ASHRAE and the U.S. DOE both make definitive statements that water heater cycling can significantly affect efficiency. Today, we’ll quantify the energy loss from water heater cycling in volume and tankless models.In last week’s Monday Morning Minutes (MMM) post, I looked at the efficiency differences between volume water heaters and tankless designs due to return water temperature. Today we examine cycling.

What Is Water Heater Cycling?

Water heater cycling is the turning on and off of water heaters many times over short durations. It wastes energy and can affect the life of the water heater. A cycle starts when the temperature sensor closes the contacts to start the heater. This initiates a pre-purge, or starting of the fan without any gas. The purpose is to push any combustibles out of the heat exchanger before ignition. It normally lasts 30 to 40 seconds. Next the primary circulating pump is started and the burner ignites and the gas flows. Once the temperature sensor is satisfied, the heater goes into post-purge. This is again a small amount of time when the fan runs without the burner active.

This process is a cycle. Each time there is a cycle, the pre-purge and post-purge brings cold air in that lowers the temperature of the metals, which must be reheated. There is also the energy of the fan operating during that time.

When Does Cycling Occur?

Cycling occurs when the demand load on the heater is less than the minimum firing rate of the water heater. In other words, if the BTUH required to bring the water temperature up to the set point is less than the minimum BTUH that the water heater can operate at, the heater will keep turning on and off.

We all experience this when we’re stuck in traffic. If we keep the car in a higher gear, we have to keep hitting the brakes and start and stop. To resolve this, we drop to first gear. Some water heaters can’t operate in first gear. We call this turndown.

Turndown Makes a Difference

Aerco manufacturers the Innovation with a turndown as high as 20:1. Many volume water heaters have a 5:1 or 3:1 turndown ratio. This means that, for example, an 850,000 BTUH water heater with a 5:1 turndown can operate down to 170,000 BTUH—below that, it cycles on and off. This low capacity cycling can occur under low loads and even no-load periods due to the recirculating system.

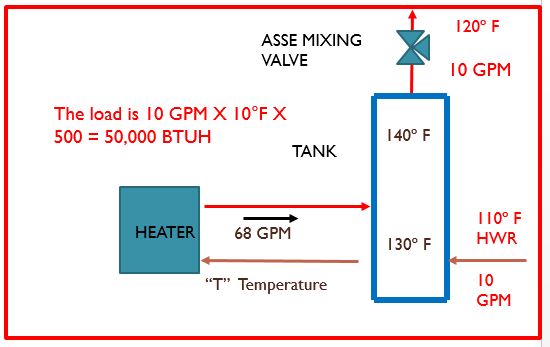

Commercial and institutional systems normally use recirculating systems to keep hot water available quickly at the fixtures. These recirculating systems return water to the storage tank with 10 to 20 degree drop from the supply temperature. This lower temperature water mixes in the tank and will eventually reduce the temperature enough to start the heater. Let’s look at an example.

Here we see a typical system with a 50,000 BTUH recirculation load. Let’s assume the water heater is 90% efficient and is rated 850,000 BTUH with a 5:1 turndown. That means the lowest firing rate is 170,000 BTUH X .9 = 153,000 BTUH. So the water heater will cycle (153,000/50,000 ≈) 3 times per hour. As the recirculating load is lower, the number of cycles increases. It will take a flow of almost 3 GPM from the tank in addition to the recirculation load to avoid cycling.

How Much Energy Do I Lose to Cycling?

We all understand that water heater cycling wastes energy. The question is how much energy.

Let’s continue with the example above. An 850,000 BTUH water heater could weigh about 500 lbs. Most of that weight is the heat exchanger. We could estimate that 60% or 300 lbs. of the weight is the heat exchanger. During pre-purge and post-purge, we introduce cold air, which lowers the heat of the metal. In Michigan and northern Ohio, the average outside temperature for the year is 48°F. If the heater was off and the heat exchanger was copper, the metal would cool to the water temperature of 140°F or even lower. The specific heat of copper is 0.09. The pre-purge and post-purge cycles each use .09 X (140-48) X 300 lbs. = 2,484 BTU. The total cycle would be 4,968 BTU, and if we cycle three times per hour, we lose 14,904 BTUH. This loss represents 2% of the 850,000 BTUH 90% efficient heater.

If we couple this with the efficiency numbers from last week’s MMM and include the energy of the tank and heater pump, the total energy penalty for volume water storage over tankless designs could be 7.6% to 10.6% year-in and year-out.

What is the cost to save this energy with tankless design? Visit the R. L. Deppmann Monday Morning Minutes next week.