|

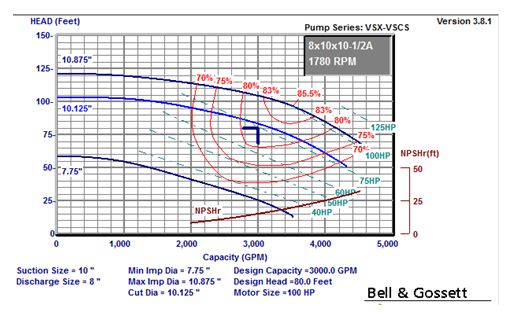

Last week the R. L. Deppmann Monday Morning Minute left you with a multiplier of 1.3, 1.5, or 2.0 to use with the pump NPSHR. Let’s look at an example this week using the suction energy formula we introduced last week and add one more margin to the formula. Let’s start with the additional margin. Tower water has a great deal of air entrained and that air can play havoc with the gauge pressure at the pump suction. How often have you witnessed the bouncing gauge in this situation? This is the reason I add 5 extra feet to the NPSHR as a safety factor. You may choose to add this or not, but I always start by adding it in. Now let’s look at an example. I suggest you have the last Monday Morning minute handy. Now, from the chart published in the last Monday Morning Minute, the multiplier to use with published NPSHR will be 1.3 and the recommended safety factor from statements above will be 5 feet. The NPSHR at 3000 GPM is 15 feet absolute from the curve above. We will want our available NPSH to be [[15 x 1.3 = 19.5 + 5 = 24.5]] feet absolute or greater. To learn more, check out one of these related articles below: Net Positive Suction Head (NPSH) – Terms and Definitions Where Cavitation Begins – Cooling Tower Pumps and Piping

|

Disclaimer: R. L. Deppmann and it’s affiliates can not be held liable for issues caused by use of the information on this page. While the information comes from many years of experience and can be a valuable tool, it may not take into account special circumstances in your system and we therefore can not take responsibility for actions that result from this information. Please feel free to contact us if you do have any questions.