Addition of a Mixing Valve

During the last 6 weeks, the R. L. Deppmann Monday Morning Minutes concentrated on re-circulation systems where the supply temperature to the system was the same as the outlet temperature of the water heater. Today we will examine the addition of a Lawler master mixing valve in the system.

Lawler manufactures a wide variety of thermostatic mixing valves exceeding the ASSE 1017 standards.

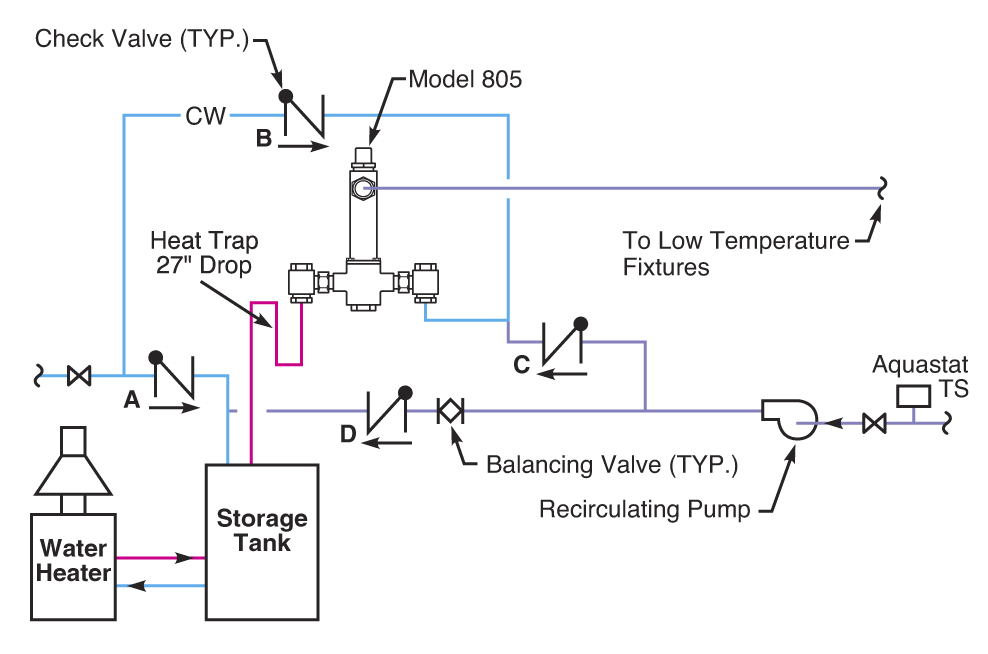

The re-circulated hot water is normally pumped into the cold water line entering the water heater for systems without mixing valves. During periods when the re-circulating system is needed there is no draw or load on the system. No water is leaving the system and it acts similar to a closed hydronic system. If the return line is only piped to the hot water side of the mixing valve, there would be no water flow on the cold side to blend and mix.

Rule #1: Always pipe the hot water return into the cold water supplies to the mixing valve and to the hot water heater.

One key point of understanding is the way the mixing valve operates under the low flow condition in a re-circulating system. At low flows, the mixing valve in the mechanical equipment room will hunt in an effort to control temperature. If the flow rates on the hot and cold side are equal, eventually the mixed temperature leaving the mechanical room will be too hot.

Let’s look at an example. Assume the water heater is at 140°F supply, the mixed temperature is at 120°F and the domestic water recirc system is designed for a 10 degree ΔT or 110°F return. When the mixing valve was set ,we could assume the cold water was at low temperatures such as 40°F. If the flow was equal on both the hot and cold sides of the mixing valve, the temperature would be (50% X 140) + (50% X 40) = 100% at 90 which is too cold. In order to get our 120°F, the valve is “balanced” with three times more hot water than cold water. But in the re-circulating mode, the return water is not 40°F but 110°F! The three times balance o

n the hot water side can cause the supply temperature to greatly exceed the design during no-load conditions. The designer has to do something to correct this imbalance at no-load conditions. For this reason, Lawler suggests the addition of a balance valve on the return to the hot water heater. Rule #2: Always put a balance valve on the return line to the water heater side. This valve would be set for a safe supply temperature, in case there are differences between the design and the installed system

We would also suggest a balance valve on the pump discharge, so we can read the total flow in the return line.

Next week, let’s look at the concern over changing performance conditions in mixing valve applications

Disclaimer: R. L. Deppmann and it’s affiliates can not be held liable for issues caused by use of the information on this page. While the information comes from many years of experience and can be a valuable tool, it may not take into account special circumstances in your system and we therefore can not take responsibility for actions that result from this information. Please feel free to contact us if you do have any questions.