The combination of water usage and energy usage in open loop cooling towers are a significant cost to owners. Owners are faced with tremendous water utility costs and frown when they see cooling tower water regularly going down the drain. How much water can be saved? Would you believe thousands of gallons? Learn how cycles of concentration and reducing biofilm can impact your utility costs.

The combination of water usage and energy usage in open loop cooling towers are a significant cost to owners. Owners are faced with tremendous water utility costs and frown when they see cooling tower water regularly going down the drain. How much water can be saved? Would you believe thousands of gallons? Learn how cycles of concentration and reducing biofilm can impact your utility costs.

How Much Water Does A Tower Makeup?

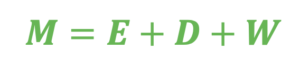

In addition to water emissions caused by evaporation and drift, cooling towers require blow-down to control the levels of dissolved minerals re-circulated in the cooling tower. These losses are offset or balanced by makeup water to both maintain the level of water in the tower and to maintain the correct level of dissolved minerals. This balance required can be expressed in formula as:

M = Makeup water

E = Water evaporated

D = Water lost to drift

W = Blowdown water

We addressed the drift and evaporation in the first part of this series. The blowdown water volume is all about the particulate left in the water basin and the build up of biofilm containing bacteria. Tower Tech will reduce the blowdown water consumption by reducing the environment for the bacteria to grow as well as increasing the cycles of concentration.

Increasing Cycles of Concentration

There is a lot written about the cycles of concentration (COC) term used in chemical treatment of cooling towers. Here is my simple explanation. If I have 2 gallons of water and I evaporate 1 gallon, I am left with 1 gallon of water. That one gallon of water has twice the amount of particulate or impurities since when the water evaporated it did not evaporate the impurities. That gallon of water has twice the “stuff” in it, so it has a COC of 2.

Now you add a gallon of water, so you are back to 2 gallons. A gallon evaporates. The gallon that is left now has 3 times the stuff in it. It now has a COC of 3.

Eventually, the cycles of concentration gets too high, and the water must be removed or blown down the drain. Tower Tech cooling towers can handle COC of 1-2 more than other designs. What does this mean for water use? Assume a tower requires a drain down at 4 COC. You now can change that to 5-6 COC using Tower Tech. That means you will save 25% of the water by delaying the blowdown. This can be significant.

More information is available in the article, “Increasing Cycles of Concentration”.

Reducing Biofilm

Tower Tech has a closed in basin design that basically eliminates the exposure of the basin water to sunlight. This eliminates the algae reproduction and blooms. The algae are an organic nutrient for bacteria.

The flow through basin design provides additional protection. The design allows water to move at 5-7 feet per second (FPS) velocity which exceeds the less than 3 FPS experts suggest is needed for reasonable biofilm growth. Less biofilm contributes to less need for water blowdown

More information is available in the “white papers” article, Tower Tech Modular Cooling Towers and Legionella Control.

How Much Water Can a Hospital Save?

We recently received communication from a hospital outlining how much water they saved in a season of cooling. Visit our project of the month, MCM Cooling Tower Saves Water, for a summary.

Next week, part 3 of the series will look at energy savings.

Part 1: Cooling Tower Design to Save the Planet: Drift Eliminators