Gas fired commercial water heaters come in a variety of materials of construction. Most available offerings fall into three categories. What are these materials and what do I need to know about them?

Gas fired commercial water heaters come in a variety of materials of construction. Most available offerings fall into three categories. What are these materials and what do I need to know about them?

Water Heater Tank Materials – A Snippet of History

Water Heater tank construction started with steel and cast iron which stored water which resulted in discoloration. The next improvement was in the use of galvanized tanks which was prevalent in the first half of the 20th century. At the same time there were tanks available in copper and copper lining. Each with their own unique limitations.

Glass-lined steel tanks in commercial applications were introduced in the 1950s and were in common use by the 1970s. There was even a “double glass-lined” tank which I read about in a Plumbing and Mechanical Engineer article.

The use of stainless steel in heat exchangers grew with the advent of condensing technology in water heaters. Along with that, some manufacturers began offering the tank in 316L and 304L stainless steel.

Today there is a new kid on the block. Duplex stainless steel is a better solution that combines the properties of both 300 series and 400 series stainless steel for longer life and corrosion resistance.

Glass Lined Tanks

Steel tanks with porcelain enamel (glass lining) are a good option for domestic hot water tanks. It has good protective qualities from corrosive fresh water. There are limits to the protection which I’ll mention later. The production process bakes the “glass” onto the tank.

There can be small gaps or fissures at the tappings. For this reason, anodes are critical when using glass-lined tanks. The anode attempts to reduce the fouling of the gaps near openings. Some manufacturers use a sacrificial anode of magnesium or aluminum. These must be inspected and replaced regularly, or you risk premature loss of the tank.

Obviously, there are many owners who do not do the inspections and replacement of anodes. If the rod is not inspected regularly, it may be difficult to remove without damaging the lining. A few manufacturers such as the Bock OptiTHERM use a better “powered” anode. This is not sacrificial if electric power is connected to the rod. It eliminates the replacement maintenance time.

One main concern with glass lining is temperature. The Bock OptiTHERM has a limit of 180⁰F before the tank is damaged. Many manufacturers are limited to 160⁰F. These temperatures are above the safe operation set point for domestic water. They may come into play during Legionella mitigation or with solar or heat pump applications.

ASPE’s chapter 19 defines “Gas Water Heaters – Instantaneous with Separate Tank” as one where the tank is separate from the heater. ASHRAE calls this a “Circulating tank water heater”.

Stainless Steel Tanks

Many tankless water heaters and almost all tank-type condensing water heaters use stainless steel heat exchangers due to the acidic condensate byproducts. Some manufacturers are using austenitic 316L stainless steel for the tanks.

Stainless steel needs no lining, so the “gaps” do not exist. There is no need for anodes in the tank. The stainless-steel tanks are also lighter. They are also less prone to damage during shipping and installation than fragile glass-lined tanks. They are not limited to the temperatures of glass lining.

Even the simplex stainless-steel tanks have limitations. Some water quality concerns may cause stress corrosion cracking of the metal. Excessive chloride is one example of concern.

Duplex Engineered Alloy Stainless Steel Tanks

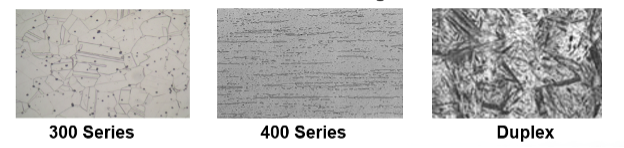

Technological advances happen very quickly in our lives. Even our plumbing industry advances in new and improved technology. Duplex engineered alloy is one of those advancements. This process takes the good features of 300 series or austenitic grain stainless and the 400 series ferritic grain stainless and combines them into the best alloy available.

Technological advances happen very quickly in our lives. Even our plumbing industry advances in new and improved technology. Duplex engineered alloy is one of those advancements. This process takes the good features of 300 series or austenitic grain stainless and the 400 series ferritic grain stainless and combines them into the best alloy available.

This process has been around for a while. Recently, a few manufacturers have devised a process to make duplex alloy water heater heat exchangers and tanks at a reasonable price level. The PVI AquaPLEX® engineered duplex alloy is one example. The addition of pickling and passivation processes in manufacturing provides even more protection. The price point is higher than glass or stainless but easily defended through owner benefits.

So, in the world of commercial water heater tanks, there are clear “good, better, and best” choices to match the plumbing engineer and client needs.