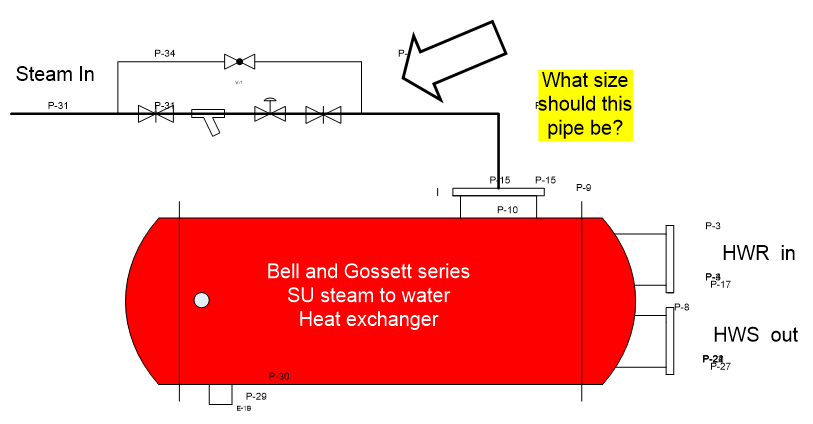

Many institutional and industrial projects use steam to heat the water for hydronic heating, domestic water, or processes. The pipe size prior to the steam control valve is often shown, but the pipe size from the control valve to the steam-to-water heat exchanger or converter is rarely shown. A question we receive is, “What is the right steam inlet pipe size, after the control valve entering the heat exchanger?”

Determining the Proper Steam Inlet Pipe Size

Bell and Gossett engineers suggest the steam inlet pipe size entering a steam-to-water SU heat exchanger be limited or sized to avoid steam impingement on the horizontal copper tubes inside the exchanger. The opening size on our heat exchangers is sized for the steam pressure and PPH load. Therefore, the minimum pipe size entering the heat exchanger should be equal to the heat exchanger shell size steam connection.

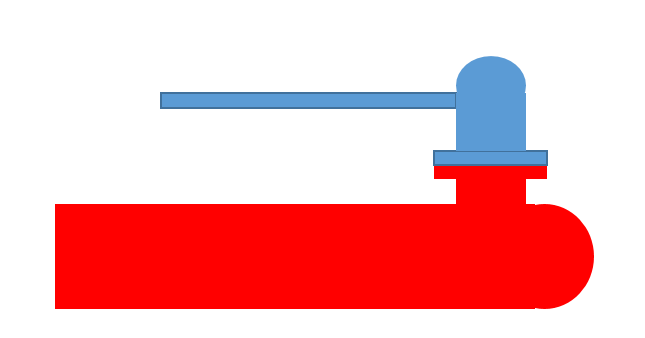

Industrial applications often use steam pipe sizing with very high velocities. When that occurs, the piping transition to match the size of the heat exchanger steam connection may be difficult. One possible piping method is represented here:

What If the Opening Size Isn’t Known?

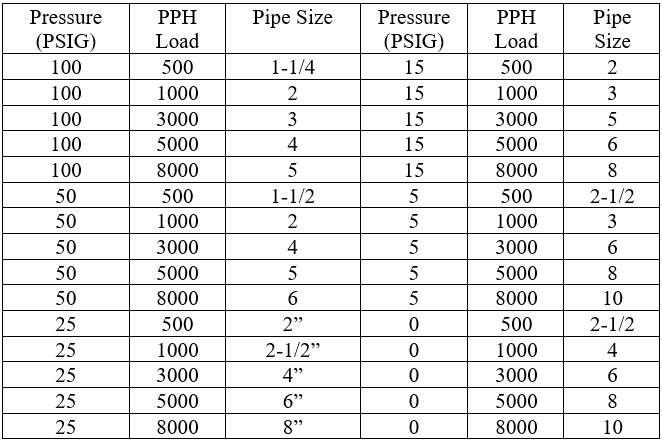

When the opening size isn’t known, R. L. Deppmann uses a ‘rule of thumb’. Size the pipe for 5000 FPM for steam pressures from 60 to 125 PSIG, and 6000 FPM for pressures under 60 PSIG. See the quick selection chart below for low pressure steam applications.

Thank you for using products sold by R. L. Deppmann Company in Michigan and Ohio! Next week the Monday Morning Minutes will look at the condensate piping on a steam-to-water heat exchanger.