Over the last several weeks we discussed the feared NPSH and showed it is rarely an issue at design conditions. More often than not, noise and pressure problems are caused by air in the suction piping system. The suction pipe, in many cooling pumping systems, is under very little pressure. In fact, the suction of the pump could be under a vacuum.

AIR WILL NOT VENT FROM A VACUUM TO ATMOSPHERE!

Bell and Gossett has several piping rule suggestions for cooling tower pump suctions.

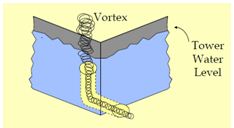

RECOMMENDATION #1: Always specify an anti-vortex baffle, sometimes called a doghouse, in the tower outlets.

Towers normally have very low storage heights of water in the basin. Any vortex that starts will reduce the flow rate and pull air into the piping system.

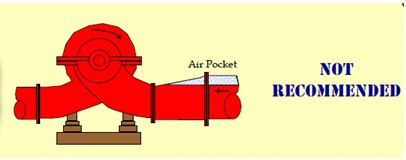

RECOMMENDATION #2: Avoid air traps caused by elevation changes in the suction pipe. Elbows used to go up & over pipe or obstacles cause an air trap. The improper use of a reducer at the pump flange can have the same effect.

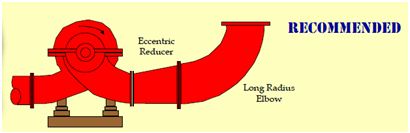

RECOMMENDATION #3: When needed, use eccentric reducers at the pump suction. The orientation depends on where the suction pipe is located.

In both examples, we avoid trapping air while transitioning pipe sizes.

Next week we will continue to look at cooling tower pump suctions.

Disclaimer: R. L. Deppmann and it’s affiliates can not be held liable for issues caused by use of the information on this page. While the information comes from many years of experience and can be a valuable tool, it may not take into account special circumstances in your system and we therefore can not take responsibility for actions that result from this information. Please feel free to contact us if you do have any questions.