Last week, we introduced this four-part series Essential Water Quality Management to Safeguard Health and Infrastructure. In the second installment of this series, we will look more closely at the role water treatment plays in occupant health and the unintended consequences of chemical disinfection.

Last week, we introduced this four-part series Essential Water Quality Management to Safeguard Health and Infrastructure. In the second installment of this series, we will look more closely at the role water treatment plays in occupant health and the unintended consequences of chemical disinfection.

Chemical disinfectants such as chlorine are used to mitigate the risk of waterborne disease and illness. Chlorine has been added to drinking water for over 100 years to prevent diseases such as typhoid fever, cholera, and dysentery. It is also used to decontaminate systems when Legionella growth is suspected or confirmed. However, chlorine and other disinfectants react with natural organic matter to form disinfection byproducts which can be hazardous to human health.

Health Risks of Disinfection Byproducts

Disinfection byproducts are regulated by EPA under the Disinfectants and Disinfection Byproducts Rules (DBPRs). These rules apply to community water systems and non-transient non-community water systems that add a disinfectant to the drinking water. Two of the most common DBPs are trihalomethanes and haloacetic acids which studies have shown that long-term exposure to consistent levels of THMs or HAAs may increase cancer risk and cause problems with the liver, kidney, and CNS system.

Regulatory Standards and Limits

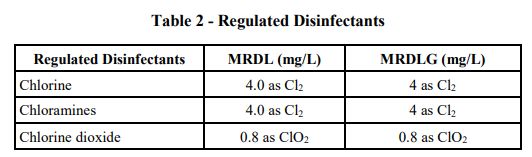

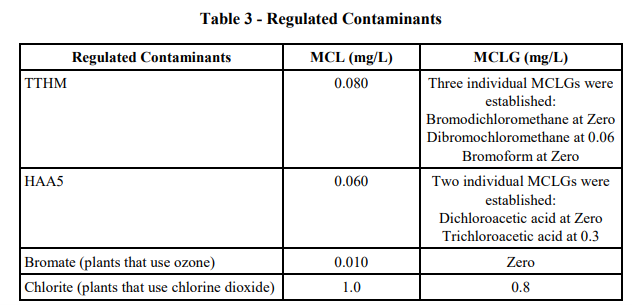

Under the Safe Drinking Water Act, EPA established maximum residual disinfectant levels (MRDLs) for chlorine, chloramines, and chlorine dioxide, and MCLs for DBPs including chlorite, bromate, TTHM, and HAA5.

Standards and Contributing Factors

ANSI/ASHRAE 514 classifies disinfection byproducts as a type of chemical hazard and unintended consequence of chemical disinfection. The standard lists the DBP associated with the type of disinfectant with its relative cancer risk.

DBP formation is influenced by concentrations of organic matter, water temperature, and pH. The risk of DBP formation in systems using surface water is higher due to the presence or more naturally organic matter compared with groundwater.

Engineering Considerations

Engineers should consider the unintended consequences of chemical treatment during design and evaluate methods such as filtration to reduce the concentrations of natural organic matter. The less organics, the less biofilm that forms on piping surfaces. It’s much easier to prevent biofilm formation than to have to remove it. Other considerations include:

- Reduce the contact time and/or the concentration of the disinfectant

- Ensure turnover of storage tanks and eliminate areas of stagnant water.

- Reduce the “water age” (the length of time water is in the distribution system).

- Change the location where the disinfectant is added

Next week we will continue the series with a discussion on the importance of water quality management in protecting your HVAC equipment assets.

Previous Articles in This Series:

This series is written in partnership with the Water Solutions Group (WSG). WSG offers innovative water quality solutions. Contact the team for a site assessment or view our extensive line card to learn more.

Water Solutions Group is a separate division of the R.L. Deppmann Company created to provide end users and engineers with a valuable resource in efforts to improve water quality. Proper water quality management protects the equipment, operations, occupants, and environment. Water quality should be considered at the time of design to ensure safe and efficient operating systems. Our intimate knowledge of water systems positions Water Solutions Group to be the ideal partner when evaluating operational issues that may arise because of poor water quality.