How will the weather in a northern climate affect the selection of the heat pump water heater with R-744 refrigerant? What about the Coefficient of Performance? What outdoor temperature will we use to manage the first cost and operating cost of the system? Today, the R. L. Deppmann Monday Morning Minutes looks at an example system in Ann Arbor, Michigan.

Heat Pump Capacity and the Northern Climates

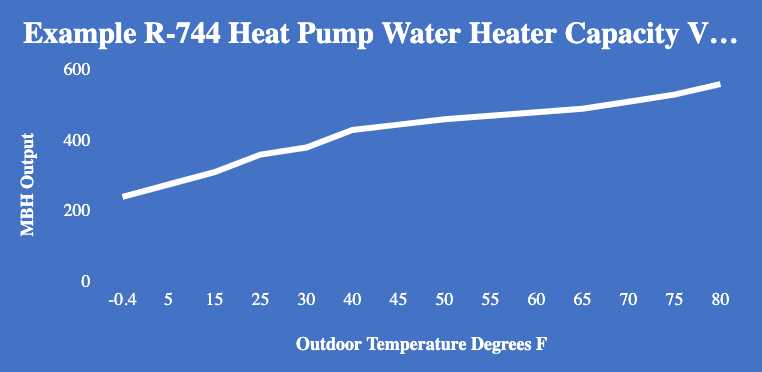

The capacity of air source heat pump water heaters changes with the weather, literally. The chart below is a representation of what a typical heat pump may provide at different outdoor air temperatures. A water heater that can produce 500,000 BTUH in the summer may only produce 250,000 BTUH at -4°F or 300,000 BTUH at 15°F.

The engineer will have to look at options if the temperature gets too low. This may be electric, gas, or another means of backup. There is more information on the previous blog, Heat Pump Water Heaters: Standby Capacity (Part 7).

The engineer must select the minimum temperature that the heat pump will run down to before the backup source of energy is used. Most of the time the backup is electric resistance heaters in the storage tanks.

Let’s say the heat load required was 600,000 BTUH when using 1000 gallons of storage. At -4°F the chart above would suggest the need for three heat pumps along with the storage tanks. The wise engineer might decide to run the heat pumps down to +8°F OAT and only require two heat pumps. This will cut the cost of the heat pumps by 50% and that could represent hundreds of thousands of first-cost dollars.

How often will the heat pump require the backup electric resistance coils if we run out of capacity while the weather is below 8°F? Let’s look at an example location of Ann Arbor, Michigan.

Ann Arbor Michigan Typical Weather

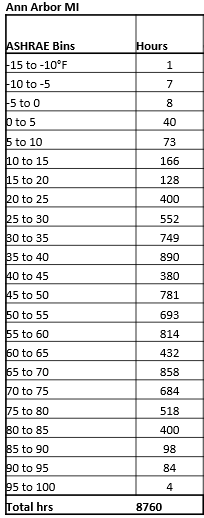

What penalty would the owner see if the heat pump ran out of capacity at -4°F compared with 8°F or even 30°F? Here is some ASHRAE weather data.

We can see that at -4°F, the lowest temperature for R-744 that the Lync by Watts product provides, the heat pump would not function for about 12 hours per year or 0.14% of the year.

The heat pump water heater would be short of capacity for 1,725 hours or 20% of the time if it was designed on 32°F OAT load.

At 8°F design, the heat pump would not provide the total required design BTUH for 56 hours or 0.64% of the year.

This all assumes that the system requires the 100% design load after the storage is used up.

Just a thought here. If the design load may only occur 5% of the year and the heat pump will not be able to meet that design for 0.64% of the year, should this be a discussion point with a savvy owner?

In addition, there is probably some standby backup capacity that could be used for the small percentage of probability that the issue even exists.

The Coefficient of Performance (COP) and Backup Electric Sources

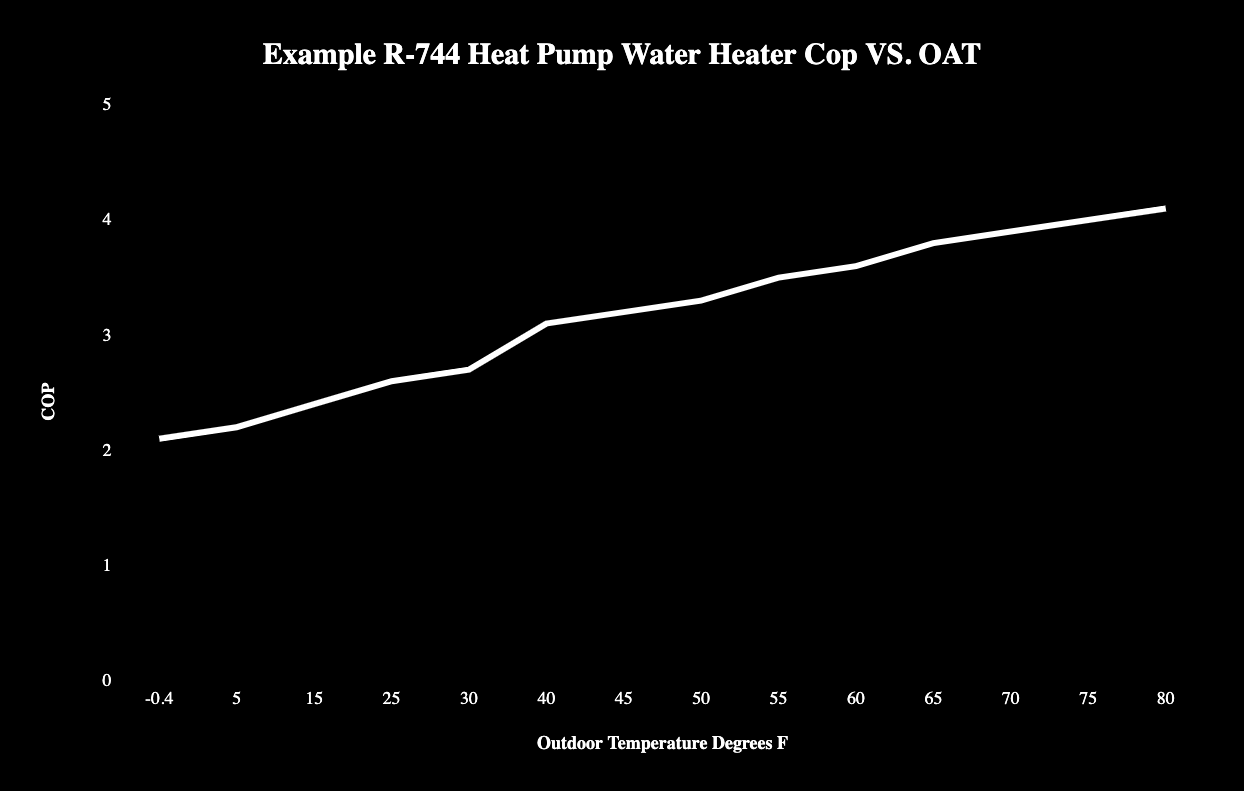

Using part of the backup or standby electric resistance heaters for the design load will drop the percentage of standby you have under a full load condition. During those times, the COP will drop to 1.0. The chart below is a representation of a heat pump COP at various outdoor air temperatures. Please note that this chart and the chart above are approximate representations. For the exact numbers, contact the manufacturer’s representative for the product you wish to specify.

Here are some numbers keeping with the example of Ann Arbor, Michigan. There are 12 hours per year when the weather is expected to be below 4°F. That means the electric resistance heaters or existing gas-fired water heaters will operate at a COP of 1.0 for 12 hours per year based on the chart from ASHRAE. Some years may be more, and some years may be less.

At -4°F the Lync by Watts COP is about 2.1. For every $1.00 of electricity KWH, the owner will get $2.10 worth of heated water. During the 12 hours, the heat pump is off, the owner will not get this benefit.

The engineer should be concerned if a heat pump manufacturer says the heat pump will work to a very low temperature but the COP at that temperature is 1.0. It may simply mean that there is an electric resistance heater at the low temperature.

Extra Capacity at Higher Temperature

Another thought is that availability of extra capacity in the summer. Assume the engineer decides to use the two 300,000 BTUH heat pumps in the design when it is extremely cold outside. Look at what happens in the summer. We could have 500,000 BTUH of capacity for each of the two heat pumps. Even at the hot water design load, that is 400,000 BTUH extra we could use somewhere else. Now imagine there are large periods of time with little or no plumbing hot water use. There could be a million BTUH to be used somewhere else. Those BTUs would cost a quarter of what an electric resistance load would cost. Nice return on investment there!

These are all things that the engineer and the manufacturer’s representative can discuss to reach some middle ground of first cost vs. lifetime cost vs. carbon-producing appliances. Next week we will use the Ann Arbor example and compare the costs of the R-744 heat pump vs gas-fired and electric resistance water heaters.

Part 1: Heat Pump Water Heaters: The Road to Decarbonization

Part 2: Heat Pump Water Heaters: How They Work

Part 3: Heat Pump Water Heaters: Refrigerants and Weather

Part 4: Heat Pump Water Heaters: Temperatures & Storage

Part 5: Heat Pump Water Heaters: Parts & Pieces & Storage