We continue to examine the double suction pump specification for HVAC and hydronic systems. Your specification may have a paragraph or two about the shaft, bearings, impeller, and wearing rings. What are you specifying and why? You might ask: “Can all the pumps I list meet my own specification?” Today’s R. L. Deppmann Monday Morning Minutes will help you understand how and why you specify these rotating elements of the pump.

We continue to examine the double suction pump specification for HVAC and hydronic systems. Your specification may have a paragraph or two about the shaft, bearings, impeller, and wearing rings. What are you specifying and why? You might ask: “Can all the pumps I list meet my own specification?” Today’s R. L. Deppmann Monday Morning Minutes will help you understand how and why you specify these rotating elements of the pump.

If these terms are new to you, check out a previous article on the differences between single and double suction pumps.

The Impeller Specification

The impeller specification can be very wordy or simple. The important points are the materials of construction, having it keyed to the shaft and the balance. Many manufacturers use different grades of material, but the two main materials are bronze and cast stainless steel. The only reason to go beyond that is in the case of plumbing systems, where we want the specification to include a “low-lead” pedigree.

Most of us know what a wobbly wheel looks like going down the street. It is an invitation for a break down resulting in more repair costs. Just like the wheels on your car, an impeller is balanced before it is installed in the pump. It does no good to use adjectives in a specification. How do you measure comments such as, “The impeller shall be balanced ‘real good’ or ‘exceptionally’?” Pump people use the Hydraulic Institue (HI), American National Standards Institute (ANSI), International Organization for Standardization (ISO). So your specification should request hydraulic and dynamic balance to an ISO G6.3 or better standard. This is the standard for pump impellers. The lower the number, the less vibration.

The Double Suction Pump Shaft

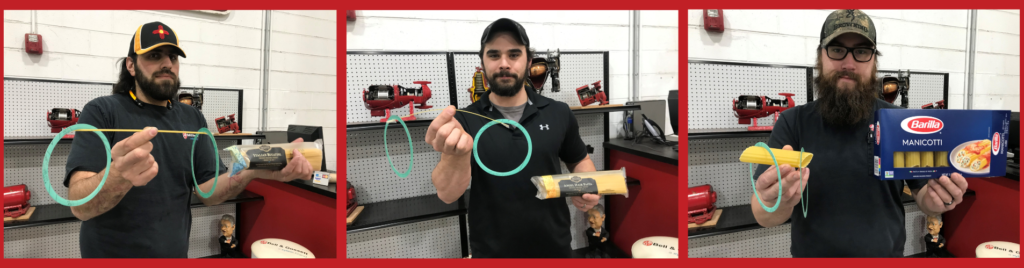

The concerns for the pump shaft are deflection and corrosion protection. Let’s start with the bigger issue, shaft deflection. Take a look at the three photos below. These may seem silly but it gets the point across and may make you laugh (both good things). The photo in the center, held by Dan Smith has a long skinny shaft and therefore has a lot of deflection. The left photo modeled by Steve Mama is the same length but is thicker so it has less deflection. The right photo by our birthday boy, Nick Lindon, shows the effect of a large diameter shorter shaft with virtually no deflection.

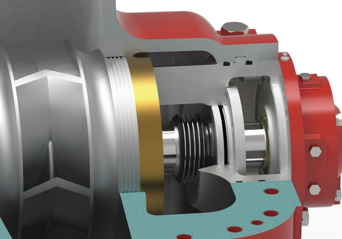

Shaft deflection will cause strain on the seals and bearings which will result in frequent repair and downtime for your client. Shaft deflection is stated as the L/d or Length over diameter ratio. The smaller the ratio, the better. Bell & Gossett designed the e-HSC double suction pump with an L/d ratio of 14 or better. This may or may not be proprietary so what do you need if the ratio is larger?

Shaft deflection will wear the bearings faster. As the bearings wear, the shaft moves in more of an elliptical motion. The goal is to avoid damaging the impeller or casing before you repair the pump. So if the L/d ratio is greater than 14, the pump should have casing and/or impeller wear rings. These are sacrificial pieces of metal which will wear and can be replaced in pumps with larger L/d ratios. So, a pump in the simple HVAC applications should have either a small L/d or wearing rings.

Obviously, we can use what older people call the “belts and suspenders” approach, but that will add much more cost and lead time. You are making decisions on how to spend your clients’ money and this is just a hydronic heating and cooling system, not a nuclear submarine. B&G spent the money to provide a better L/d ratio while others spent it on wearing rings.

The Pump Shaft Material and Sleeve

The pump shaft should be protected from corrosion and damage when the bearings start to fail. This protection, in our industry, is provided through the materials used. Let’s face it, the atmosphere in a hospital mechanical room is not an issue. We are protecting the shaft against the fluid in the system. We either want the shaft to be steel with a stainless steel sleeves at the bearings and seal or we want the shaft to be a high grade of stainless steel. One or the other is OK. Both are acceptable and different pump manufacturers use different methods.

The Double Suction Pump Bearings

The bearing specification could be long, complicated, and difficult to understand. The real importance is that bearings handle both radial and thrust loads. Another important thing is that they are protected from dirt. Most bearings are regreasable.

Bell & Gossett offers another advantage. The bearings and seals can be inspected and replaced without removing the heavy upper casing of the pump. This saves your client labor, time, and money! There are few manufacturers of double suction pumps that have this benefit. If you end up with the B&G e-HSC or VSX double suction pump, you win!

So what does this portion of the specification look like? At the end of this series of articles, I will provide a complete specification, but here are some double suction pump specification points:

- Impeller: shall be of the enclosed double suction type made of brass or stainless steel, both hydraulically and dynamically balanced to ISO 1940-1:2003 balance grade G6.3 and keyed to the shaft.

- The shaft: shall be a solid heat treated 420 stainless steel or steel with 304 SS sleeves. The ratio of length to diameter of the shaft design shall be no greater than 14 to minimize shaft deflection and maximize bearing and seal lives. If the L/d ratio is greater than 14, the pump shall be supplied with wear rings.

- A bearing housing: shall supply support for a pair of heavy-duty regreaseable ball bearings. The bearing set shall absorb thermal expansive forces and both radial and thrust loads.

- Bearings and seals: shall be replaceable without disturbing the system piping, the upper casing half, and shall be regreaseable without removal of the bearings from the bearing housing. (This portion will limit manufacturers)

Need to catch up? Check out last week’s Monday Morning Minute on mechanical seal specification.

Next week the R. L. Deppmann Monday Morning Minutes will continue with a look at bases, couplers, and installation of Double Suction Pumps.