High Rise Considerations

The last article, part 4, showed an example of a high rise system with pressure reducing valves (PRVS) and their effect on the recirculating pump sizing. The addition of PRVS also adds a complexity to the setting of balance valves in the system. If the valves are not properly set, complaints about the time it takes to get how water on some floors could be a real problem for the facilities engineer or maintenance staff.

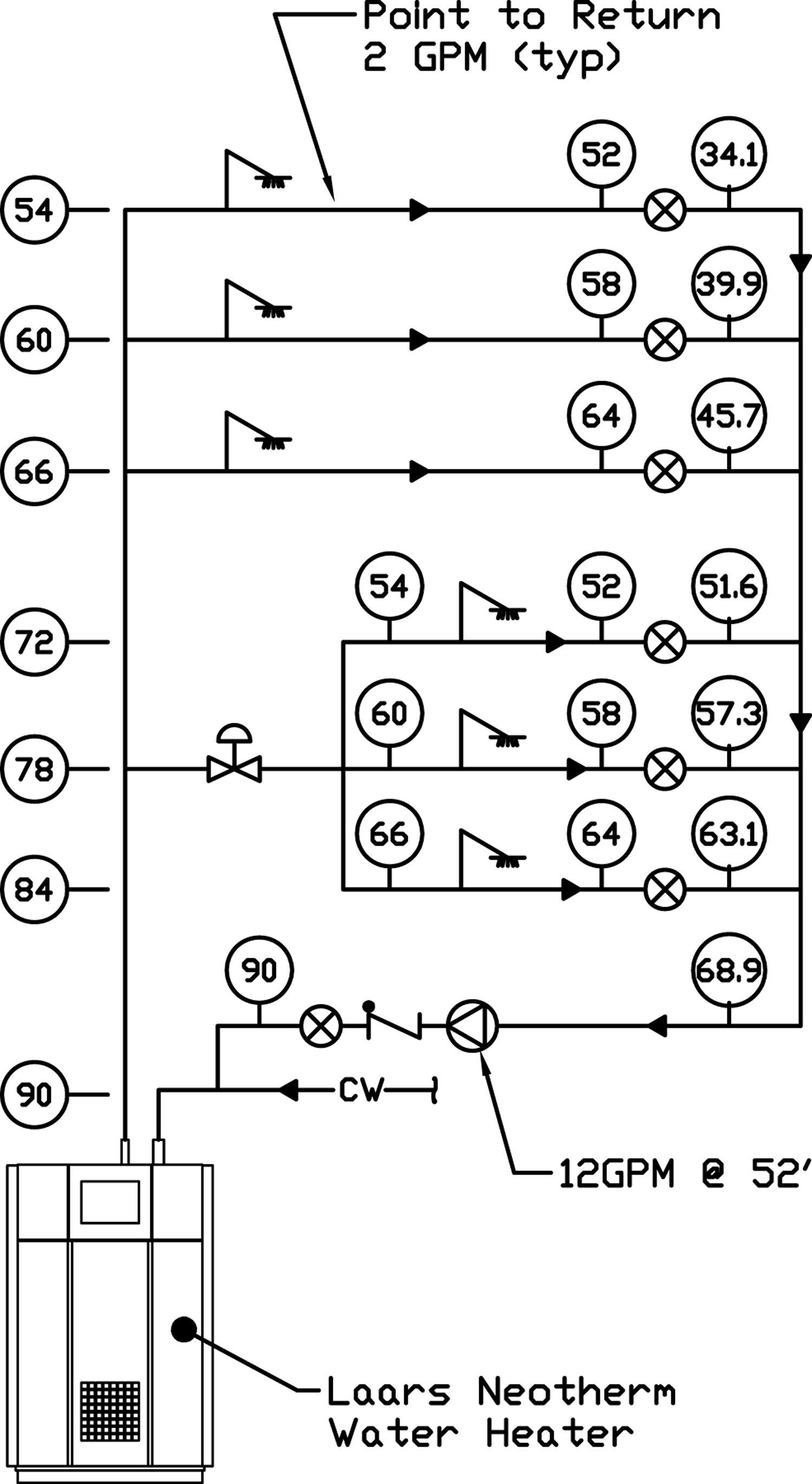

Figure 1 shows a high rise system with a PRV. Figure 1 also shows the balance valves. Using the information provided in the first few articles of this series we can determine the pump head due to friction losses (PD) in the piping system. In this example I assume 4.6 feet (2 PSIG PD) on each floor, 1 foot (.4 PSIG) for the balance valve, and 4 feet (1.8 PSIG) for the return riser and MER for a total of 9.6 feet. Using the information in part 4 of the series we also determined the pump head pressure reducing valve loss to be 18 PSIG or 41.6 feet. Our example assumes we determined the flow rate required to be about 2 GPM per floor for a total of 12 GPM.

How to Pre-determine the Balance Valve Settings

I’ve worked backwards through the system to determine the expected pressures on the return side of the recirculation system. The difference between the pressure required at the balance valve discharge and the pressure expected at the balance valve inlet is the pressure drop required at the balance valve.

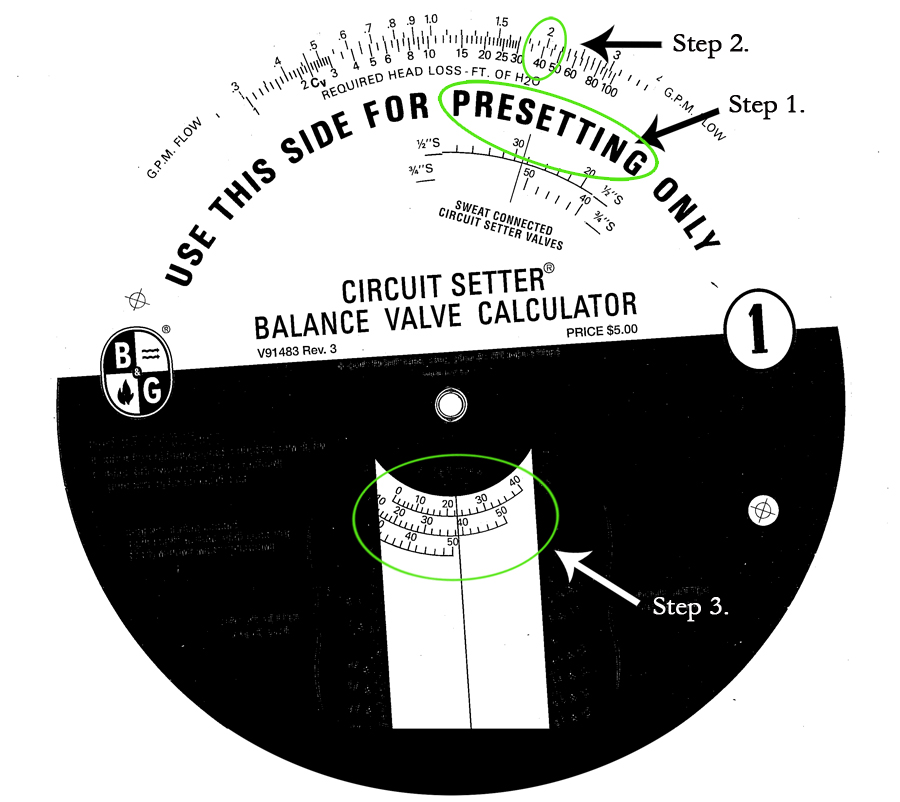

The B&G lead free Circuit Setters can be preset as they are installed. This will save field labor by keeping the balance modifications needed when you read out the valves to an absolute minimum. Let’s use the 6th floor balance valve as an example. In this example the inlet pressure is 52 PSIG and outlet required is 34 PSIG giving a difference of 18 PSIG or 42 feet. Step 1 – locate side 1 of the wheel. Step 2 – Rotate the wheel so 2 GPM and 42 feet are aligned. Step 3 – set the CB-3/4LF to 39 degrees. It’s that easy.

If you haven’t done this before, try it on your next project. Your Deppmann sales engineer can help you with the calculations.

Next week we look at ways to avoid this huge pressure drop across balance valves.