The weather is warming, and our attention turns away from heating and toward system air conditioning. To protect the cooling tower pumps, we offer a couple of quick suggestions for starting up the cooling tower systems.

Protecting the Pumps During Cooling Tower Startup

Many cooling towers are drained in the winter. The outdoor piping from the tower pan to the inside must be filled with water. Some portion of the discharge pipe from the condenser to the tower inlet is also empty and must be filled. Too often, during startup, the tower pan is filled, and the pumps are started to push the water up to fill the piping system.

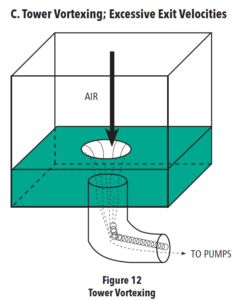

Cooling tower pump duty is rough under ideal conditions. The pan level drops quickly when we take water from the tower pan to fill a length of 8”, 10”, or 12” pipe. The makeup valve is not designed for that volume of flow rate. The result is a drop in tower pan level and vortexing. The air introduced during this vortexing can stall the pump, cause cavitation, and vibration. None of these are good for the pump life.

A Better Way to Fill the Tower Supply Header

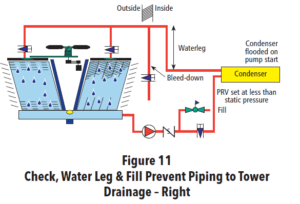

Look at this simple diagram from the Bell & Gossett Cooling Tower Pumping technical manual. Figure 11 shows a fill valve or PRV at the pump discharge. It is set to a pressure slightly greater than the elevation of the tower return header. The purpose is to fill the pipe with water before we start the pump. It is on the discharge of the pump so the check valve or triple duty valve will prevent the water from flowing through the pump and overflowing the tower pan.

Another thing to notice is the bleed-down tuning. The purpose is to identify when the pipe is full. The same thing can be accomplished by checking the tower pan. Water will start to fill in the tower pan once the system fills.

Now once the piping is full, fill the pan and continue your startup procedure.

Another Option to Fill the System

Often, the fill valve is not there. You can hook a hose up to a drain around the condenser to fill the system. Just make sure to crack open the hose bibb and not use full pressure.

After all this, sometimes the owner will still just use the pump to fill the system. If that must be how it is done, I’ll make a suggestion. Throttle the pump back using the variable frequency drive or the discharge valve. The goal is to keep the tower level from dropping quickly and allow the fill valve to keep up with the pump. Always make sure to mark the original location of the discharge valve so you can return it to the same position.

Cooling tower startup is always a sign that warmer weather is coming. I look forward to the warmer weather and happier cooling tower pumps because you followed these simple suggestions.