The Department of Energy (DOE) Standards for centrifugal pumps will start to affect construction projects that you are designing today. These standards for minimum pump efficiencies go into effect January 1, 2020. If your project will have pumps shipped after January 1, they will be subject to the new rules. It’s time to look at specifications.

The Department of Energy (DOE) Standards for centrifugal pumps will start to affect construction projects that you are designing today. These standards for minimum pump efficiencies go into effect January 1, 2020. If your project will have pumps shipped after January 1, they will be subject to the new rules. It’s time to look at specifications.

It is hard to believe that the last time I wrote about this subject was in 2016! Let’s start with a brief review of what the DOE requires pump manufacturers to do next year. The standard requires that certain pumps meet a minimum efficiency through a ratio which is called PEI or Pump Efficiency Index. The rules further indicate that acceptable PEI ratio is identified on the pump tag.

What Pumps are Affected?

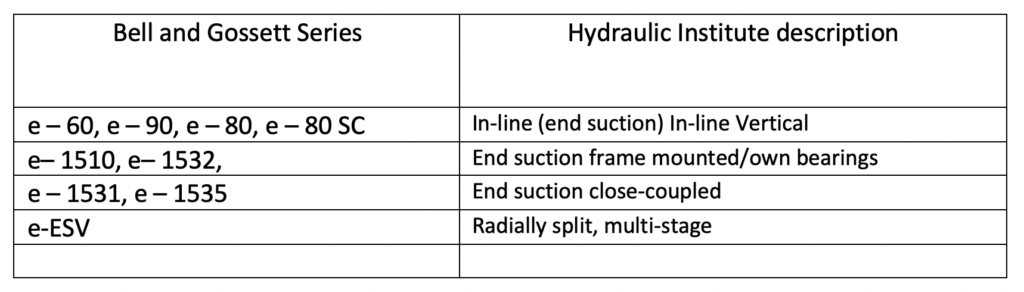

The DOE standards only affect certain styles of pumps. These pumps have certain limitations inside of the standard. Here is a simple chart showing the Bell and Gossett series of pumps that are affected by the DOE requirements.

Elimination of Inefficient Pumps

The original intent of this standard was to eliminate the bottom 25% of inefficient pumps. The DOE evaluates all pumps included, with what they refer to as PEI. The PEI-CL is a test where you take the pump and measure its average efficiency at several operating points along the impeller curve at a single speed and compare that with the minimum for that size pump. If your pump does not meet the minimum requirements, you cannot sell it. This will clearly eliminate some inefficient pumps and help promote a greener footprint.

Loopholes, Loopholes, Loopholes!

The DOE ended up building a loophole which, I am sure was not intentional. I believe the DOE understands clearly that a pump installed in a variable load application will save more money than one at a constant flow rate. There is much more savings if it has a variable speed drive on it compared to operating with the starter at constant speed. All hydronic engineers working on heating and cooling systems clearly understand this fact. It has been part of the code and ASHRAE standards for many years. So how does this present a loophole?

If a pump manufacturer supplies a pump with a variable frequency drive, they can test the pump at multiple speeds as the load drops down. If this saves more energy than the pump riding its impeller curve, they don’t need to improve the efficiency of the pump. The solution is to supply the pump with a variable frequency drive.

I would call this a loophole since you can still supply your inefficient pump, but now test it with a drive on it. So, how does this improve the green footprint? In 2019, without the standard, your client could receive a pump that is inefficient but met your specification. Often times, that pump would be shown with a drive on it by the pump supplier or by a drive supplier or by the controls contractor. In 2020, now with a standard in place, your client can still receive the same inefficient pump with a drive on it. The only difference is the manufacturer has to supply the drive.

What really changed? Sounds like a loophole in my opinion! To get a more efficient pump in 2020 the testing has to be at a single speed.

For more detail on this, you can review the article; Pump Efficiency Standards: Calculating PER Values.

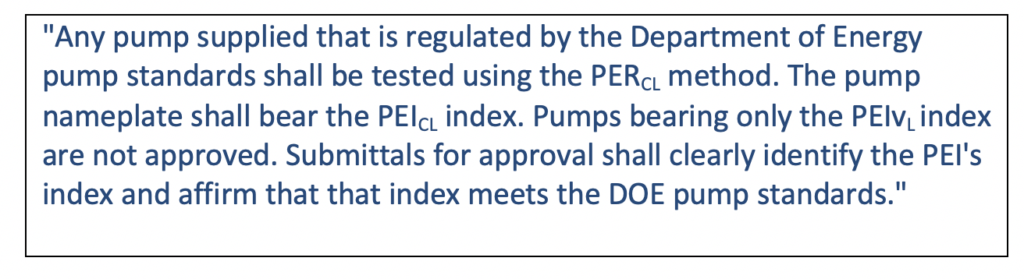

Energy Efficient Specifications

In 2020, the minimum required by the engineer will be to make sure the pump can meet the DOE standard whether the application is variable speed or constant speed. If you really want to improve the efficiency in your heating and cooling systems, you will have to take it one step further. Specify that the pump is tested and name-plated with a PEICL rating that meets the DOE requirements. This assures that you will receive a pump with improved efficiency whether it is operated at constant or variable speed.

In 2020, the minimum required by the engineer will be to make sure the pump can meet the DOE standard whether the application is variable speed or constant speed. If you really want to improve the efficiency in your heating and cooling systems, you will have to take it one step further. Specify that the pump is tested and name-plated with a PEICL rating that meets the DOE requirements. This assures that you will receive a pump with improved efficiency whether it is operated at constant or variable speed.

Many manufacturers, including Bell and Gossett, have spent the resources to improve the efficiency of their pumps. A high-efficiency pump on a variable load system with a properly controlled variable speed drive will save energy. The pump will save more energy than a less efficient pump on the same variable load system with a properly controlled variable speed drive.

It makes sense to specify a pump that was tested under the constant load testing requirements. It also makes sense to demand the pump that is named-plated to meet the DOE requirements under the constant load test.

Specify the following:

For more information about PEI, check out the article on Pump Efficiency Standard: The Pump Energy Index (PEI).

Hydraulic Institute Energy Rating Database

Head to the following link for Pump manufacturers who have submitted their data to the Hydraulic Institute Energy Rating Database.

If you enter this database:

- leave the rating ID and basic model number blank

- Hit the down arrow under the participating organization

- Hit the down arrow under the brand

This will populate a listing of the pumps submitted, including their Hydraulic Institute energy rating, and just underneath that, you will find the PEI for both CL and VL.

Read More on the Department of Energy Standards Series:

- Part 1 – Pump Efficiency Standards: They’re Here, Now What?

- Part 2 – Pump Efficiency Standards: The Pump Energy Index (PEI)

- Part 3 – Pump Efficiency Standards: Calculating PER Values

Check out our recent Monday Morning Minute on Domestic Water Recirculation for Residential and Small Commercial Systems.

Stay tuned for next week’s Monday Morning Minute on the Double Suction Pump!