| Printer Friendly (PDF)

One universal fact about sump and sewage pumping systems is that no one wants to go into the sump to pull out a pump for maintenance! Today we will discuss pump guide rails or lift out assemblies which allow the service person to disengage the pump from the discharge piping and lift the pump out of the sump. These lift out products go under a number of different names such as; guide rail assembly, base assembly, lift out assembly, or slide rail assembly. They all work through a sliding coupling at the pump discharge and they all require the sump to be a minimum diameter so all the hardware can fit in the sump.

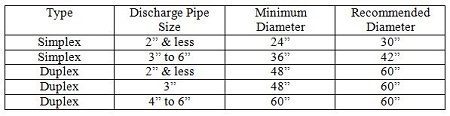

When specifying ITT Bell and Gossett guide rail assemblies, make sure you include the stainless steel chain and shackle for lifting the pump out. The assembly should match both the pump size and the selected pipe size. There is a great deal of hardware to install in the sump basin. There must be room for the elbow, pump, slide rail, floats, brackets, and room for clearance when removing the pumps. For this reason, B&G recommends the following minimum sump diameters when using guide rail systems.

Next week the article will address pump minimum run time and sump sizing. |

|

Thank you for using products sold by R. L. Deppmann Company in Michigan and Ohio!

Disclaimer: R. L. Deppmann and it’s affiliates can not be held liable for issues caused by use of the information on this page. While the information comes from many years of experience and can be a valuable tool, it may not take into account special circumstances in your system and we therefore can not take responsibility for actions that result from this information. Please feel free to contact us if you do have any questions.

Archives – Click here for Past Articles