HVAC variable speed pump control does not have to be complicated. Often times a simple differential pressure sensor (DP) at the farthest point from the mechanical equipment room set at 10 PSIG will do the trick. Then, if the owner complains about comfort issues, the construction team just raises the set point until the problem goes away. As the problem goes away, so does the potential energy savings for the owner. If we want the pumping system to operate correctly, save the most energy, and provide comfort, we need to address system diversity early in the design.

HVAC variable speed pump control does not have to be complicated. Often times a simple differential pressure sensor (DP) at the farthest point from the mechanical equipment room set at 10 PSIG will do the trick. Then, if the owner complains about comfort issues, the construction team just raises the set point until the problem goes away. As the problem goes away, so does the potential energy savings for the owner. If we want the pumping system to operate correctly, save the most energy, and provide comfort, we need to address system diversity early in the design.

Variable speed pump control choices are all about diversity.

What is HVAC System Diversity?

We understand “diversity” as a good thing in life, work, and opinions. Diversity in HVAC systems is normal, but diversity in pumping systems will require some good old fashioned reasoning.

Let’s think of a chilled water cooling system in a high school. If two classroom are next to each other and one is occupied and the other is not, there will be diversity of cooling load between the two rooms. The control valve in each will operate at different positions to satisfy both conditions. This should not affect the design of the pumping system control choice.

If the sun rises in the east and sets in the west, the load at design conditions will shift. The severity depends on the amount of glass and orientation of the school classrooms. This may affect the design of the pumping system control choice.

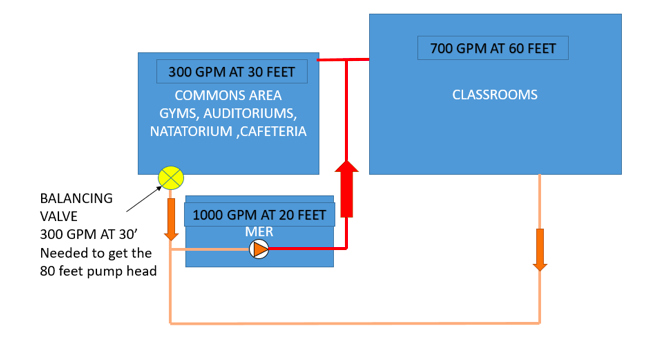

The commons area, gymnasiums, auditoriums, and dining areas have a severe amount of diversity. This will affect the design of the pumping system control choice.

Required Variable Speed Pump Flow with Load Diversity

The beauty of diversity in hydronic systems is the total pump flow rate and production source does not have to match the total of all terminal units. Some terminal units are expected to be at a much lower output when others are near design conditions. That said, most systems have pump flow rates which equal the connected terminal units.

In the high school example above it is easy to understand this load diversity. During the day there are close to 2000 students in the classrooms with very few of them in the auditorium or gyms. At night during an event, there could be close to 1000 people in the auditorium and gyms with no one in the classrooms.

With the diversity of load comes the diversity of pumping flow rate. Let’s look at an example.

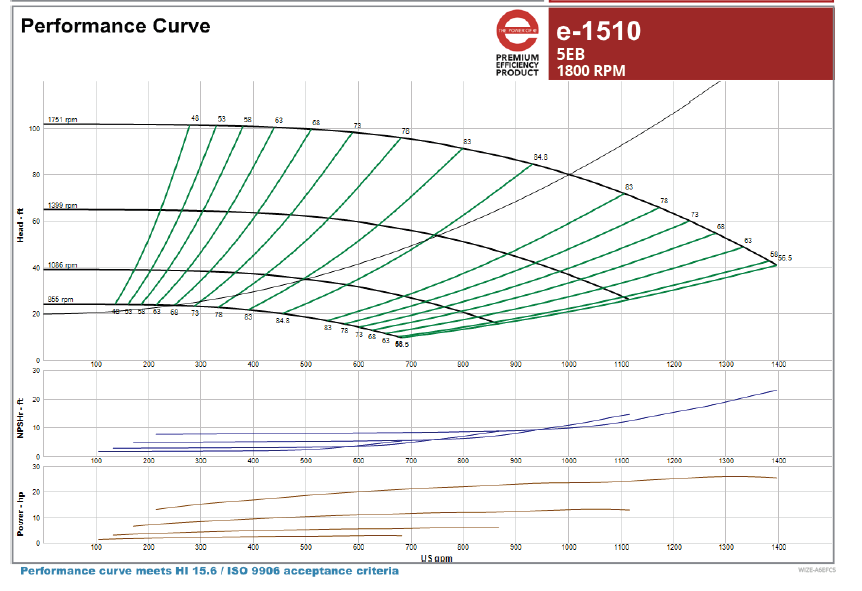

Example: A fictional high school in Grand Rapids, Michigan. Total chilled water capacity of 1000 GPM. Primary variable pumping system. The pumping system has one operating variable speed pump with a 100% standby. Capacity of the pump is 1000 GPM at 80 feet at design.

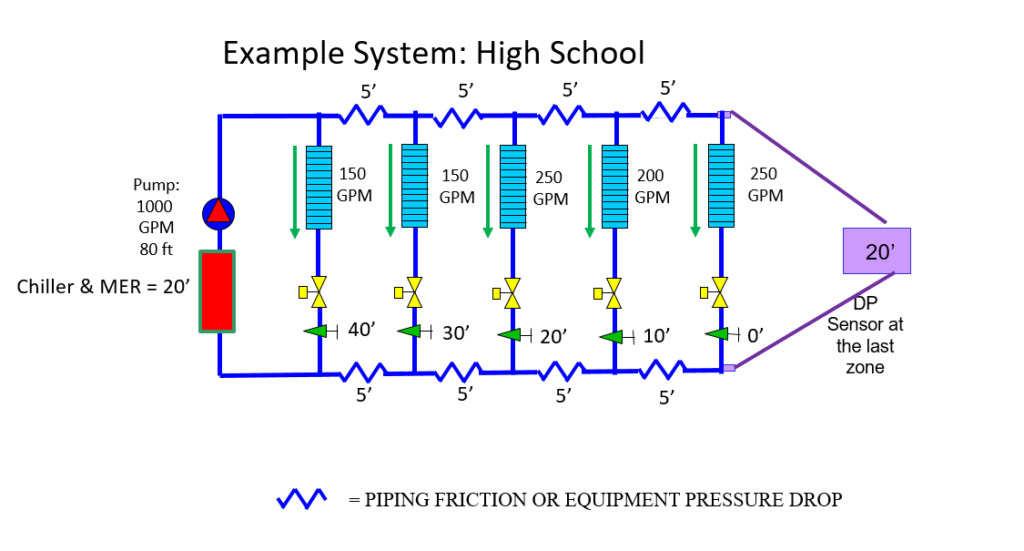

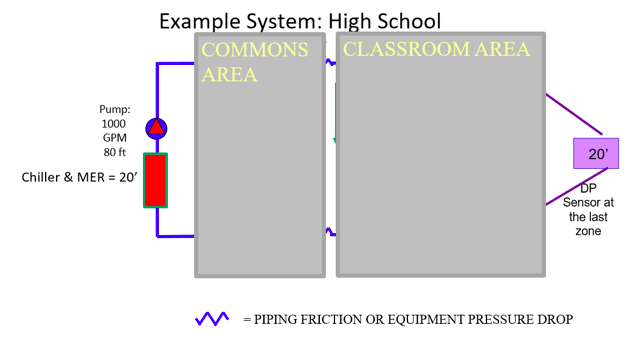

We could draw the system in a ladder block diagram to look like the following.

If we create a representation of the fictional system as a ladder diagram and include the balancing valves and zones, it would look like this. Our pump head at 1000 GPM is 80’ (20’ for the chiller and mechanical equipment room, 40’ for the distribution losses on the supply and return pipe, 20’ for the farthest coil and two-way control valve, and 0’ for the wide open balance valve.) I recognize the balance valve may have a foot of pressure drop and we need some means of preventing deadhead or 0 GPM, but those are negligible numbers for the example so I will not show them.

Let’s assume that the commons area is the closest two zones to the MER and the classrooms at the last 3 zones. Each of the coils shown could be a single AHU or multiple terminal units represented by the single zone.

We would normally represent the system with a control curve starting at 0 GPM at the DP sensor set point of 20’. Look at the curve. At 1000 GPM, the curve is at 80 feet. If every zone and terminal unit required the same amount of heating or cooling with no diversity, this representation of the curve would be perfect. If we controlled to this curve, everyone would be happy and zones would be satisfied. At 1000 GPM the pump would give 80 feet of head. At 500 GPM the pump would give 35 feet of head. All zone requirements rise and fall in the exact same percentage. BUT WAIT! What if there is diversity?

During the day, most of the flow rate is needed in the classrooms and very little is needed in the commons area. In the evening, there could be all sorts of activity in the commons area while the classrooms are empty. This system has a lot of diversity.

What should we do about pump control in this type of system? Does this control curve change? That is the subject of the next R. L. Deppmann Monday Morning Minutes.

Discover more on this Series:

HVAC Variable Speed Pump Curve Control: Part 2

Variable Speed Pump Area Control & System Diversity: Part 3

Variable Speed Pump Control & Automatic Balance Valves : Part 4