Boiler Outdoor Reset and Effects on Condensing Boiler Efficiencies (Part 2)

| with edit by Norm Hall

Printer Friendly (PDF)

On November 9th we defined outdoor reset control. Today we will look at its positive effect on efficiency.

|

|

|

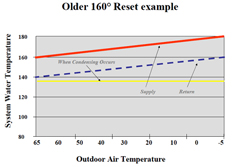

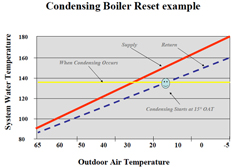

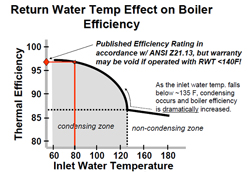

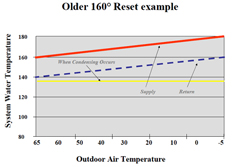

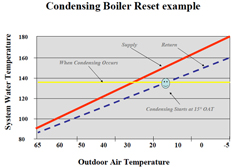

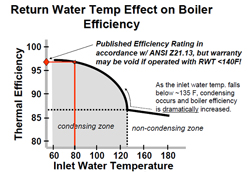

Using outdoor reset in buildings is nothing new. Reset was applied for smoother building temperature control. For many years it was accomplished using a three way mixing valve in constant flow systems with large fire tube or bent tube boilers which required no minimum flow rate. In the years past the lowest reset temperature of a boiler was often 160° supply water. With a 20° ΔT across the system, the return water would be 140° minimum. In non-condensing (older) boilers this is the lowest allowed return temperature to keep them from condensing. If you condense in a non-condensing boiler the life of the unit will be severely shortened due to the destructive acidic nature of flue gas condensate. By using today’s condensing boiler technology with heat exchangers designed for the acidic condensate, your building could, for example, use the reset ratio above with a supply water temp of 120° at an outdoor temperature of 40°. At this supply temperature and using a 20° ΔT system design, the return water would be coming back at 110°or even lower.

As the boiler return water is lowered below 140 degrees condensing starts to occur and in a condensing boiler the efficiency is increased. We will continue this example next week. |

|

Thank you for using products sold by R. L. Deppmann Company in Michigan and Ohio!

Disclaimer: R. L. Deppmann and it’s affiliates can not be held liable for issues caused by use of the information on this page. While the information comes from many years of experience and can be a valuable tool, it may not take into account special circumstances in your system and we therefore can not take responsibility for actions that result from this information. Please feel free to contact us if you do have any questions.

Archives – Click here for Past Articles