| Printer Friendly (PDF)

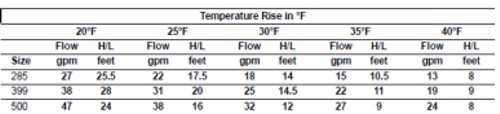

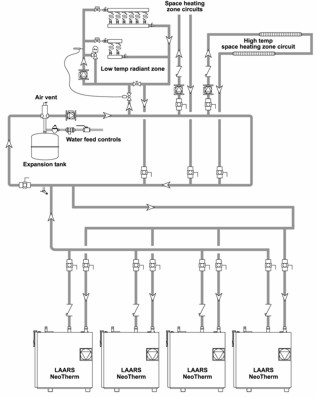

Last week, this series of articles, outlined Primary Secondary Piping. Laars NeoTherm condensing high efficiency boilers uses primary secondary piping arraignments in their installation. Please refer to Laars manual 1218B before installing this product, since it contains complete instructions and safety precautions. The NeoTherm may have a boiler mounted pump or a separate pump, supplied by others. This is the primary pump and is used to keep a constant flow of water though the boiler for a given temperature difference. If the flow rate is outside the design specifications of Laars, there will be operational problems or damage to the boiler. As an example, the chart below shows a 24 GPM in a 500,000 BTUH input Neo with a 40°F ΔT and 47 GPM for a 20°F ΔT requirement.

Table 1: Flow rate chart from Laars document 1217D for NeoTherm Boilers When piping these condensing boilers, it is important to use primary secondary piping and keep the pipe length to a minimum. This assures there is no affect on the boiler flow (primary), as the system flow rate (secondary) changes. In multiple boiler systems, it is advantageous to pipe condensing boilers in such a way that all boilers see the lowest inlet temperature. The lower the inlet temperature to the boiler, the higher the efficiency will be. |

|

Thank you for using products sold by R. L. Deppmann Company in Michigan and Ohio!

Disclaimer: R. L. Deppmann and it’s affiliates can not be held liable for issues caused by use of the information on this page. While the information comes from many years of experience and can be a valuable tool, it may not take into account special circumstances in your system and we therefore can not take responsibility for actions that result from this information. Please feel free to contact us if you do have any questions.

Archives – Click here for Past Articles