part 4 to learn about pump coupling types.

You can read the entire How to Pick an HVAC Centrifugal Pump series:

- Part 1: Designing for Owner Satisfaction

- Part 2: Types of Pumps and Seismic Considerations

- Part 4: Pump Coupling Types — Close, Split or Flexible Coupled?

- Part 5: Choosing a Single or Double Suction Pump

- Part 6: Internally Vs. Externally Flushed Mechanical Seals

- Part 7: Mechanical Seal Materials

- Part 8: Motors for HVAC Centrifugal Pumps (Continued)

- Part 9: Over speeding HVAC Pumps & Motors

- Part 10: Over Speed an HVAC Pump using a VFD

- Part 11: Best Practices for Safety and Performance